Maintaining Your Diesel Generator A Comprehensive Guide to Routine Maintenance

Introduction:

Diesel generators are essential equipment that provide backup power during emergencies, blackouts, or in remote locations where access to the power grid is limited. To keep your diesel generator running smoothly and efficiently, it is crucial to perform routine maintenance regularly. This article will provide a comprehensive guide to maintaining your diesel generator to ensure its reliability and longevity.

Chapter 1: Understanding the Basics of Diesel Generators

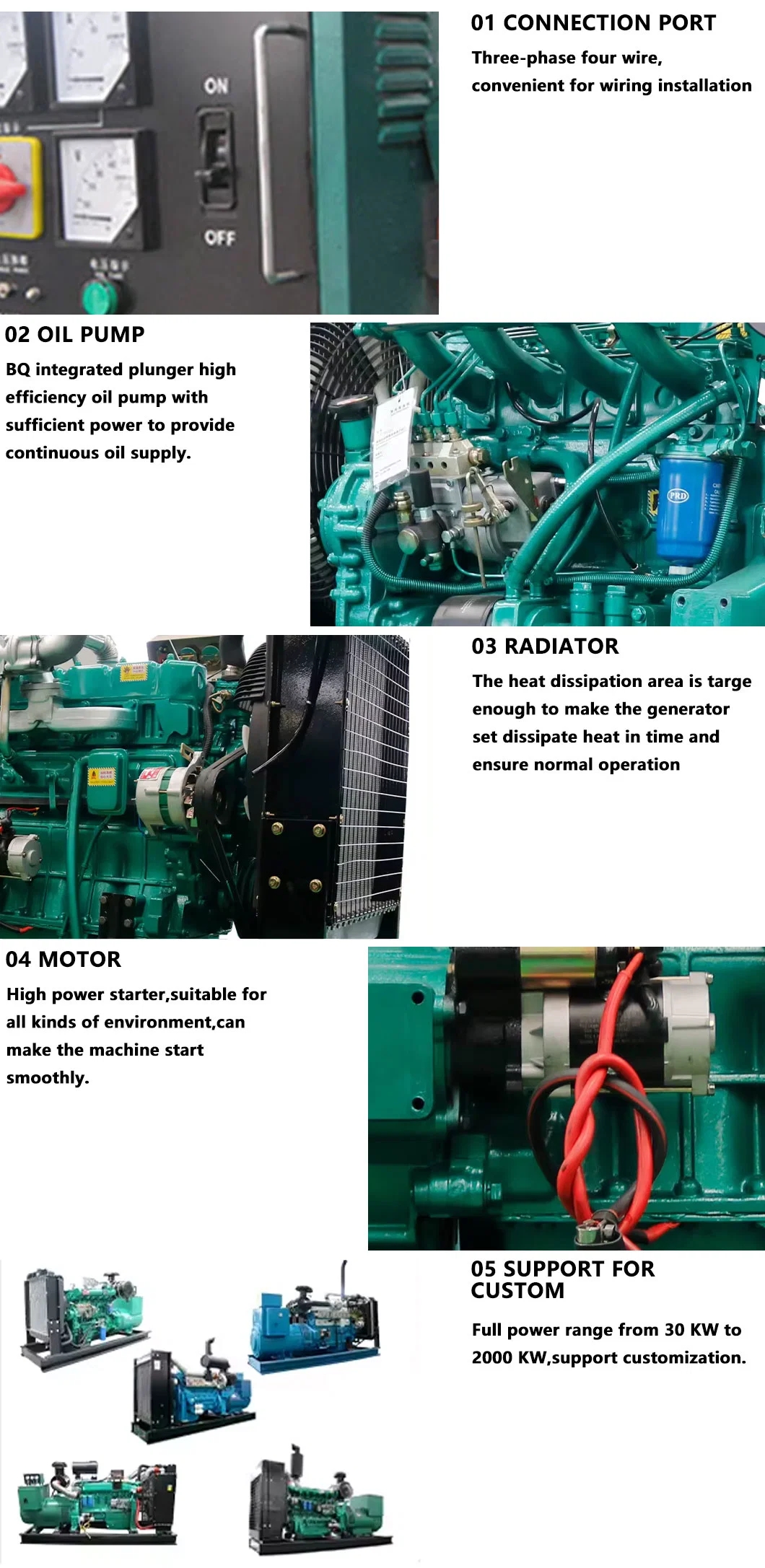

Before delving into the maintenance procedures, it is important to understand the basic components and functioning of a diesel generator. Diesel generators consist of an engine, alternator, fuel system, cooling system, exhaust system, and control panel. The engine, powered by diesel fuel, drives the alternator to generate electricity. The alternator converts mechanical energy into electrical energy, which is then distributed to power electrical devices. The fuel system delivers diesel fuel to the engine, while the cooling system regulates the engine temperature. The exhaust system removes combustion gases, and the control panel monitors and controls the generator's operation.

Chapter 2: Importance of Routine Maintenance

Routine maintenance is essential for diesel generators to ensure optimal performance, reliability, and longevity. Neglecting maintenance can lead to breakdowns, reduced efficiency, increased fuel consumption, and costly repairs. By following a regular maintenance schedule, you can prevent potential issues, extend the lifespan of your generator, and minimize downtime during emergencies. Additionally, proper maintenance can help identify small problems before they escalate into major issues, saving you time and money in the long run.

Chapter 3: Creating a Maintenance Schedule

To effectively maintain your diesel generator, it is important to create a maintenance schedule based on the manufacturer's recommendations and guidelines. A typical maintenance schedule includes daily, weekly, monthly, quarterly, and annual tasks. Daily checks may involve inspecting fluid levels, checking for leaks, and monitoring the control panel for any alerts. Weekly tasks may include testing the battery, checking the fuel level, and inspecting the cooling system. Monthly maintenance may involve changing the oil and filters, while quarterly tasks may include testing the generator under load and inspecting the belts and hoses. Annual maintenance should include more thorough inspections, such as checking the electrical connections, fuel injection system, and exhaust system.

Chapter 4: Daily Maintenance Tasks

Daily maintenance tasks are essential for ensuring the proper functioning of your diesel generator. These tasks are quick and simple but can have a significant impact on the performance and reliability of your generator. Daily tasks may include:

- Checking the fuel level: Ensure that the fuel tank is adequately filled to avoid running out of fuel during an emergency.

- Inspecting fluid levels: Check the oil, coolant, and other fluid levels to ensure they are at the recommended levels.

- Monitoring the control panel: Check the control panel for any alerts, warnings, or error codes that may indicate a problem.

- Inspecting for leaks: Look for any signs of leaks, such as oil or coolant leaks, and address them promptly.

- Checking the battery: Test the battery voltage and inspect the connections to ensure proper operation.

Chapter 5: Weekly Maintenance Tasks

Weekly maintenance tasks are slightly more involved than daily tasks and may require more time and effort. These tasks focus on checking critical components and systems to identify any potential issues early on. Weekly tasks may include:

- Testing the battery: Conduct a load test on the battery to ensure it can hold a charge and start the generator when needed.

- Checking the fuel level: Monitor the fuel level and top up if necessary to ensure uninterrupted operation.

- Inspecting the cooling system: Check the coolant level and inspect the radiator, hoses, and water pump for any leaks or damage.

- Inspecting the air filter: Clean or replace the air filter if it is dirty or clogged to ensure proper airflow to the engine.

- Checking for loose connections: Inspect electrical connections, terminals, and wiring for any signs of corrosion, looseness, or damage.

Chapter 6: Monthly Maintenance Tasks

Monthly maintenance tasks are more comprehensive and involve servicing key components of the diesel generator. These tasks are crucial for ensuring the long-term reliability and efficiency of the generator. Monthly tasks may include:

- Changing the oil and filters: Replace the engine oil and oil filter to remove contaminants and ensure proper lubrication of the engine.

- Inspecting the fuel system: Check the fuel lines, filters, and injectors for any blockages, leaks, or signs of wear.

- Testing the coolant: Check the coolant concentration and condition, and top up or replace it if necessary to prevent overheating.

- Inspecting the belts and hoses: Check the drive belts for wear and tension, and inspect the hoses for leaks, cracks, or bulges.

- Testing the automatic transfer switch: Verify the operation of the automatic transfer switch by simulating a power outage and ensuring the generator starts and transfers power seamlessly.

Chapter 7: Quarterly Maintenance Tasks

Quarterly maintenance tasks are more in-depth and involve testing the generator under load to assess its performance and reliability. These tasks help identify any issues that may arise during extended operation or high-demand situations. Quarterly tasks may include:

- Load testing the generator: Run the generator under load for a specified period to verify its capacity and performance.

- Inspecting the exhaust system: Check the exhaust manifold, muffler, and piping for leaks, corrosion, or damage that may affect engine performance.

- Inspecting 300KW Diesel Generator For Sale : Check the terminals, wiring, and connections for corrosion, tightness, and proper insulation.

- Cleaning the generator: Remove dust, dirt, and debris from the generator and surrounding area to prevent overheating and improve airflow.

- Inspecting the control panel: Test the control panel functions, alarms, and shutdown systems to ensure they are working correctly.

Chapter 8: Annual Maintenance Tasks

Annual maintenance tasks are comprehensive and involve a thorough inspection and servicing of all critical components of the diesel generator. These tasks are crucial for detecting any potential issues before they escalate into major problems. Annual tasks may include:

- Inspecting the engine: Check the engine for signs of wear, leaks, or damage, and perform any necessary repairs or adjustments.

- Testing the fuel injection system: Verify the operation of the fuel injectors, pumps, and lines to ensure proper fuel delivery.

- Inspecting the exhaust system: Check the exhaust manifold, turbocharger, muffler, and piping for signs of corrosion, leaks, or damage.

- Testing the voltage regulator: Verify the operation of the voltage regulator to ensure stable voltage output under varying loads.

- Inspecting the governor system: Check the governor for proper operation and adjust the speed settings if necessary to maintain stable engine speed.

Chapter 9: Troubleshooting Common Issues

Despite regular maintenance, diesel generators may encounter common issues that require troubleshooting and repairs. Some common problems include:

- Poor starting or no start: Check the battery voltage, fuel level, and starter motor for any issues that may prevent the generator from starting.

- Overheating: Inspect the cooling system for leaks, blockages, or low coolant level that may cause the engine to overheat.

- Low oil pressure: Check the oil level and pressure sensor for any issues that may cause low oil pressure and trigger an alarm.

- Excessive smoke: Inspect the air filter, fuel system, and exhaust system for any issues that may cause excessive smoke or emissions.

- Voltage fluctuations: Test the voltage regulator, alternator, and electrical connections for any issues that may cause voltage fluctuations or unstable power output.

Chapter 10: Conclusion

Maintaining your diesel generator is essential for ensuring its reliability, efficiency, and longevity. By following a regular maintenance schedule and performing routine checks and tasks, you can prevent potential issues, extend the lifespan of your generator, and minimize downtime during emergencies. Remember to consult the manufacturer's guidelines and recommendations for specific maintenance procedures and intervals. A well-maintained diesel generator will provide you with peace of mind knowing that you have a reliable backup power source when you need it most.