Exploring the Advantages and Applications of Tinned Copper Power Cables

Introduction

In the realm of electrical engineering and power distribution, the choice of the right materials for cables is crucial to ensure the efficiency, safety, and reliability of electrical systems. Among the various options available, tinned copper power cables have gained significant popularity due to their unique properties and benefits. This article aims to delve into the world of tinned copper power cables, exploring their composition, advantages, applications, and the reasons behind their widespread use in diverse industries.

Composition and Structure of Tinned Copper Power Cables

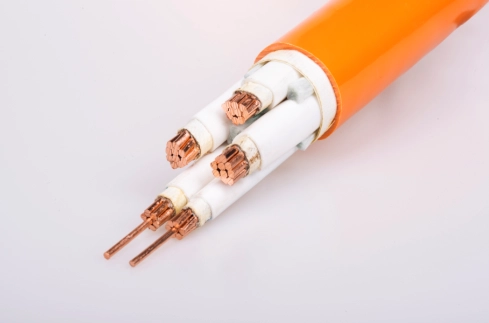

Tinned copper power cables are made from high-quality copper conductors that are coated with a thin layer of tin. This tinning process involves immersing the copper wires in a bath of molten tin, which creates a protective barrier around the copper core. The tinning process enhances the properties of the copper conductor and provides several advantages over bare copper cables.

The structure of a tinned copper power cable typically consists of multiple tinned copper conductors twisted or laid together, insulated with a suitable material such as PVC, XLPE, or rubber, and sheathed with a protective outer layer. The combination of tinned copper conductors and robust insulation materials results in a durable and reliable cable that can withstand various environmental conditions and mechanical stresses.

Advantages of Tinned Copper Power Cables

1. Corrosion Resistance: One of the key advantages of tinned copper power cables is their superior resistance to corrosion. The tin coating acts as a barrier that protects the underlying copper conductor from oxidation and environmental degradation. This corrosion resistance makes tinned copper cables ideal for outdoor applications and harsh environments where moisture and corrosive substances are present.

2. Solderability: The tin coating on copper conductors improves their solderability, making it easier to create strong and reliable connections during installation. This solderability is particularly advantageous in applications where precise and secure electrical connections are essential, such as in electrical panels, control systems, and industrial machinery.

3. Thermal Stability: Tinned copper power cables exhibit excellent thermal stability, allowing them to maintain their electrical properties and performance over a wide range of temperatures. This thermal stability makes tinned copper cables suitable for high-temperature applications and environments where temperature fluctuations are common.

4. Flexibility and Ductility: The tinning process enhances the flexibility and ductility of copper conductors, making tinned copper power cables easier to bend, route, and install in tight spaces. This flexibility is beneficial in applications that require complex cable routing or where space constraints are a concern.

5. Electrical Conductivity: Copper is renowned for its high electrical conductivity, and tinned copper power cables retain this property due to the underlying copper core. The tin coating does not significantly impede the flow of electricity, ensuring efficient power transmission and minimal power losses in electrical systems.

6. Rubber Sheathed Cable and Reliability: Tinned copper power cables are known for their longevity and reliability, with a lifespan that exceeds that of many other types of cables. The combination of corrosion resistance, thermal stability, and robust construction ensures that tinned copper cables can endure years of service without significant degradation in performance.

Applications of Tinned Copper Power Cables

Tinned copper power cables find a wide range of applications across various industries and sectors due to their numerous benefits and versatile properties. Some common applications of tinned copper cables include:

1. Marine and Offshore: Tinned copper power cables are well-suited for marine and offshore applications where exposure to saltwater, humidity, and harsh weather conditions can lead to accelerated corrosion of cables. The corrosion-resistant properties of tinned copper cables make them ideal for use in shipbuilding, offshore oil platforms, and marine electrical systems.

2. Renewable Energy: With the increasing focus on renewable energy sources such as solar and wind power, tinned copper power cables play a vital role in connecting solar panels, wind turbines, and other renewable energy systems to the grid. The corrosion resistance and longevity of tinned copper cables make them a reliable choice for renewable energy installations.

3. Industrial Machinery: Tinned copper power cables are commonly used in industrial machinery and equipment due to their excellent thermal stability and electrical conductivity. These cables can withstand the high temperatures and electrical loads present in industrial environments, making them essential for powering motors, pumps, and other heavy-duty machinery.

4. Telecommunications: Tinned copper cables are also utilized in telecommunications systems and data networks where reliable signal transmission is paramount. The solderable nature of tinned copper conductors ensures secure connections in telecommunications infrastructure, helping maintain the integrity and efficiency of communication networks.

5. Automotive and Aerospace: In the automotive and aerospace industries, tinned copper power cables are employed in vehicles, aircraft, and spacecraft for their lightweight construction, high conductivity, and resistance to vibration and mechanical stress. Tinned copper cables are used in automotive wiring harnesses, avionics systems, and other critical electrical components.

6. Power Distribution: Tinned copper power cables play a crucial role in power distribution systems, including electrical substations, power plants, and utility grids. The corrosion resistance of tinned copper cables ensures long-term reliability in power distribution networks, reducing the risk of downtime and maintenance costs.

Conclusion

Tinned copper power cables offer a host of advantages that make them a preferred choice for various applications in industries ranging from marine and renewable energy to telecommunications and automotive. The corrosion resistance, solderability, thermal stability, and electrical conductivity of tinned copper cables set them apart as reliable and durable solutions for powering electrical systems in diverse environments. As technology continues to advance and the demand for efficient and sustainable power transmission grows, tinned copper power cables are poised to remain a cornerstone of modern electrical infrastructure.