The Ultimate Guide to Portable Equipment Power Cables Essential Information Types and Best Practices

Introduction

Portable equipment power cables play a crucial role in powering a wide range of devices and tools in various settings, from construction sites to outdoor events. These cables are designed to provide a reliable source of power for portable equipment, ensuring that they operate efficiently and safely. In this comprehensive guide, we will explore everything you need to know about portable equipment power cables, including their importance, types, best practices for use, and maintenance tips.

Importance of Portable Equipment Power Cables

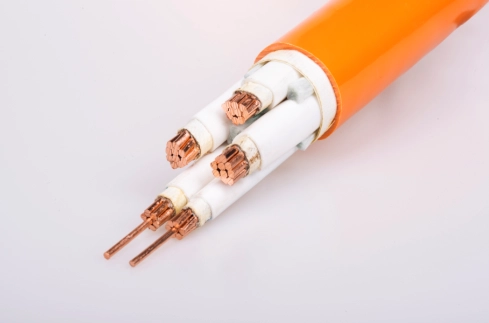

Portable equipment power cables are essential for providing power to a wide range of devices and tools that are used in different industries and applications. These cables are designed to deliver electricity from a power source to portable equipment, allowing them to function properly. Without Mineral Insulated Cable , portable equipment may not work efficiently or safely, leading to potential hazards and downtime.

One of the key advantages of portable equipment power cables is their flexibility and durability. These cables are designed to withstand the rigors of daily use in demanding environments, making them ideal for outdoor applications and rough conditions. Additionally, portable equipment power cables are available in various lengths and configurations to suit different types of equipment and power requirements.

Types of Portable Equipment Power Cables

There are several types of portable equipment power cables available on the market, each designed for specific applications and environments. The most common types of portable equipment power cables include:

1. Extension Cords: Extension cords are a basic type of portable equipment power cable that are used to extend the reach of power sources to equipment that is located far away. These cords are typically lightweight and flexible, making them easy to transport and handle.

2. SOOW Cables: SOOW cables are heavy-duty portable equipment power cables that are designed for use in rugged environments. These cables are oil-resistant, water-resistant, and resistant to abrasion, making them ideal for outdoor applications and industrial settings.

3. SJOW Cables: SJOW cables are similar to SOOW cables but are designed for general-purpose use. These cables are flexible and durable, making them suitable for a wide range of portable equipment applications.

4. Welding Cables: Welding cables are specialized portable equipment power cables that are designed for use in welding applications. These cables are highly flexible and heat-resistant, making them ideal for carrying high currents in welding environments.

5. Generator Cables: Generator cables are used to connect portable generators to equipment that requires power. These cables are designed to handle high currents and provide a reliable power supply to portable equipment.

Best Practices for Using Portable Equipment Power Cables

To ensure the safe and efficient operation of portable equipment power cables, it is important to follow best practices for their use. Some key best practices for using portable equipment power cables include:

1. Inspect Cables Regularly: Before each use, inspect portable equipment power cables for any signs of damage, such as cuts, frays, or exposed wires. Do not use damaged cables, as they can pose a safety hazard.

2. Choose the Right Cable for the Job: Select the appropriate type and length of portable equipment power cable for the specific equipment and power requirements. Using the wrong cable can lead to inefficiencies and potential hazards.

3. Avoid Overloading Cables: Do not overload portable equipment power cables by connecting too many devices or equipment to a single power source. Overloading can cause overheating and damage to the cables.

4. Keep Cables Clean and Dry: Ensure that portable equipment power cables are kept clean and dry to prevent moisture and dirt from damaging the cables. Store cables in a dry and secure location when not in use.

5. Use Cable Protectors: When using portable equipment power cables in high-traffic areas, consider using cable protectors to prevent tripping hazards and protect the cables from damage.

Maintenance Tips for Portable Equipment Power Cables

Proper maintenance of portable equipment power cables is essential to ensure their longevity and performance. Some maintenance tips for portable equipment power cables include:

1. Clean Cables Regularly: Wipe down portable equipment power cables with a clean, damp cloth to remove dirt and debris. Avoid using harsh chemicals or solvents that can damage the cables.

2. Store Cables Properly: When not in use, coil portable equipment power cables neatly and store them in a dry and secure location. Avoid twisting or bending the cables excessively, as this can cause damage.

3. Repair Damaged Cables: If you notice any damage to portable equipment power cables, such as cuts or frays, repair them immediately using electrical tape or heat shrink tubing. Do not use damaged cables.

4. Avoid Extreme Temperatures: Do not expose portable equipment power cables to extreme temperatures, as this can degrade the cable insulation and affect their performance. Store cables in a moderate temperature environment.

Conclusion

Portable equipment power cables are essential components for powering a wide range of devices and tools in various industries and applications. By understanding the importance of portable equipment power cables, knowing the different types available, following best practices for their use, and implementing proper maintenance techniques, you can ensure the safe and efficient operation of your portable equipment. Remember to regularly inspect, clean, and store your portable equipment power cables to prolong their lifespan and maintain their performance. With the right knowledge and care, portable equipment power cables can continue to power your equipment reliably for years to come.