Ensuring Reliable Power Supply A Comprehensive Guide to Scheduled Maintenance for Diesel Generators

Introduction

Diesel generators play a crucial role in providing backup power during emergencies and ensuring uninterrupted electricity supply in various applications such as hospitals, data centers, industrial facilities, and residential buildings. To maintain the reliability and performance of diesel generators, scheduled maintenance is essential. This article will delve into the importance of scheduled maintenance for diesel generators, the key components that need regular attention, recommended maintenance tasks, and best practices to ensure the optimal performance and longevity of diesel generators.

Importance of Scheduled Maintenance for Diesel Generators

Scheduled maintenance is critical for diesel generators to ensure they operate efficiently and reliably when called upon to provide backup power. Neglecting regular maintenance can lead to a range of issues, including decreased performance, higher fuel consumption, increased emissions, and even complete generator failure during critical situations. By following a structured maintenance schedule, operators can detect and address potential problems early, preventing costly repairs and downtime.

Key Components Requiring Regular Maintenance

1. Engine

The engine is the heart of a diesel generator and requires regular maintenance to ensure proper functioning. Key maintenance tasks for the engine include oil and filter changes, fuel system inspection, coolant level checks, and air filter replacement. Regularly monitoring engine performance, such as temperature and pressure readings, can help identify issues before they escalate.

2. Fuel System

The fuel system is another critical component of a diesel generator that needs attention during scheduled maintenance. Fuel filters should be replaced regularly to prevent contaminants from entering the engine. Additionally, fuel lines and injectors should be inspected for leaks or blockages that can affect fuel delivery and engine performance.

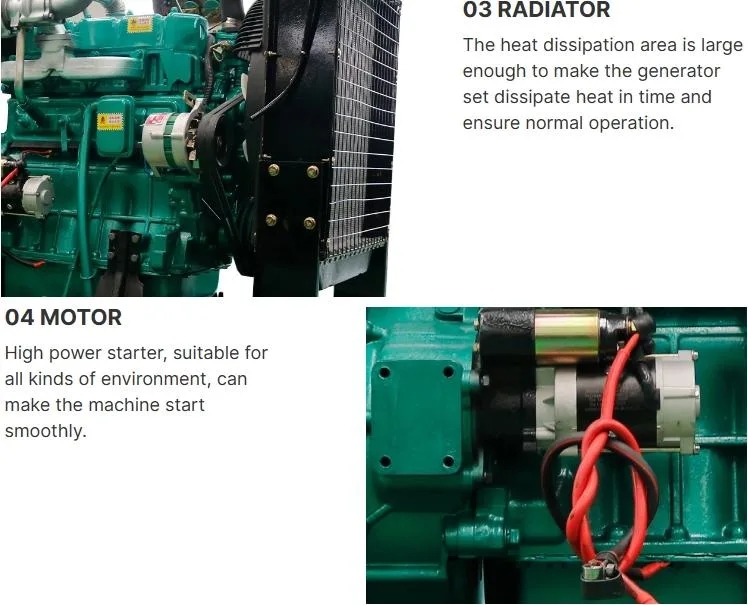

3. Cooling 400kw generator cooling system plays a vital role in regulating the temperature of the diesel generator to prevent overheating. Regular maintenance tasks for the cooling system include checking coolant levels, inspecting hoses and connections for leaks, and cleaning the radiator to ensure proper heat dissipation. Failure to maintain the cooling system can lead to engine overheating and potential damage.

4. Electrical System

The electrical system of a diesel generator, including the alternator, voltage regulator, and control panel, should be inspected regularly to ensure proper operation. Loose connections, damaged wiring, and faulty components can lead to electrical issues that impact the generator's performance. Scheduled maintenance should include testing the electrical system under load conditions to verify its reliability.

Recommended Maintenance Tasks for Diesel Generators

1. Oil and Filter Changes

Regular oil changes are essential to keep the engine lubricated and protect against wear and corrosion. The frequency of oil changes will depend on the generator's usage and operating conditions. Along with oil changes, it is crucial to replace the oil filter to remove contaminants and maintain oil quality.

2. Fuel Filter Replacement

Fuel filters should be replaced at recommended intervals to prevent dirt, water, and other impurities from reaching the engine. Clogged fuel filters can restrict fuel flow and lead to engine stalling or reduced performance. Regularly inspecting and replacing fuel filters is vital for the proper operation of the diesel generator.

3. Air Filter Replacement

Clean air is essential for the combustion process in a diesel engine. Air filters prevent dust, dirt, and other particles from entering the engine and causing damage. Regularly inspecting and replacing air filters will ensure optimal engine performance and fuel efficiency.

4. Cooling System Maintenance

Maintaining the cooling system is crucial to prevent overheating and engine damage. Regularly check coolant levels, inspect hoses and connections for leaks, and clean the radiator to remove debris. It is also important to monitor coolant quality and replace it at recommended intervals to prevent corrosion and buildup.

5. Battery Inspection and Testing

The battery is essential for starting the diesel generator and providing power to the control panel. Regularly inspect the battery for signs of corrosion, leaks, or damage. Test the battery's voltage and capacity to ensure it can meet the generator's starting requirements. Replace the battery if it shows signs of deterioration.

Best Practices for Diesel Generator Maintenance

1. Create a Maintenance Schedule

Developing a comprehensive maintenance schedule that includes all recommended tasks and intervals is essential for ensuring the proper upkeep of the diesel generator. Assign responsibilities to designated personnel and keep detailed records of maintenance activities, including dates, tasks performed, and any issues identified.

2. Conduct Regular Inspections

In addition to scheduled maintenance tasks, conducting regular visual inspections of the diesel generator can help identify potential problems early. Look for signs of leaks, corrosion, loose connections, and abnormal noises during inspections. Address any issues promptly to prevent further damage.

3. Follow Manufacturer Recommendations

Follow the manufacturer's guidelines and recommendations for maintenance intervals, procedures, and replacement parts. Using genuine parts and following prescribed maintenance practices will help ensure the optimal performance and longevity of the diesel generator.

4. Keep Detailed Records

Maintaining detailed records of all maintenance activities, repairs, and inspections is essential for tracking the history of the diesel generator. These records can help identify trends, track performance metrics, and provide valuable information for troubleshooting and decision-making.

5. Train Personnel

Ensure that personnel responsible for diesel generator maintenance are properly trained and equipped to perform maintenance tasks safely and effectively. Training programs should cover maintenance procedures, safety protocols, and emergency response measures to handle unexpected situations.

Conclusion

Scheduled maintenance is essential for ensuring the reliable operation of diesel generators and preventing costly downtime. By following a structured maintenance schedule, inspecting key components regularly, and performing recommended maintenance tasks, operators can optimize the performance and longevity of diesel generators. Adhering to best practices, such as creating a maintenance schedule, following manufacturer recommendations, keeping detailed records, and training personnel, will help maintain the reliability of diesel generators and ensure uninterrupted power supply when needed. Prioritizing scheduled maintenance is an investment in the longevity and performance of diesel generators, ultimately enhancing the resilience of critical infrastructure and applications that rely on backup power.