From Preparation to Dismantling: The Scaffolding Lifecycle

Avoiding Typical Scaffolding Errors: Finest Practices

To avoid typical scaffolding mistakes, adhere to ideal methods: strategy thoroughly for safety and efficiency, select top notch products like steel or aluminum, warranty safe and secure setting up utilizing appropriate attachment techniques, supply detailed employee training on secure methods, apply fall prevention measures like guardrails, and observe laws with normal examinations and documentation. Correct preparation, material choice, assembly, worker training, precaution, and compliance with regulations are vital. This concise overview highlights critical action in scaffold safety and security.

Relevance of Proper Scaffolding Preparation

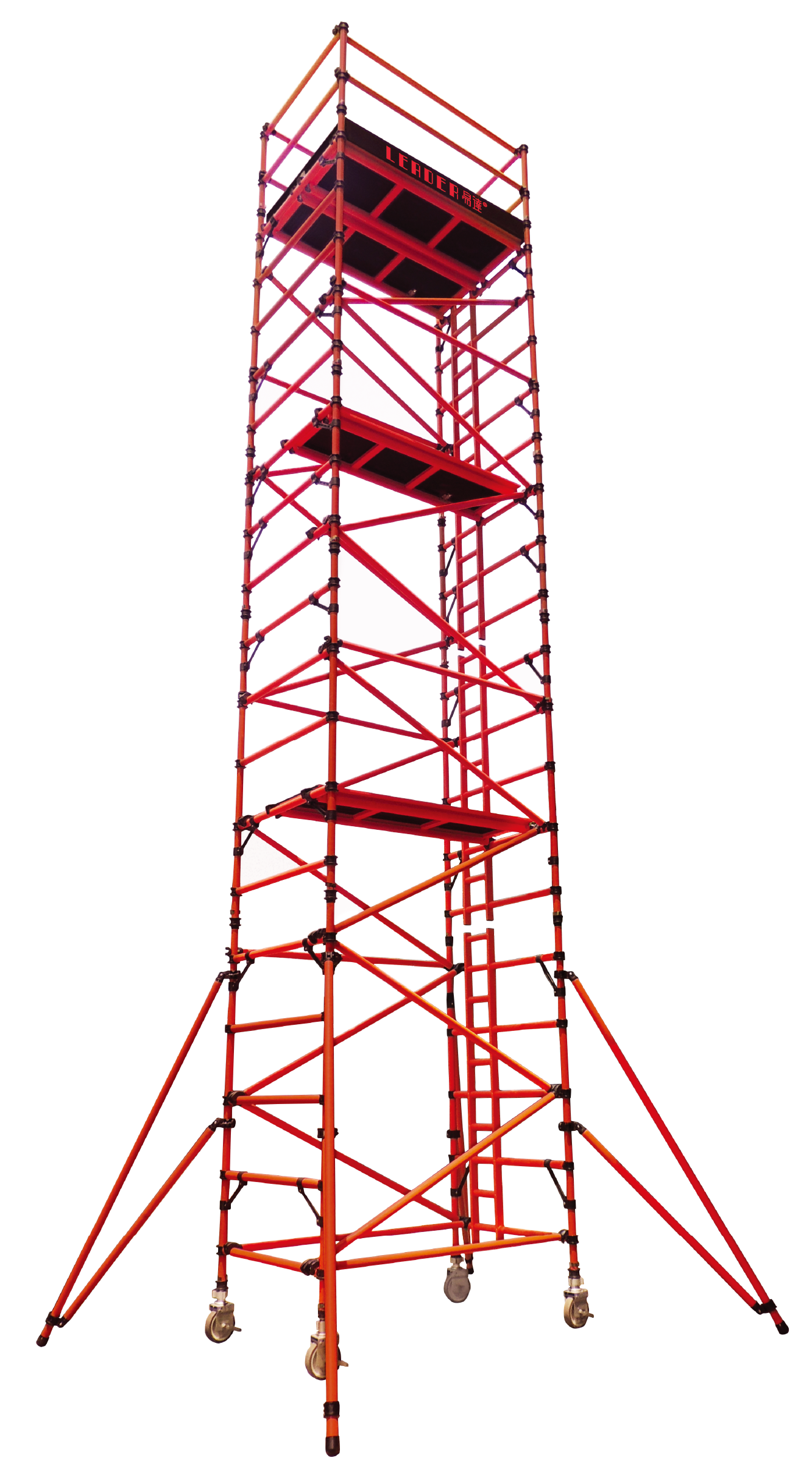

Reliable scaffolding preparation is essential for making sure the safety and performance of building and construction projects. Correct design and efficient use of scaffolding are essential facets that must be thought about during the preparation phase. Proper style involves producing a thorough design that thinks about the particular requirements of the project, including the elevation, weight capability, and load-bearing capacities needed. By making sure the scaffolding is developed correctly from the beginning, potential dangers and security threats can be reduced.

Efficient use of scaffolding involves using the framework in a manner that maximizes productivity while keeping safety requirements. This consists of making certain that the scaffolding is erected according to the manufacturer's guidelines and sector guidelines. Correct training of employees on just how to use the scaffolding correctly is likewise essential to stop accidents and injuries on the construction website. Furthermore, routine evaluations and upkeep of the scaffolding are important to identify any problems beforehand and address them quickly.

Selecting the Right Scaffolding Products

Picking the proper scaffolding materials is a vital choice that significantly influences the safety and security and performance of construction jobs. Proper maintenance and material choice are essential aspects to ponder when selecting the right scaffolding materials.

When it concerns material choice, it is important to go with premium products that fulfill safety requirements. Steel and aluminum are common selections due to their resilience and stamina. Steel scaffolding is durable and appropriate for durable tasks, while light weight aluminum scaffolding is lightweight and corrosion-resistant, perfect for projects calling for frequent assembly and disassembly. https://towerhamletsscaffolding.co.uk/index.html

Proper upkeep of scaffolding products is vital to ensure their durability and security. Routine examinations should be carried out to determine any signs of wear and tear, rust, or damages. Any type of harmed parts need to be repaired or replaced immediately to avoid crashes on the building and construction site.

Making Certain Secure Scaffold Assembly

To ensure protected scaffold assembly, it is essential to comply with a precaution list, conduct correct equipment assessments, and use safe fastening methods.

These techniques are vital in keeping a risk-free workplace and avoiding crashes or injuries on building sites.

Precaution List

Ensuring a safe and secure scaffold assembly needs careful attention to safety measures throughout each action of the building and construction process. Security training plays an important duty in gearing up employees with the expertise to determine possible risks and implement correct safety and security protocols.

Before beginning work, guaranteeing that all workers entailed have gone through comprehensive safety training is crucial to stop mishaps and injuries. Additionally, extensive equipment inspection before scaffold assembly is important to verify that all elements remain in good problem and fulfill safety and security standards.

Frequently checking devices, materials, and the scaffold framework itself can help determine any prospective dangers and guarantee a risk-free working environment for all workers associated with the setting up procedure.

Proper Tools Evaluation

Evaluating the equipment completely prior to scaffold assembly is a crucial step in making sure a safe workplace for all employees included. To guarantee devices safety and correct capability, follow these inspection procedures:

- Aesthetic Exam: Check for any kind of visible damages, rust, or missing out on parts on all components.

- Functional Checking: Make sure that systems such as locking pins and adjustable components are functioning properly.

- Lots Capability Verification: Verify that the scaffold can safely support the designated weight by examining supplier specs and ability labels.

Following these examination procedures is important in preserving a safe scaffolding configuration. By focusing on devices safety and security through comprehensive examinations, the danger of accidents and injuries can be dramatically minimized.

Safeguard Attachment Techniques

Maintaining a safe scaffold setting up counts heavily on executing accurate and reliable securing methods. Attaching stability is critical to assure the safety and security and security of the scaffold structure.

Safe and secure connections in between various scaffold parts, such as frameworks, dental braces, and systems, are necessary to protect against accidents and structural failures. Using suitable bolts and complying with producer guidelines for tightening up torque specs are important steps in accomplishing a durable scaffold assembly.

Checking attachments frequently for indicators of wear, rust, or helping to loosen is likewise crucial to maintain the integrity of the scaffold. By focusing on attaching security and ensuring protected links throughout the scaffold, construction groups can substantially lessen the dangers related to scaffold setting up and usage.

Normal Inspection and Upkeep Procedures

Regular assessment and upkeep procedures are vital elements of making certain scaffold safety and security. Arranged inspections aid recognize potential problems before they rise, while timely repair services deal with any worries immediately.

Paperwork of these procedures is important for regulative conformity and preserving a secure working environment.

Set Up Inspections for Safety

To guarantee the safety and durability of scaffolding structures, crucial checks and prompt maintenance are vital methods. Executing a thorough safety audit and sticking to a rigorous examination timetable are crucial components in guaranteeing the architectural stability of scaffolding.

Here are 3 important steps to consider:

- Conduct regular security audits to analyze possible dangers and conformity with safety criteria.

- Develop a thorough assessment timetable that lays out when and just how assessments will certainly be carried out.

- Train personnel in charge of assessments to identify safety and security concerns and execute necessary maintenance tasks without delay.

Trigger Service When Needed

Examining scaffolding routinely for safety and security is important to immediately deal with any kind of fixings required to preserve structural integrity. Timely repair work are necessary to ensure the safety of employees and the security of the framework. Establishing regular upkeep timetables can assist in determining prospective issues at an early stage.

Normal inspections ought to include checking for loosened bolts, damaged components, or any indications of wear and tear. Any type of determined issues need to be dealt with immediately by qualified workers to avoid accidents or structural failings. Preserving thorough documents of inspections and repairs can help in tracking the scaffolding's condition over time.

Documentation for Conformity

Applying a detailed paperwork system for conformity with normal evaluation and maintenance treatments is critical for guaranteeing the security and architectural honesty of scaffolding. To achieve this, think about the following:

- Routine Inspections: Conduct arranged inspections to recognize any problems without delay.

- Maintenance Records: Maintain thorough documents of maintenance tasks and repair services.

- Safety Training Paperwork: Make sure all employees associated with scaffolding job have obtained correct safety and security training and maintain records to show compliance.

Training Employees on Safe Scaffolding Practices

Appropriate training of workers on risk-free scaffolding methods is necessary to guarantee a secure workplace on building websites. Worker guidance plays a critical role in ensuring that employees adhere to safety protocols when dealing with scaffolding. Safety and security training must cover correct setting up and disassembly of scaffolding, appropriate installation of guardrails and toe boards, secure handling of materials on elevated platforms, and treatments to avoid falls. It is essential that workers are well-versed in acknowledging potential threats, such as unsteady ground problems, overhanging high-voltage line, or stormy weather condition, and understand exactly how to reduce these dangers properly.

Routine security meetings and refresher courses can help reinforce the significance of safe scaffolding techniques and keep employees informed concerning any kind of updates in safety and security laws. Employers should additionally supply access to individual safety devices (PPE) and ensure that employees are learnt its proper use. By prioritizing comprehensive safety training and continuous employee guidance, construction firms can decrease the possibility of scaffolding crashes and develop a safer work environment for all employees involved.

Compliance With Scaffolding Rules

To guarantee a secure working environment on building and construction websites, stringent adherence to scaffolding laws is vital. Regulative compliance and security criteria ought to be at the forefront of every building project to alleviate risks and make sure the well-being of workers.

Here are 3 key points to consider concerning compliance with scaffolding regulations:

- Routine Evaluations: Conduct frequent inspections of the scaffolding structure to identify any kind of prospective hazards or issues that could jeopardize its stability. https://towerhamletsscaffolding.co.uk Inspections should be performed by certified professionals and documented appropriately.

- Training and Qualification: Make sure that all employees working with or around scaffolding are properly trained and certified to do so. This includes understanding safety methods, appropriate assembly, and taking down procedures, in addition to emergency response measures.

- Documents and Record-Keeping: Maintain in-depth records of evaluations, training qualifications, and any adjustments made to the scaffolding. Documents not just shows governing conformity but also acts as a useful resource for future recommendation and enhancement.

Often Asked Inquiries

What Are Some Typical Errors to Stay Clear Of When Taking Apart Scaffolding?

When taking apart scaffolding, it is necessary to make use of appropriate technique to prevent crashes. Normal tools maintenance is crucial for secure procedures. Following these practices ensures a protected workplace and minimizes risks.

How Can Weather Issues Effect the Safety of Scaffolding Structures?

Weather condition effects can significantly influence the security of scaffolding structures. Rain can compromise architectural stability, resulting in possible collapse. Keeping track of weather and taking needed safety measures, such as protecting the scaffolding, are crucial to preserving a secure workplace.

Are There Certain Guidelines for Utilizing Scaffolding on Uneven or Sloped Surface Areas?

When working on irregular or sloped surfaces, security problems are extremely important. Adhere to details guidelines for correct arrangement, making certain safety and security preventative measures are in place. Regular devices upkeep is vital to uphold security and avoid mishaps in such situations.

What Should Be Done if an Employee Encounters a Safety Problem While Utilizing Scaffolding?

If a worker comes across a security concern while utilizing scaffolding, they must right away stop work, report the issue to their supervisor adhering to the reporting treatment, and if needed, trigger the emergency situation reaction method to ensure every person's safety and security.

Exactly How Commonly Should Scaffolding Devices Be Replaced or Updated to Make Sure Safety And Security?

Scaffolding devices must be changed according to a fixed timetable based on manufacturer standards and use regularity. Upgrading frequency needs to straighten with technological improvements. Regular examinations and appropriate upkeep are critical to guarantee security compliance.

Conclusion

To sum up, correct scaffolding preparation is crucial. This includes picking ideal materials, making certain secure assembly, carrying out normal evaluation and upkeep, training employees on safe practices, and ensuring conformity with guidelines. By adhering to these best practices, the danger of crashes and injuries can be considerably reduced, developing a much safer work environment for all people involved in scaffolding procedures.

This extensive technique to scaffolding safety highlights the significance of extensive planning, efficient communication, and recurring caution in keeping a protected workplace.