Understanding the Ribbon Bonding Process and Its Benefits

Introduction

In the ever-evolving panorama of electronics manufacturing, one procedure stands proud for its performance and effectiveness: the ribbon bonding activity. As digital contraptions cut down in length although rising in complexity, the call for for reliable interconnections will become paramount. This article delves into the intricacies of ribbon bonding, exploring its purposes, strategies, advantages, and demanding situations.

The ribbon bonding strategy is a key manner in wire bonding know-how, pretty much utilized in semiconductor packaging. It grants numerous blessings over usual bonding tips reminiscent of ball and wedge bonding. By understanding the ribbon bonding technique and its blessings, stakeholders can make instructed decisions related to their production decisions.

Understanding the Ribbon Bonding Process

What Is Ribbon Bonding?

Ribbon bonding is a specialized shape of wire bonding that employs a flat ribbon of metallic in place of a around cord to create electrical connections among semiconductor chips and their substrates or packaging. The ribbons are most likely created from ingredients like gold, aluminum, or copper and might fluctuate in width depending on different program specifications.

How Does Ribbon Bonding Work?

The ribbon bonding strategy entails a few steps:

Preparation: The surfaces to be bonded are very well cleaned to get rid of any contaminants.

Positioning: The semiconductor die is accurately aligned with the substrate with the aid of computerized device.

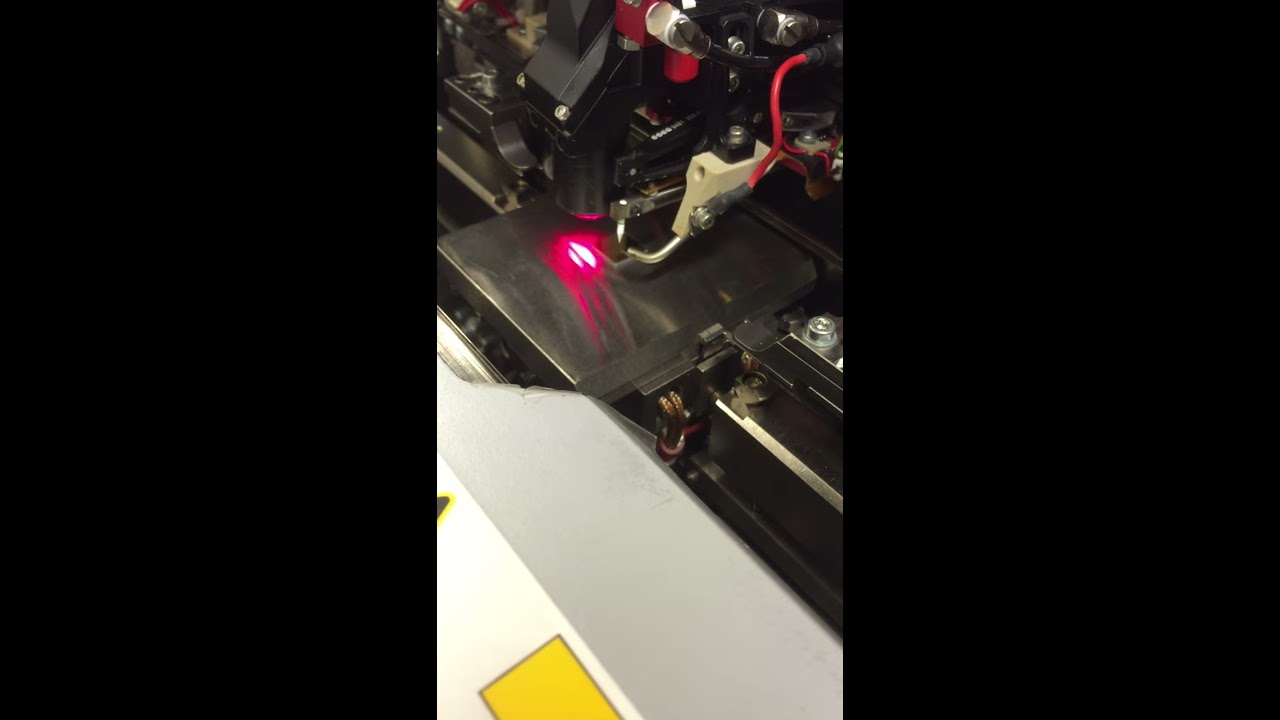

Bonding: A ribbon is then located onto the bond pad, the place an ultrasonic or thermosonic vigour resource applies strength and warmth to create a good bond.

Loop Formation: The ribbon is looped to succeed in any other bond pad, wherein the identical strategy is repeated.

Inspection: After completing the bonds, varying inspection techniques be certain that each and every connection meets excellent ideas.

Advantages of Ribbon Bonding

Higher Reliability: Ribbon bonds convey ideal mechanical force when put next to standard cord bonds.

Reduced Inductance: Due to the flat form of ribbons, they deliver shrink inductance paths which might be a very powerful for high-frequency applications.

Space Efficiency: Ribbons is additionally laid out extra compactly than wires, making them just right for densely packed circuit forums.

Applications of Ribbon Bonding

Ribbon bonding finds vast use in varying sectors including:

Semiconductors: Used for interconnections in incorporated circuits (ICs).

Power Modules: Essential for excessive-energy purposes by way of their robustness.

LED Manufacturing: Provides effective connections obligatory for LED functionality.

Automotive Electronics: Helps be sure that reliability under harsh circumstances normal in automotive environments.

Types of Wire Bonding Processes

Overview of Wire Bonding Techniques

Wire bonding encompasses a couple of methodologies including:

Ball Bonding Wedge Bonding Ribbon Bonding Flip Chip Bonding

Each way has its very own different benefits and disadvantages depending on program requirements.

Comparison of Techniques

| Technique | Advantages | Disadvantages | |--------------------|-----------------------------------------|----------------------------------------| | Ball Bonding | Simple setup; Suitable for quality pitch | Limited bond power | | Wedge Bonding | High capability; Versatile | Requires definite alignment | | Ribbon Bonding | Low inductance; Space-productive | Complex kit required | | Flip Chip Bonding | Direct touch; Lower resistance | Higher manufacturing costs |

Wire Bonding Equipment Used in Ribbon Bonding

Essential Tools and Machines

The good fortune of ribbon bonding extensively relies on complex machinery designed above all for this aim:

Ribbon Bonding Machines: Automated machines in a position to handling multi-die setups efficiently.

Bond Capillary Tools: Specialized resources used to manipulate ribbons right through bonding operations.

Programmable Wire Bonders: Machines that enable customization based mostly on exceptional program needs.

How to Choose the Right Equipment?

When deciding upon a cord bonding desktop for ribbon bonding methods, be aware components consisting of:

Desired bond strength Production volume Compatibility with special material (gold vs aluminum)

Always discuss with manufacturers to recognize which apparatus ideal matches your distinct application requirements.

Quality Control in Wire Bonding

Importance of Quality Control Measures

Quality management (QC) is obligatory at some stage in the cord bonding procedure as it ensures reliability and overall performance principles are met.

Key QC Techniques Include:

Visual Inspection X-ray Inspection Pull Test Analysis

Each formula can provide primary understanding about bond integrity and ordinary product first-rate.

Common Wire Bond Failures and Their Analysis

Types of Wire Bond Failures:

Heel Cracks Oxidation Issues Incomplete Bonds

Understanding those mess ups allows for engineers to implement corrective actions safely.

Technical Challenges in Ribbon Bonding

Addressing Common Technical Issues

While ribbon bonding gives you a considerable number of advantages, it additionally offers exact challenges that have to be addressed:

1. Environmental Factors:

Dust or moisture can compromise bond caliber; to that end keeping up cleanroom circumstances is basic.

2. Material Compatibility:

Choosing incompatible parts can bring about oxidation or degradation over time.

three. Process Variability:

Variations in temperature or power right through the bonding stage can cause inconsistent great.

Ribbon vs Wedge vs Ball Bonding Processes

Comparison Overview

When figuring out which wire-bond system premier fits your needs, it is primary to keep in mind how they stack up against every one other:

| Parameter | Ribbon Bonding | Wedge Bonding | Ball Bonding | |--------------------|-----------------------------------|-------------------------------------|-----------------------------------| | Cost | Moderate | Variable | Lower | | Application Suitability| High frequency designs | General-motive | Microelectronics | | Strength | High | Very High | Moderate |

Future Trends in Wire Bond Technology

As technology advances, so do twine bonding practices:

Increased automation will toughen precision. Innovations will lead toward even thinner wires making sure greater functionality stages. Ongoing investigation into choice resources will support shrink ordinary charges even as asserting good quality requisites.

FAQs About Ribbon Bonding Process

What is ribbon bonding?

Ribbon bonding refers to growing electric connections by way of a flat metallic strip (ribbon) in place of usual around wires among semiconductor aspects.

What are overall elements used in ribbon bonds?

Gold and aluminum are characteristically used by way of their magnificent conductivity houses; in spite of the fact that, copper has gained status as it’s extra expense-useful.

How does ribbon bonding examine with ball or wedge tools?

While all three tactics serve interconnection functions inside electronics manufacturing contexts—ribbon delivers scale down inductance making it exact for excessive-frequency applications the place space effectivity matters such a lot.

Can I automate my ribbon bond approach?

Yes! Many sleek machines provide programmable elements allowing greater productivity by way of automation whilst minimizing human error hazards associated with handbook strategies.

Are there any challenges associated with by using ribbons instead of traditional wires?

Yes! Some energy complications encompass environmental sensitivity most appropriate against infection hazards alongside materials compatibility difficulties if not monitored safely in the time of creation workflows!

How do I ensure positive outcomes while imposing this methodology?

Implement rigorous first-class regulate protocols all through each and every degree from preparation through Check out here remaining inspections—making use of visible checks along improved trying out technology like X-rays!

Conclusion

In conclusion, knowing the ribbon bonding approach is elementary for absolutely everyone fascinated in electronics manufacturing nowadays—it combines ultra-modern technologies with tough engineering concepts guaranteeing reliability across quite a number functions! As units proceed evolving in direction of larger complexity requiring a growing number of compact ideas—the relevance behind adopting advantageous systems round these tactics becomes clearer than ever prior to! By leveraging ideal insights into each advantages & demanding situations surrounding this cutting edge mindset—we pave our method closer to figuring out innovations across industries reliant upon tremendous electronic resources—making certain they meet shopper demands now & into future generations!