Enhancing EMC Testing with Diesel Generators

Introduction

Electromagnetic compatibility (EMC) testing is crucial for ensuring that electronic devices operate efficiently without interfering with other equipment. To conduct accurate and reliable EMC testing, it is essential to have a stable and reliable power source. Diesel generators offer a cost-effective and efficient solution for providing the necessary power during EMC testing procedures. In this article, we will explore the significance of diesel generators in EMC testing and how they enhance the testing process.

Understanding EMC Testing

EMC testing is a critical part of the product development process for manufacturers of electronic devices. It involves assessing the ability of a device to function correctly in its electromagnetic environment without causing interference to other devices. https://www.lkpowerplant.com/product/300kw-375kva-portable-engine-brand-new-diesel-generator-set/ helps ensure that electronic products meet regulatory standards and operate safely and reliably.

There are two main types of EMC testing: emission testing and immunity testing. Emission testing evaluates the electromagnetic emissions produced by a device, such as radio frequency interference (RFI) or electromagnetic interference (EMI). Immunity testing, on the other hand, assesses the device's ability to withstand electromagnetic interference from external sources without malfunctioning.

To conduct EMC testing accurately, it is essential to create a controlled testing environment free from external interference. This includes ensuring a stable power supply that is free from electrical noise and fluctuations. A reliable power source is crucial for maintaining the integrity of the testing process and obtaining accurate results.

The Role of Diesel Generators in EMC Testing

Diesel generators play a vital role in EMC testing by providing a stable and reliable power supply to the testing equipment. Unlike grid power, which can be prone to fluctuations and interruptions, diesel generators offer a consistent source of power that is essential for conducting precise and repeatable tests.

One of the key advantages of diesel generators in EMC testing is their ability to deliver high levels of power output. EMC testing equipment often requires a significant amount of power to operate efficiently, and diesel generators are capable of meeting these power demands without compromising performance. This ensures that the testing process can proceed smoothly without any interruptions due to power issues.

Moreover, diesel generators are known for their durability and reliability, making them ideal for use in demanding testing environments. They can withstand extended periods of operation and provide continuous power supply without experiencing performance degradation. This reliability is crucial for ensuring the accuracy and consistency of EMC test results.

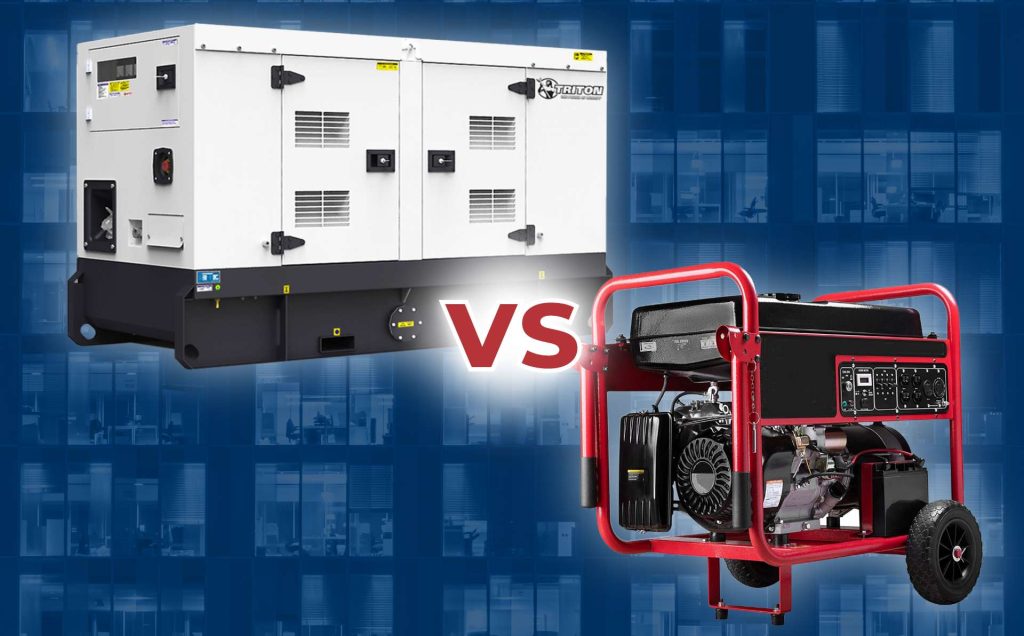

Another benefit of diesel generators in EMC testing is their portability and ease of deployment. Diesel generators are available in a range of sizes and configurations, making them suitable for various testing setups and environments. Their mobility allows for flexibility in setting up the testing equipment and adapting to different testing requirements.

Additionally, diesel generators are cost-effective compared to other power sources, such as uninterruptible power supply (UPS) systems or grid power. They offer a more affordable solution for providing the necessary power during EMC testing without compromising on performance or reliability. This cost-effectiveness makes diesel generators a practical choice for manufacturers conducting EMC testing on a regular basis.

Best Practices for Using Diesel Generators in EMC Testing

To maximize the benefits of diesel generators in EMC testing, it is essential to follow best practices for their installation and operation. Here are some key considerations to keep in mind when using diesel generators for EMC testing:

1. Proper Sizing: Ensure that the diesel generator is properly sized to meet the power requirements of the EMC testing equipment. Oversized or undersized generators can lead to inefficiencies and affect the accuracy of the test results. Consult with a professional to determine the appropriate generator size for your specific testing needs.

2. Regular Maintenance: Perform regular maintenance checks and servicing of the diesel generator to ensure optimal performance and reliability. This includes monitoring fuel levels, changing filters, and inspecting critical components for any signs of wear or damage. Scheduled maintenance helps prevent unexpected breakdowns during testing procedures.

3. Fuel Quality: Use high-quality diesel fuel to power the generator and prevent issues such as clogging or contamination. Proper fuel management is essential for ensuring the reliable operation of the generator and maintaining consistent power output during testing.

4. Noise and Emissions Control: Consider noise and emissions control measures when using diesel generators in indoor testing environments. Install soundproofing materials and exhaust systems to minimize noise levels and maintain a safe working environment for testing personnel.

5. Backup Power Source: Have a backup power source or contingency plan in place in case of generator failure or power outage during EMC testing. This ensures continuity of the testing process and prevents data loss or equipment damage due to sudden power disruptions.

Conclusion

Diesel generators play a crucial role in enhancing EMC testing by providing a stable and reliable power supply to testing equipment. Their high power output, durability, and cost-effectiveness make them an ideal choice for manufacturers conducting EMC testing on electronic devices. By following best practices for using diesel generators in EMC testing, manufacturers can ensure accurate and consistent test results while maintaining a safe and efficient testing environment. Incorporating diesel generators into EMC testing procedures can help streamline the testing process and improve overall product quality and compliance with regulatory standards.