Decoding the Economic Equation of Rapid Prototyping: Balancing Expenses and Benefits

In the dynamic world of item growth, rapid prototyping has actually ended up being a crucial device, using rate and flexibility that typical approaches can not match. Nevertheless, understanding the financial effects of taking on rapid prototyping is important for companies. This detailed evaluation looks into the cost ramifications and economic advantages of using rapid prototyping, providing insights right into exactly how it reshapes the economic landscape of product advancement.

Comprehending the Price Structure of Rapid Prototyping

Initial Investment: The first price of acquiring rapid prototyping tools, specifically 3D printers, can be substantial. Nevertheless, Discover More is often balanced out by long-term financial savings in other locations of product development.

Material Prices: The price of materials used in rapid prototyping varies widely, depending on the type (plastics, steels, materials) and the volume of products utilized. Advanced products may raise expenses but provide exceptional model top quality.

Functional Expenditures: Operating and keeping rapid prototyping tools includes functional costs, consisting of energy usage, maintenance, and labor prices.

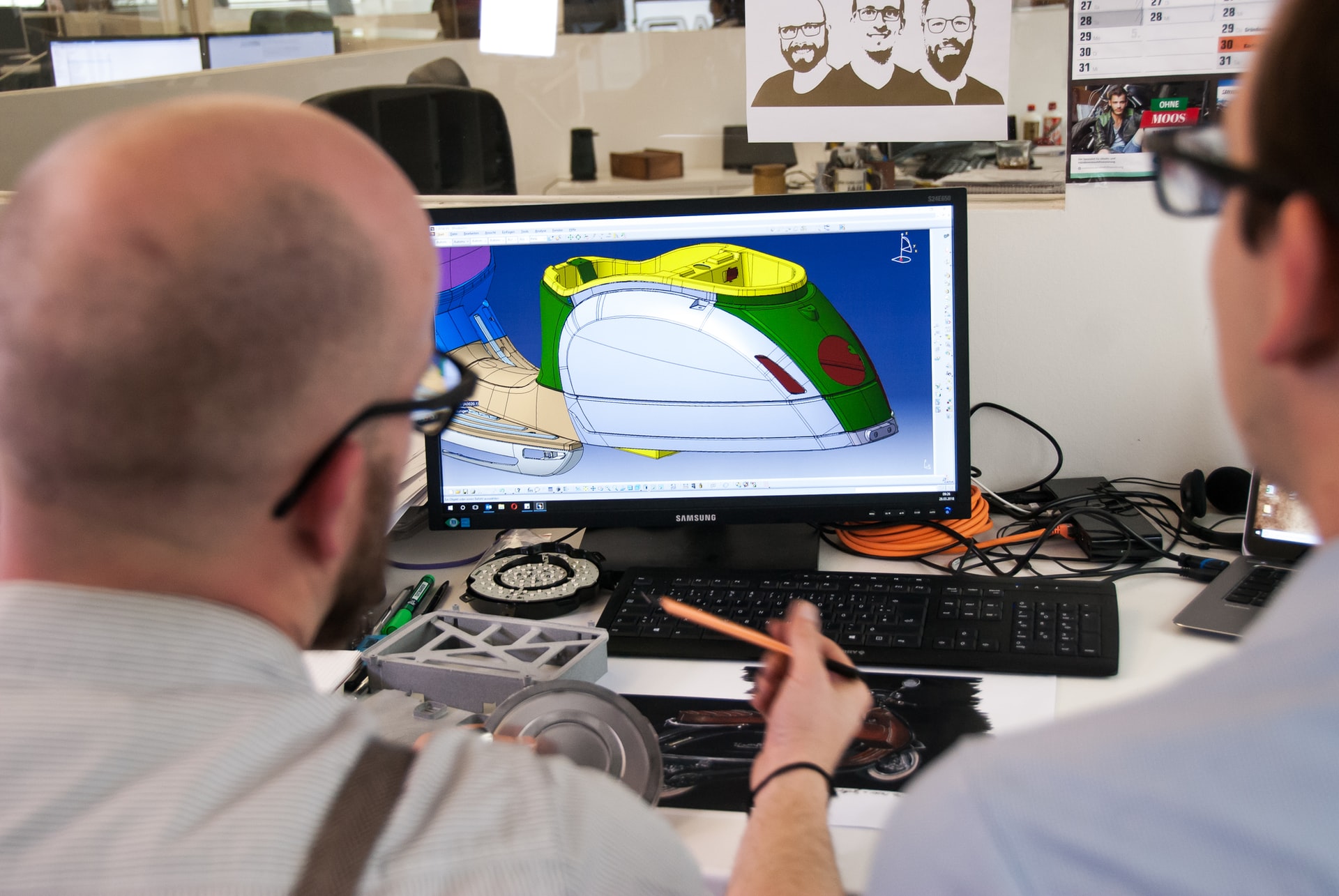

Layout and Evaluating Costs: While rapid prototyping decreases the need for expensive tooling, costs are still incurred in the design phase, particularly in CAD modeling and prototype testing.

Financial Benefits of Rapid Prototyping

Minimized Time to Market: Rapid prototyping dramatically shortens the item advancement cycle, allowing services to bring products to market quicker, which can be a critical competitive advantage.

Price Savings in Style and Advancement: By allowing early detection of design imperfections and reducing the requirement for numerous iterations, rapid prototyping can result in considerable price financial savings in the design and development phase.

Adaptability and Modification: Rapid prototyping allows for greater flexibility in product layout and the capability to conveniently personalize products, which can result in new market opportunities and greater earnings margins.

Lowered Waste and Stock Expenses: Additive manufacturing techniques used in rapid prototyping produce less waste compared to subtractive techniques, resulting in cost financial savings in material use. It additionally lowers the requirement for holding huge stocks of components.

Stabilizing Expense and Value in Rapid Prototyping

Cost-Effectiveness Analysis: Services should carry out a detailed cost-effectiveness evaluation to recognize the trade-offs between the first financial investment in rapid prototyping innovation and the long-lasting cost savings and benefits.

Scaling Production: While rapid prototyping is suitable for small-scale manufacturing and prototypes, scaling to mass production may require additional considerations in regards to expense and efficiency.

Incorporating with Typical Methods: In a lot of cases, rapid prototyping is most effective when used combined with conventional manufacturing methods, stabilizing the benefits of rate and versatility with the economic climates of scale of traditional manufacturing.

The Future Economic Landscape of Rapid Prototyping

Technological Improvements: As rapid prototyping technologies remain to advance, expenses are expected to decrease, making it extra easily accessible to a more comprehensive series of businesses.

Bigger Sector Adoption: With broader fostering across industries, the economic benefits of rapid prototyping are most likely to expand, driving technology and performance in product advancement.

Sustainability and Economic Influence: The step in the direction of even more lasting manufacturing methods, including making use of environment-friendly materials in rapid prototyping, can have favorable financial implications, lining up price financial savings with ecological obligation.

Verdict

Rapid prototyping provides a complex but encouraging financial proposition in product growth. While it includes upfront costs, the long-term economic advantages - from decreased advancement times and costs to increased market responsiveness - make it an invaluable asset in contemporary manufacturing. As businesses remain to navigate the cost-benefit evaluation of rapid prototyping, its function in driving advancement, performance, and success in product growth is set to expand, reshaping the financial landscape of manufacturing and design.