Lots Examining Protocols for Office Helical Pile Installments

Helical heaps have actually earned their location in industrial job considering that they incorporate predictable habits along with prompt installation. You obtain immediate ability analyses from twist correlation, and also you can set up in tight urban web sites along with low spoils. Still, every experienced installer and also developer knows the same fact: the genuine proof of a deeper groundwork resides in the tons exam. On a health center enhancement in clay-based, on a storehouse slab where negotiation endurances are actually thrifty, or even on a maintaining wall surface using helical tieback anchors, you simply obtain peace of mind when the heaps or supports reveal their efficiency under measured load.

This article pays attention to lots testing methods adapted to commercial helical pile installation as well as helical tieback anchor job. It likewise touches the edges where micropiles, protection stacks, and other deep foundation repair procedures meet the same need for confirmation. The goal is actually practical advice: what to examine, exactly how to test it, and also how to decipher the end results without acquiring deceived through noise in the records or impractical expectations.

Why we evaluate, also when torque appears good

Helical stacks possess an influential purchases pitch: set up along with a calibrated drive head, display torque, and associate to capability. In clean sands and sands, the correlation usually stores within 10 to twenty percent, which is great for production. Commercial helical pile installation, though, hardly ever happens in schoolbook strata. Our team find layered fills, varved clay-baseds, settled groundwater, and also energy hallways that have disrupted the soil over many years. Torque spikes are common, and gentle pockets can conceal in between tense horizons.

Load testing legitimizes three factors you may certainly not observe during setup. To begin with, the true bunch transmission mechanism at the helices as well as along bum rap. Second, creep actions gradually, which matters when a commercial foundation stabilization system should reside under a sensitive superstructure. Third, the structural functionality of the body itself: couplers, shafts, cement columns in hybrid devices, as well as caps.

I recall a retail slab-on-grade retrofit where torque recommended 50 kips per stack. The load examination revealed satisfactory supreme capacity near that worth, but the movement at service weight was very big for the slab. The solution included making use of bigger top areas along with much deeper coils to lower deflection, not simply going after much higher torque. helical piering systems Without a load exam, our experts will have met the letter of ability as well as still disappointed the manager along with slab curling as well as partition cracking.

Choosing a test style that accommodates the project

Static central compression as well as pressure examinations are actually the backbone for helical piles and helical anchors. Lateral examinations are much less typical but important for signage, tower bases, and also some cover supports. For tieback anchors, verification and also performance exams under tension determine the plan. Dynamic examinations turn up much more with driven piles than with helicals, and also while you can easily work quick tons examinations on micropiles, helical units respond best to continual stationary packing considering that variation and also creep under consistent lots are actually the essential criteria.

For commercial resistance pile installation and also micropile installation, static examinations observe similar logic, however the machinery varies. Micropiles usually invite pressure evaluates to split up connect region coming from ground anchor zone. Protection stacks, particularly press boat docks used in structural foundation repair, profit from on-jack gauges that looking glass service conditions throughout underpinning.

When owners seek value design, the appeal is actually to reduce lots testing initially. That is actually a misleading economic situation. A solitary effectively implemented functionality examination on a propitiatory helical pile, plus evidence exams on a percentage of production units, usually lowers the overall risk and also might also permit reasonable reductions in product or even deepness that conserve greater than the exam costs.

Standards, standards, as well as useful thresholds

Most business requirements draw from ICC-ES acceptance requirements, ASTM specifications, and also geotechnical recommendations. For helical piles as well as helical anchors, the usual references include ICC-ES AC358 and ASTM D1143 for compression, ASTM D3689 for stress, and also ASTM D3966 for side. Tieback anchors frequently adhere to PTI recommendations for testing and lock-off methods. These documentations set out action launching, hold opportunities, and recognition standards for action and also creep.

Serviceability restrictions are as vital as supreme capacity. For commercial foundation repair as well as brand-new building, company lots action limits might range coming from 0.25 to 0.5 inches at full design tons, sometimes tighter for slab-supported devices. Creep requirements at the ultimate grip action commonly restrain movement to a handful of thousandths of an in per min over a specified period, often 10 mins. The specific amounts acquire tuned to project needs, ground kind, and danger tolerance.

One efficient general rule: if you are mounting in smooth clay-baseds along with liquidity marks near 0.7 or greater, insist on longer grip durations. Clay-based needs to have opportunity to present its own colors. Sands respond swiftly, however can show relaxation. Silts partake the uncertain center. Your procedure needs to mirror the dirt's time dependence or even you may pass an exam that later comes to be a resolution claim.

Equipment that always keeps information honest

Load testing rigs are just like their referrals. The response structure have to be actually stiff as well as anchored in a way that performs certainly not infect the measurement. For squeezing tests on helical piles, this often means an exam shaft connected to neighboring reaction heaps inserted deep sufficient to steer clear of impact coming from the test stack. In strain, response frames get onto supports or deadmen. For helical tieback anchor screening, the response is actually usually the wall surface itself or a steel strongback along with appropriate spreader beams.

Digital bunch cells and also stroke transducers have ended up being the rule in business job, certainly not just nice-to-have. A 100-ton hollow ram coupled with a calibrated pressure transducer is actually great if you have a clean calibration arc and also verify every gauge prior to the test series. Direct variation transducers positioned individually of the port, reviewing versus a taken care of endorsement outside the reaction area, do away with the inaccurate motion that originates from frame curvature or even jack seats. If your information acquisition unit captures tons and also variation at 1 Hz or faster, trending and creep assessment come to be straightforward.

For micropiles and also resistance piles, you may additionally add dial gauges pinned to a small endorsement beam to cross-check the digital equipments. Verboseness matters when a little reading can sway recognition. On a court house underpinning with resistance heaps, we discovered an arched jack port offering higher stress analyses. The dial gauges said to the genuine tale. That little cross-check saved a heap cut-off as well as re-drive.

Establishing a test source that makes confidence

On huge internet sites, dirts vary. Assessing a single helical turn in the superficial stuffing at the n. side tells you little concerning the deeper alluvium near the river. The exam matrix needs to have to spread all over the internet site, line up along with the geotechnical profile page, and also stand for each concept version: stack lead setups, helix sizes, shaft dimensions, and also embedment midsts. When commercial helical pile installation assists both pillar tons and piece bunches, exam both scenarios. For helical tieback anchor service a stepped preserving wall structure, test the upper and lower benches considering that additional charge and also ground density will differ.

An usual design pairs one or two performance tests, usually to 200 percent of design load, along with evidence screening on 5 to 10 percent of manufacturing units to 133 percent. Ventures with high effects or blended grounds might press efficiency exams to 250 percent and also verification to 150 percent. Tieback anchors normally receive evidence checked to a lock-off approach, at that point packed in steps to 120 to 133 per-cent, along with creep evaluated on top grip. If action or creep exceeds approval limitations, check out and readjust the design prior to waging production.

On a coordinations stockroom outside Des Moines, our team functioned three execution tests on helical piles along with 10-12-14 inch helices. The southern exam hit thick sand early, and the capability went beyond the torque estimate through virtually 30 percent. The northerly area sat over a silty clay coating and matched torque connection within 5 percent. The center region looked average yet showed obvious creep at 150 percent of design. Our experts tightened up solution activity criteria there and defined much longer helices to reach a reduced pressure perspective, which eventually kept slab joints strict under forklift traffic.

Step running that uncovers actual behavior

Static tons exams have to stabilize effectiveness along with analysis worth. Stepping as well promptly hides time-dependent motions and also can misdiagnose the capability. A sound protocol for squeezing could pack the helical pile to 25 per-cent, half, 75 per-cent, 100 percent, then 133 percent, with 5 to 10 min keeps at each measure as well as longer stores at the top. After getting to the maximum test tons, unload symphonious, securing briefly to tape-record elastic rehabilitation. If the requirements asks for a failure exam, continue loading in much smaller increases until the motion increases without lots rise, or even up until you reach the safe limitations of the frame.

For tension, the measures and also carries are actually identical. Take note of first seating or even bedding-in motion as the hookups as well as cement, if any kind of, occupy resistances. Helical tieback anchors generally adhere to a verification examination cycle: seat at a nominal load, pattern around the maximum test tons with described holds, at that point go back to the lock-off tons. Creep is actually gauged just on top bunch on a fresh application, certainly not throughout cycles, to prevent perplexing plastic prepared with time-dependent deformation.

The keep opportunity controversy appears on virtually every task. Some really want 5 minute keeps for velocity, others require 10 or even 60 mins in clays. My technique is actually to straighten along with the ground. Sands and also gravels, five minute hosts at more advanced steps and 10 to 15 moments at the max are actually often enough. In fat clay-baseds, double those times. If your displacement arc flattens, you may validate going on. If it keeps slipping at a quantifiable fee, carry out not dismiss the trend.

Reading the contours without fooling yourself

A great bunch examination record tells a story. The payload versus movement story shows stiffness modifications as coils engage different levels, and the discharge course hints at shaft elasticity versus ground collection. In a well-maintained result, the 1st aspect of the curve is high, then it relaxes as activated protection creates, as well as eventually it either stage toward failure or even remains steady within the solution selection. Creep plots different flexible activity from time-dependent ground response.

Look for subtle ideas. If the variation dives at reduced tons, check for seating or even structure slippage. If creep at 133 percent of layout declines coming from 0.005 inches per minute to 0.001 ins every moment over the hold, that is well-balanced consolidation. If it remains at or even over 0.01 inches every moment, specifically in clay, you are actually moving toward an use limit even though ultimate ability is actually certainly not gotten to. Tiebacks along with extreme rebound on dump may have bed linen slop near the bearing plate as opposed to concerns in the ground. Tidy up the bearing surface areas as well as retest before transforming the design.

Micropiles and resistance piles tell identical tales along with a little various signatures. Micropiles with a lengthy bond duration show a continuous stiffness rise as even more of the grout-rock interface mobilizes. Protection heaps driven for deep foundation repair present load-displacement curves controlled by friction along bum rap and also often display snap-back on offload if the heap secures in to a stiffer level at depth. In all instances, consider exactly how the tons transfers and whether the noticed motion matches the device you expect.

The link between setup information and exam outcomes

Installers frequently live by torque charts, as well as once and for all main reason. Helical twist to ability connections, adjusted due to the details coil geometry and also shaft style, generate a fast price quote of best protection. An oversight I observe is actually managing torque readings as scripture across combined profile pages. If the top section sits in tight sand yet the top helix experiences in loose filler, you can easily reach target torque while leaving behind helical pile foundations the top bearing element immature, which hurts hardness and enhances settlement deal under solution tons. A load examination are going to expose this in the early component of the curve.

Track twist every change, crowd stress, and rate of infiltration. A consistent twist growth along with consistent penetration suggest regular soil. Spikes with stalls propose cobbles or even debris. When these trademarks associate with the examination place, you obtain situation for the movement behavior. On a commercial helical pile installation below a chiller pad, our team observed wonderful twist at shallow deepness. The load test felt smooth at company. The remedy was turning deeper to seat the bottom helix right into virgin ground, which stabilized the feedback and also cut the solution movement in half.

For commercial resistance pile installation, the analog is drive tension and stroke every press. For micropiles, it is cement take as well as tremie pressure throughout placement, plus connect duration as well as rock socket specifications. If the bunch examination says one point and your installment data point out another, investigate prior to you decide on a side.

Acceptance criteria that perform certainly not box you in

Rigid criteria typically cause excessive heap substitutes. Realistic recognition for a helical turn in squeezing may consist of a maximum internet movement at concept bunch, claim 0.5 inches, and a creep fee listed below a defined limit, like 0.01 inches in the last minute of a 10 min hold at 133 percent of style. Tieback anchors commonly demand lower than 0.04 ins of movement between one and also 10 minutes on top examination bunch, followed through dependable lock-off. These are actually instances, certainly not global worths. Projects with sensitive fronts or high-precision tools might ask for tighter amounts, while bulk storage space or racks may accept more.

Remember the business between best capacity and company performance. You can easily attain higher best ability along with tiny coils in heavy sand, yet still have a lot more flexible motion than the design yearns for. Much larger helices or deeper embedment boost connect with place as well as reduce variation at service. If an examination narrowly stops working a service motion standard yet shows low creep and higher utmost protection, a small redesign often addresses it without junking the stack type.

Tension screening and the distinctions of tieback anchors

Helical tieback anchors behave in different ways than vertical stacks. The load course goes through the anchor scalp, along the shaft, as well as into the coils seated in the passive area. The totally free length, whether a smooth extension or even a sleeved part, need to remain unbonded near the wall to permit lock-off without bunch loss. In the course of commercial helical tieback anchor installation, steady installation angle, coil spacing, as well as deepness behind the theoretical failure plane matter more than many appreciate.

A noise tieback evidence test patterns the bunch to the maximum test degree, secures for creep examination, and afterwards lessens to the lock-off lots while measuring elastic healing. Too much non-recoverable action suggest ground yielding or seating ahead. If the support slips unacceptably at the top bunch, you might be as well near to the breakdown airplane or even sitting in an unstable level. Extend the support or change the inclination to go after much better soil. Carry out certainly not rely on much higher twist alone to fix a geometry problem.

Keep an eye on wall structure interaction. I enjoyed a specialist criticize a tieback for creep when the strongback dispersed under lots, forging anchor movement. Independent recommendation beam of lights and also mindful setup avoid this. Really good testing protects both the installer and also the owner.

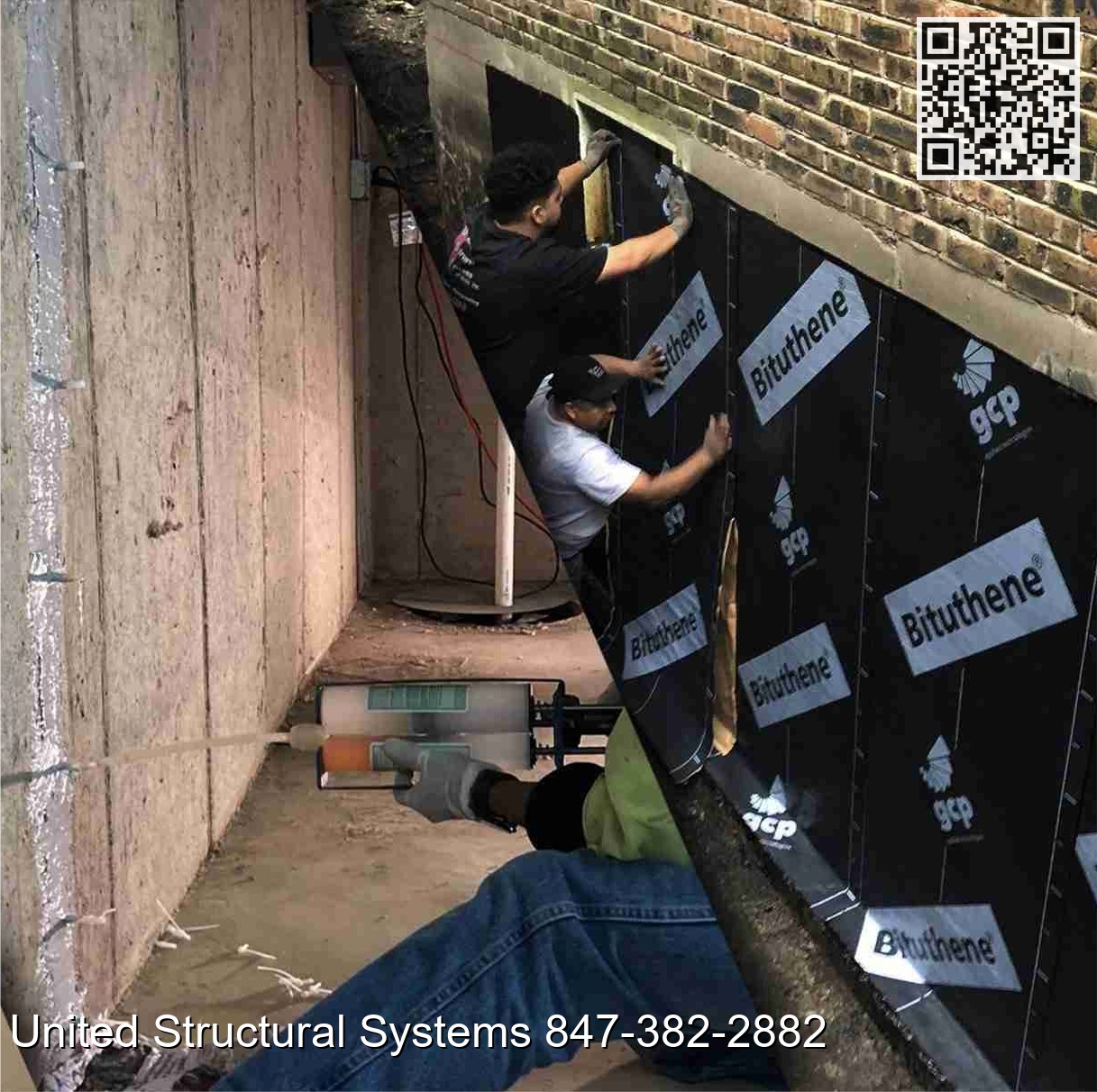

When tons testing complies with fixing work

Deep groundwork repair in office environments hardly ever gives the deluxe of open space. You are actually working in basements, under mechanical areas, or beside energetic electricals. For structural foundation repair that makes use of resistance stacks or helical piles, exam methods require to conform to limited allowances. Mobile reaction frames, shorter stroke ports, as well as segmented endorsement shafts maintain analyses clean. Foundation crack repair as well as piece stablizing typically link right into this system, because tons screening informs exactly how strongly you can raise or how much load to move just before the framework responds.

I have actually possessed excellence using a fly exam on two or 3 underpinning aspects before dedicating to a building-wide airlift. The examination informs you how the footing circulates bunch, just how the masonry or concrete will respond, and what assist increments the construct accepts. It can also uncover whether combined soil coatings under various bays need different heap types, for example making use of helical turn in sandier regions and micropiles where patches avoid helical advance.

Documentation that rises later

Commercial jobs live as well as perish by their reports. A tidy bunch examination plan includes gradation certificates, installation logs, examination procedures, uncooked and reduced data, secret plans, photographs of the create, and also area details detailing any sort of anomalies. When a third-party special examiner indications off, feature their file. If you differed the original planning, reveal the developer's commendation. These files guard your crew if issues occur and provide functions workers a guideline for potential modifications.

Many managers now anticipate digital deliverables that supply right into their possession monitoring bodies. Straightforward steps like naming data through pile ID as well as site, following one correlative unit, and adding a brief story for each and every examination minimize frustrations when somebody reviews the venture years later.

Lessons profited from the field

Load exams hardly get a 2nd odds. Make the effort to put individual recommendations as well as validate every gauge before the very first lots step. A tidy first test earns leave and also rates authorization for the rest. Torque is actually a resource, not a decision. Use it to steer installation, at that point depend on load screening to validate your assumptions. If the outcomes disagreement, find out why, certainly not who is right. Helical heaps excel in speed, but velocity draws faster ways. Always keep keep opportunities that match the ground. A 10 min pause is economical matched up to a flooring that settles an one-fourth in under occupancy. Cross-train your staff. The installer who knows how bunch exam contours ought to look will notice a concern during setup and also repair it prior to the examination reveals it. Accept that certainly not every pile will be actually perfect. Design an exam source as well as approval framework that flags outliers without stalling the whole job.

Where other bodies intersect

Commercial micro pile installation, commonly meant micropile installation, portions much of this particular screening DNA. Since micropiles count on grout-to-ground connection, their efficiency depends on development premium where you may certainly not find it. Fixed payload tests confirm both connection asset and also building capacity of the bar or covering. Tieback anchors, whether helical anchors or even grouted supports, demand the very same self-displined screening because their project is mostly regarding service activity command over time.

Resistance piles possess their spot in structural foundation repair, specifically when space is actually tight as well as grounds allow modern mounting to lots. Proof screening throughout setup, utilizing the property as response, affirms the tons each boat dock will definitely carry. Supplemental static exams on decided on piers, independent of the structure, support calibrate expectations and steer clear of overpromising to the owner.

When a job blends devices, like using helical piles for brand-new pillars and micropiles for highly crammed centers, always keep the testing process unique however collaborated. The proprietor wants one story concerning functionality, certainly not dueling charts.

Final ideas coming from a busy work trailer

When you operate commercial helical pile installation at scale, load testing ends up being much more than a checkbox. It is your feedback loop. It informs you whether a 12 in best helix need to be actually a 14, whether the embedment requires another 5 feet, whether the reaction frame is actually extremely soft, and also whether your workers knows the ground accurately. It divides a hassle-free handover coming from an irritating settlement deal grievance 6 months later.

The greatest programs loop three threads. The geotechnical file collections assumptions for dirt behavior. The installment logs capture true health conditions. The tons tests integrate the 2 and also write the performance section. Perform that, and the rest of the job adheres to: commercial foundation stabilization proceeds with assurance, structural foundation repair keeps its own line, and also even the meager foundation crack repair advantages given that the base remains steady.

I have actually been on websites where a solitary straightforward load examination changed the trajectory of the project right. Our experts added depth, altered a helix pattern, firmed up a spec, and also everybody rested much better. That is actually the result of a great process. It carries out not merely pass or even fail a pile. It shows you just how the ground is actually heading to treat your design for the next fifty years.

UNITED STRUCTURAL SYSTEMS OF ILLINOIS, INC

2124 Stonington Ave Hoffman Estates, IL 60169 847-382-2882 [email protected]> Mon-Fri 8:30am-5:00pm Sat-Sun By Appointment

Ask ChatGPT

Ask ChatGPT Ask Grok

Ask Grok Ask Perplexity

Ask Perplexity Ask Claude

Ask Claude Ask Google AI

Ask Google AI Ask You

Ask You