Comparing Different Types of PV Cables for Solar Energy Systems

Introduction

Photovoltaic (PV) systems have become increasingly popular as a sustainable and renewable energy source. These systems rely on solar panels to convert sunlight into electricity, which can be used to power homes, businesses, and various other applications. One crucial component of a PV system is the cables that connect the solar panels to the inverters and other components. Choosing the right type of cable is essential for ensuring the efficiency, safety, and longevity of the system. In this article, we will compare and contrast different types of PV cables commonly used in solar energy systems.

Types of PV Cables

1. Photovoltaic Wire (PV Wire)

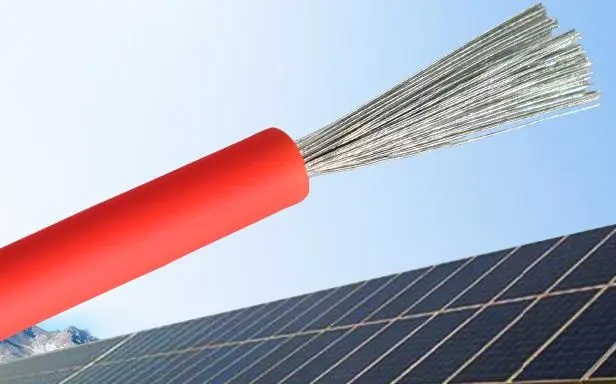

PV wire is a type of cable specifically designed for use in photovoltaic systems. It is typically made of copper conductors with thick insulation to protect against environmental factors such as sunlight, moisture, and temperature fluctuations. PV wire is available in different gauges and can be used for both residential and commercial PV installations. One of the key advantages of PV wire is its flexibility, which makes it easy to install and route around corners and obstacles.

2. Photovoltaic Cable (PV Cable)

PV cable is similar to PV wire but is typically larger in diameter and has a higher current-carrying capacity. This type of cable is commonly used for larger solar installations where higher power output is required. PV cables are often jacketed with materials such as cross-linked polyethylene (XLPE) or ethylene propylene diene monomer (EPDM) to provide additional protection against UV radiation and moisture. PV cables are available in various sizes and configurations to suit different system requirements.

3. USE-2 Cable

Underground Service Entrance (USE)-2 cable is a type of cable that is commonly used for outdoor and underground PV installations. It is designed to withstand exposure to sunlight, moisture, and extreme temperatures. USE-2 cable is typically rated for direct burial in soil without the need for conduit, making it a popular choice for ground-mounted solar arrays. This type of cable is often dual-rated as both PV wire and USE-2 cable, providing flexibility in installation options.

4. MC4 Cable Assemblies

MC4 cable assemblies are a type of pre-assembled cable set commonly used in PV systems. These assemblies consist of MC4 connectors on both ends of the cable, allowing for quick and easy connections between solar panels, inverters, and other components. MC4 connectors are industry-standard connectors that are designed to be weatherproof and durable. MC4 cable assemblies come in various lengths and configurations to suit different system layouts and requirements.

5. Tray Cable

Tray cable is a type of cable that is commonly used in industrial and commercial PV installations. It is designed for use in cable trays, conduits, and other exposed applications where mechanical protection is required. Tray cable is often jacketed with materials such as thermoplastic elastomer (TPE) or polyvinyl chloride (PVC) to provide additional protection against oil, chemicals, and abrasion. Tray cable is available in various configurations, including shielded and armored versions for added protection.

Comparison of PV Cable Types

When choosing the right type of cable for a PV system, several factors need to be considered, including cost, efficiency, durability, and safety. Let's compare the different types of PV cables based on these factors:

1. Cost

PV wire is generally the most cost-effective option for small to medium-sized PV systems. It is readily available and easy to install, making it a popular choice for residential installations. PV cable and USE-2 cable are slightly more expensive but offer higher current-carrying capacity and better protection against environmental factors. MC4 cable assemblies are convenient but can be more costly due to the pre-assembled connectors. Tray cable is the most expensive option but provides superior mechanical protection and durability.

2. Efficiency

The efficiency of a PV cable is determined by its electrical conductivity and insulation properties. Copper conductors are the most common choice for PV cables due to their high conductivity, which minimizes power loss during transmission. Insulation materials such as XLPE and EPDM provide excellent protection against temperature variations and UV radiation, ensuring optimal performance of the system. MC4 connectors are known for their low contact resistance, which helps maintain high efficiency in the connections.

3. Durability

Durability is a critical factor in the selection of PV cables, as they are exposed to harsh environmental conditions such as sunlight, moisture, and temperature extremes. PV wire, PV cable, and USE-2 cable are all designed to withstand these conditions and have a long service life. The jacketing materials used in these cables provide protection against UV radiation, abrasion, and chemical exposure. MC4 cable assemblies are also designed to be weatherproof and durable, ensuring reliable connections in outdoor environments. Tray cable offers the highest level of durability with additional protection against mechanical damage and environmental hazards.

4. Safety

Safety is paramount in PV systems to prevent electrical hazards and ensure the protection of people and property. All PV cables must meet industry standards for electrical insulation, flame resistance, and environmental protection. PV wire, PV cable, and USE-2 cable are rated for use in PV systems and are designed to meet these safety requirements. MC4 connectors are specifically designed for outdoor use and are tested for reliability and weather resistance. Tray cable is suitable for applications where additional mechanical protection and safety are required.

Conclusion

Choosing the right type of cable for a PV system is essential for ensuring the efficiency, safety, and longevity of the system. Each type of PV cable offers unique advantages and is suitable for different applications based on cost, efficiency, durability, and safety requirements. insulated sheathed power cable is a cost-effective and flexible option for residential installations, while PV cable and USE-2 cable are ideal for larger systems that require higher current-carrying capacity and environmental protection. MC4 cable assemblies provide a convenient solution for quick and reliable connections, while tray cable offers the highest level of durability and mechanical protection. By considering these factors and comparing the different types of PV cables, solar installers and system designers can select the most suitable cable for their specific needs and requirements.