Choosing the Right Wire Bonding Method for Your Needs

Introduction

In the world of electronics and semiconductor production, the twine bonding process serves as a obligatory link among system, guaranteeing that they speak with no trouble. As expertise keeps to conform, figuring out easy methods to pick the desirable twine bonding formula becomes a must-have not just for engineers yet for a person interested in electronics construction.

This article ambitions to deliver an exhaustive evaluation of more than a few twine bonding technologies, ideas, and system to be had immediately. By diving deep into issues starting from gold vs. aluminum wire bonding to twine bonding reliability, we're going to ebook you simply by the complexities of choosing the superior method adapted for your selected demands.

What is Wire Bonding?

Wire bonding is a methodology used to create interconnections between semiconductor devices like included circuits (ICs) and their packaging. Essentially, it establishes electric connections the usage of superb wires product of gold, aluminum, copper, or different metals. The twine bonding task is needed for guaranteeing strong overall performance in electronic instruments.

The Importance of Wire Bonding in Electronics

Wire bonding performs a pivotal function in glossy electronics through:

Facilitating connections in IC packaging Connecting chips in multi-chip modules Enabling verbal exchange among diversified electronic components

Without successful twine bonding tactics and methodologies, many technological developments we enjoy in these days may be fantastic.

Wire Bonding Process Overview

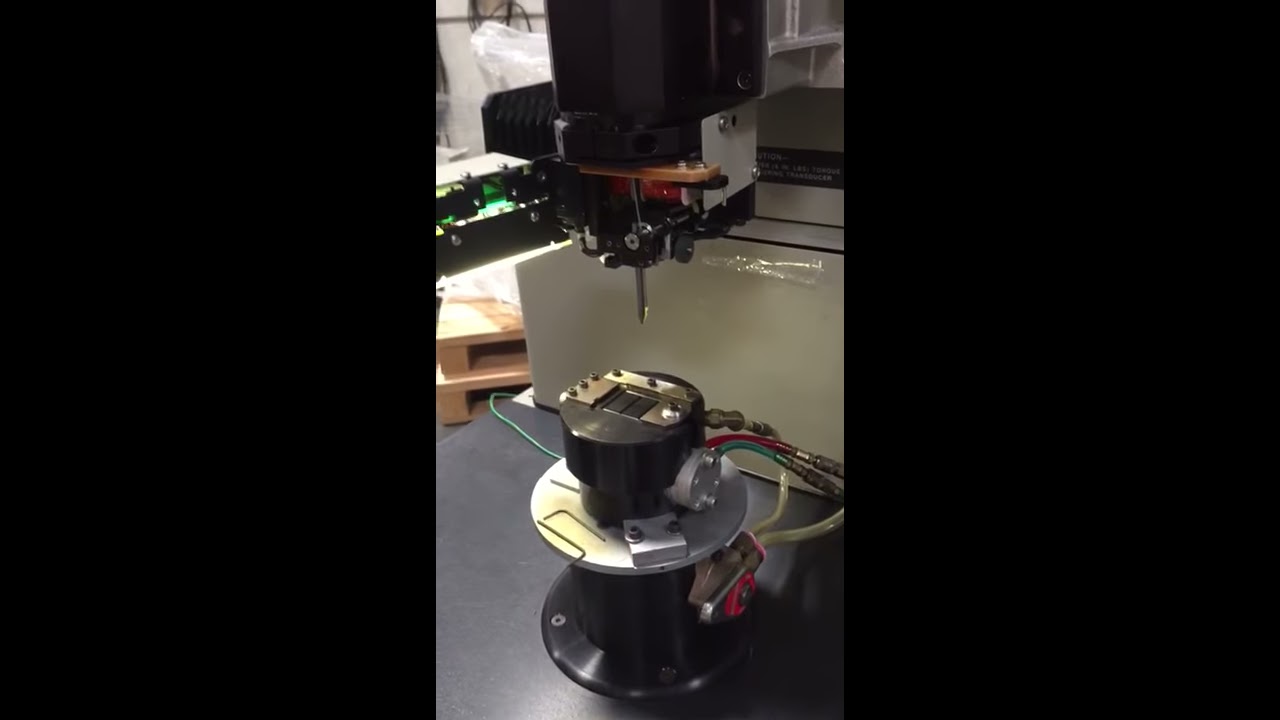

Understanding how cord bonding works is critical beforehand diving into selected techniques. The approach usually involves three essential steps:

Preparation: This carries cleaning surfaces and preparing the bond pads. Bonding: The truly strategy in which the cord is hooked up either simply by thermosonic or ultrasonic manner. Inspection: Quality regulate measures are taken to be certain that positive bonds.

Types of Wire Bonding Techniques

There are a few types of wire bonding ways, each one with its exciting functions:

Ball Bonding: Often hottest for its simplicity and effectiveness. Wedge Bonding: Ideal for prime-velocity functions. Ribbon Bonding: Suitable for thicker wires utilized in continual modules.

These ways can differ notably founded on motives together with textile form (gold vs aluminum), bond capability specifications, and environmental situations.

Choosing the Right Wire Bonding Method for Your Needs

Selecting the precise twine bonding method hinges on different factors such as check considerations, fabrics used, wanted bond reliability, and alertness specifics.

Factors Influencing Your Choice

Material Compatibility: Gold twine bonding excels in low-rigidity environments even as aluminum affords rate-superb recommendations. Bond Strength Requirements: For severe applications like car electronics or aerospace elements, amazing bonds are non-negotiable. Production Volume: High-volume manufacturing also can necessitate computerized machines in a position to quick-paced operations.

Cost Implications

Cost can very much have an impact on your resolution of twine bonding programs. Ball and wedge bonder machines can differ substantially in expense centered on features like automation degree and precision expertise.

Table 1: Cost Comparison of Different Methods

| Method | Initial Cost | Operating Cost | Typical Applications | |----------------|--------------|----------------|------------------------------------------------| | Ball Bonding | Moderate | Medium | Microelectronics | | Wedge Bonding | High | Low | Automotive & Aerospace Electronics | | Ribbon Bonding | High | Medium | Power Modules |

Understanding Different Types of Wire Bonding

Gold Wire Bonding

Gold cord bonding stays one of many most wide-spread systems owing to its glorious conductivity and resistance to oxidation. It’s usually applied in top-frequency purposes since it delivers greater functionality qualities.

Advantages:

Exceptional conductivity Corrosion resistance

Disadvantages:

Higher material rates compared to aluminum

Aluminum Wire Bonding

For can charge-sensitive projects requiring respectable overall performance with no breaking the bank, aluminum twine bonding is quite often favored.

Advantages:

Lower textile costs Good mechanical properties

Disadvantages:

Less conductive than gold Susceptible to oxidation except proper treated

Copper Wire Bonding

Copper has emerged as a robust alternative because of its appropriate conductivity and decrease money relative to gold.

Advantages:

Low-settlement material Excellent thermal properties

Disadvantages:

Requires cautious coping with due to oxidation issues

Wire Bond Quality Control Measures

Quality keep watch over for the period of the wire bonding job is important for guaranteeing long-term reliability of electronic merchandise.

Common Inspection Techniques

Visual Inspection: Manual assessments support title apparent defects. X-ray Inspection: Non-negative trying out that makes it possible for inside inspection. Pull Tests: Measures bond potential via utilizing drive except failure takes place.

Table 2: Types of Inspection Techniques

| Technique | Description | |-----------------------------|------------------------------------------| | Visual Inspection | Manual test for floor defects | | X-Ray Inspection | Non-unfavourable inside inspection | | Pull Test | Measures bond force |

FAQ Section

1. What is the most productive subject material for wire bonding?

Gold gives you well suited conductivity but comes at a top rate money; aluminum serves as a extra most economical selection with enough efficiency for lots programs.

2. How do I pick out among ball bond vs wedge bond?

Consider your software's velocity standards; ball bonds are aas a rule less difficult but wedges offer larger overall performance at top speeds.

3. What are commonly used screw ups all the way through twine bonding?

Common failure modes encompass bond lifting, heel cracks, and infection for the period of processing which may degrade excellent over the years.

4. How does environmental manage have an impact on twine bonding?

Environmental reasons comparable to humidity can have an affect on adhesion; controlling temperature and moisture levels guarantees preferable circumstances for winning bonds.

five. Are there any lessons tools obtainable?

Yes! Various online guides supply finished tutorials on alternative points of wire bonding along with purposeful demonstrations by way of video wire bonding services content material or downloadable PDFs.

6. What industries generally make use of cord bonding?

Industries consisting of automobile electronics, aerospace engineering, medical contraptions manufacture, LED creation utilize these approaches closely as a consequence of their reliability specifications.

Conclusion

Choosing the appropriate twine bonding technique for your wants calls for cautious consideration of various factors which includes subject material prices, manufacturing volume, required bond energy, and targeted software needs. Understanding the ins-and-outs—from models like ball or wedge bonds to best manage measures—will place you good inside this difficult area of know-how.

As call for maintains to develop throughout sectors comparable to automobile electronics or aerospace science in which strong connections are paramount—staying abreast with improvements like ribbon wiring inventions will hinder you competitive! Whether you're an engineer trying to refine your talent via really good programs or without problems need perception into marketplace tendencies—the pursuit doesn't end here; or not it's ever-evolving!

By making counseled picks relating to processes and equipment tailor-made specifically in the direction of challenge requirements—companies can make stronger effectivity while chopping overall operational rates—all while paving progressive pathways ahead inside of today's dynamic market!