Discovering the Intricacies of PCB Manufacturing Refine

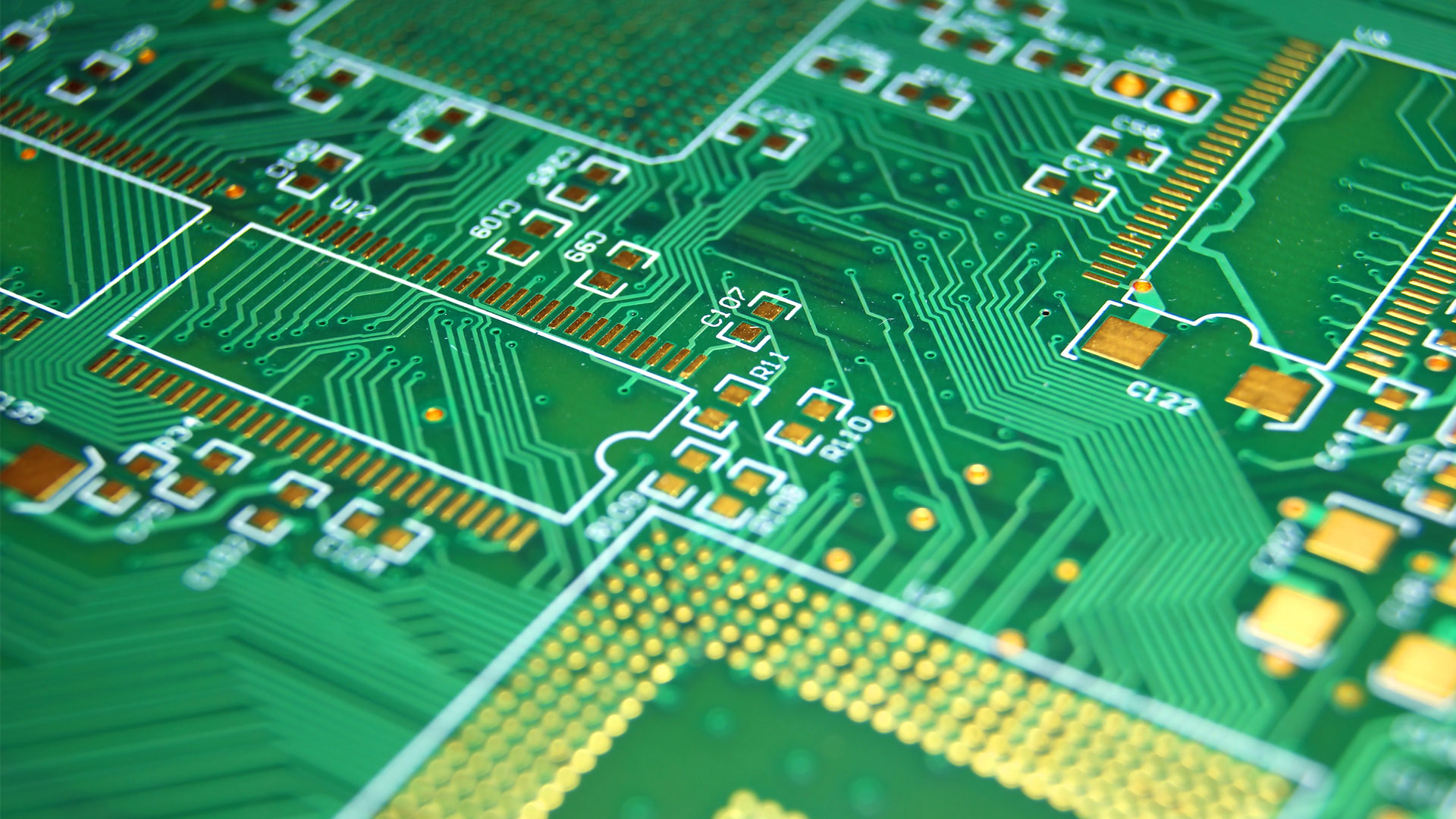

The manufacturing of Printed Circuit Boards (PCBs) is a complicated procedure that entails countless steps, each important to the capability and dependability of the final product. This short article aims to supply an extensive introduction of the PCB production process.

Layout and Pre-Production Planning: The journey of PCB manufacturing starts with design. Utilizing customized software application, designers develop a comprehensive blueprint of the board, which includes the layout of elements, connections, and various other critical features. This stage typically includes a complete review to make certain the style meets all demands and is optimized for manufacturability.

Creating the Substrate: The base material, typically comprising epoxy material and glass fiber (FR4), is prepared. This substrate forms the core of the PCB, providing structural integrity and insulation in between the conductive layers.

Pattern Transfer: The next action includes moving the circuit design onto the board. For inner layers of multilayer PCBs, this is done by finishing the substratum with a light-sensitive film, onto which the layout is printed making use of a UV light. The unexposed areas are then etched away, leaving the copper pattern.

Layering and Lamination: In multilayer PCBs, several layers of product, including copper aluminum foil and prepreg (pre-impregnated with material) layers, are piled together. The pile undergoes heat and pressure, creating the prepreg to melt and bond the layers into a single, solid framework.

Boring: Openings are drilled into the PCB to permit the installing of components and to produce vias, which are electrical connections in between different layers of the board. This procedure needs high accuracy to ensure positioning and avoid harming the interior layers.

Layering and Copper Deposition: The drilled PCBs go through electroplating, which deposits a thin layer of copper externally and inside the holes. This step is crucial for developing a great electrical link with the vias.

Outer Layer Imaging and Development: Comparable to the inner layers, the external layers are coated with a photosensitive film. The outer layer design is after that printed onto this film, and the board is developed to get rid of unexposed areas, revealing the copper pattern.

Etching: PCB board supply exposed unwanted copper is etched away, leaving behind the desired circuit pattern. This step has to be thoroughly regulated to ensure the precision of the circuit style.

Solder Mask Application: A solder mask is applied to the board, covering the whole surface area except for the areas where soldering will certainly happen, such as component pads and vias. This layer shields the copper from oxidation and avoids solder bridges in between very closely spaced conductive components.

Surface area Complete: The PCB gets a surface area finish, which can differ depending upon the application. Common coatings include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives). This coating shields the revealed copper circuitry and ensures an excellent solderable surface area.

Silkscreen Printing: Crucial information such as element tags, examination points, and logo designs are printed on the PCB using a silkscreen process. This action includes a layer of ink to the board, usually on the part side, to help in assembly and screening.

Testing and Quality Control: The last action in PCB production is testing and examination. This can include Automated Optical Assessment (AOI), X-ray inspection, and electrical testing to ensure the PCB satisfies all specs and is free from problems.

Assembly and Final Examination: If the PCB is to be delivered as a total assembly, elements are then placed onto the board through processes like SMT (Surface Area Mount Technology) or through-hole technology. A last evaluation is conducted to make certain the assembly satisfies the called for requirements.

Finally, PCB production is a thorough and exact procedure, needing a high level of know-how and quality assurance. Each action, from layout to last examination, plays a vital function in making sure the PCB does as meant in its final application. As technology advancements, the PCB manufacturing procedure continues to develop, accommodating a lot more intricate designs and cutting-edge products.