From Lumber Workshops to Workshops: The Versatility of Bolts and Bolts

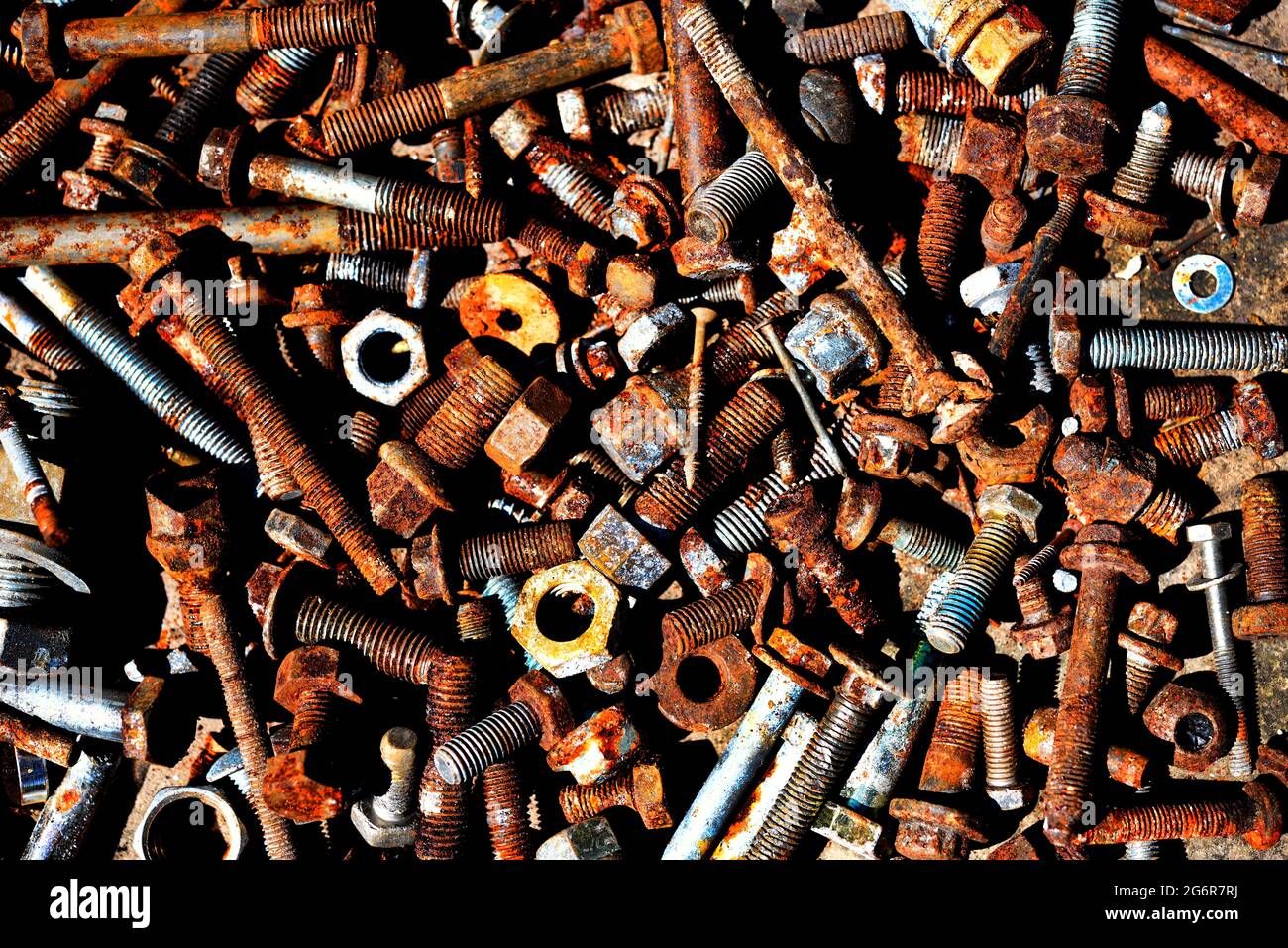

Bolts and bolts are often seen as the unsung heroes of building and repair, quietly keeping everything together behind the scenes. From the frame of a robust edifice to the intricate systems of your beloved vehicle marvel, these fasteners play a crucial role in numerous applications. Despite their simplicity, the world of nuts and nuts is rich with variety, each type crafted for distinct applications and environments. Understanding the different kinds available, their unique functions, and when to use them can empower you to handle a broad spectrum of projects with confidence.

In this complete guide, we will delve into the intriguing realm of bolts and nuts, covering everything from the most common types of fasteners to the unique hardware that can determine the success of a project. Whether you are starting a DIY home improvement project, working on industrial construction, or conducting automotive repairs, knowing how to select the appropriate fastener can significantly affect the durability and safety of your project. By the end of this article, you will be armed with the understanding to select the most suitable nut and bolt for any task at hand.

Understanding Bolts and Nuts

Bolts and nuts are crucial fasteners utilized in numerous settings, providing robustness and safety in areas ranging from construction tasks to car repairs. Bolts are a screwed fastener having a head usually secured using a wrench, whereas a nut can be a hexagonal piece which connects to the bolt’s threads to hold materials in place. Collectively, they form a strong mechanical bond capable of enduring considerable stress, which makes them essential to both professional and DIY projects.

The versatility of nuts and bolts derives from the many varieties available, each designed for specific uses. As an example, common bolts are ideal for common tasks, lag bolts are perfect for intensive building, and carriage bolts are frequently used in woodwork. Comprehending the purpose of these fasteners aids in choosing the appropriate fastener for your project, guaranteeing strength and stability and durability in your crafting or repair tasks.

The types of threads are another crucial aspect of bolts and nuts, impacting their efficiency. Coarse threads give increased hold on softer materials, whereas fine threads provide superior grip in compact areas. Knowing these distinctions, along with the difference between metric and imperial measurements, is vital in the selection of fasteners. As tasks range from complex vehicle fixes as well as strong construction, grasping the basics of nuts and bolts enables improved choices and effective results.

spintax

### Types and Applications

Nuts and bolts come in a variety of forms, dimensions, and materials, each crafted for specific applications. For instance, hex bolts are prevalent in general construction due to their durability and flexibility. These versatile fasteners are compatible with conventional tools, making setup and removals easy. Carriage fasteners, on the other hand, are perfect for wooden structures, featuring a curved top that stops tearing wood, making them suitable for outdoor furniture or deck builds.

In the realm of heavy-duty building, selecting the appropriate bolts is crucial. Lag bolts, known for their strong grip in wood, are often used in fastening beams or heavy furniture. Meanwhile, steel bolts, used in steel constructions, offer superior tensile strength and are essential in structures. Understanding which type of bolt is suited for your project can vastly enhance both durability and safety.

When it comes to fastener nuts, the choices are also diverse. Lock nuts are designed to prevent unthreading under vibration, making them ideal for vehicle uses where movement is frequent. Flange nuts provide a large bearing surface to spread the load more uniformly, ideal for fragile materials. Determining which type of nut to pair with your selected bolt is essential for achieving the desired level of security and performance in any construction.

Materials and Standards

The substances used in fasteners and bolts play a critical role in determining their durability, endurance, and fitness for multiple uses. Metal is the predominant material, valued for its high tensile strength and flexibility. Within these details of metal, there are different grades, such as stainless steel, which offers superior corrosion resistance, and low-carbon steel, known for its affordability and strength. For specialized uses, materials like brass and titanium are also available, each offering distinct properties such as lightweight design or enhanced resistance to corrosion and wear.

Understanding specifications is essential for choosing the right fastener. Bolt grades indicate the strength and quality of the linking element, with a higher grade typically signifying superior performance. For example, a class 8 bolt is more robust than a class 5 bolt and is often suggested for heavy-duty applications. Similarly, nut specifications should correspond with the bolt grade to ensure a secure fit. Types of threads—粗, 精, and 公制—must also match between fasteners and bolts to ensure correct fitting, which can significantly impact the overall integrity of the assembly.

Finishes can further enhance the performance of fasteners and screws. Zinc-plated fasteners are common and provide fundamental corrosion resistance, while galvanized options offer more robust protection for external use. Specialty coatings, such as those found on security fasteners, add tamper resistance, while nylon lock nuts utilize a unique design to prevent loosening under vibration. When choosing fasteners, consider the composition and standard to ensure maximum performance for your particular project requirements.