Understanding the Importance of HVAC System Control Cables A Comprehensive Guide

Introduction

Heating, ventilation, and air conditioning (HVAC) systems are essential components of buildings, providing comfort and maintaining indoor air quality. These systems rely on various control mechanisms to regulate temperature, humidity, and airflow. Among these control mechanisms, HVAC system control cables play a crucial role in ensuring the efficient operation of the system. In this comprehensive guide, we will delve into the intricacies of HVAC system control cables, exploring their types, functions, installation methods, and maintenance requirements.

Types of HVAC System Control Cables

HVAC system control cables come in various types, each designed for specific applications within the system. Understanding the different types of control cables is essential for ensuring the optimal performance of the HVAC system. The following are some common types of HVAC system control cables:

1. Thermostat Cables: Thermostat cables are used to connect the thermostat to the HVAC system's control board. These cables carry signals from the thermostat to the control board, allowing users to adjust the temperature settings and control the operation of the HVAC system.

2. Control Cable Bundles: Control cable bundles consist of multiple cables bundled together to facilitate the connection of various components within the HVAC system. These cables are commonly used to connect sensors, actuators, and other control devices to the control board.

3. Signal Cables: Signal cables are used to transmit control signals between different components of the HVAC system, such as between the control board and the motorized dampers or valves. These cables are crucial for ensuring proper communication and coordination between the various parts of the system.

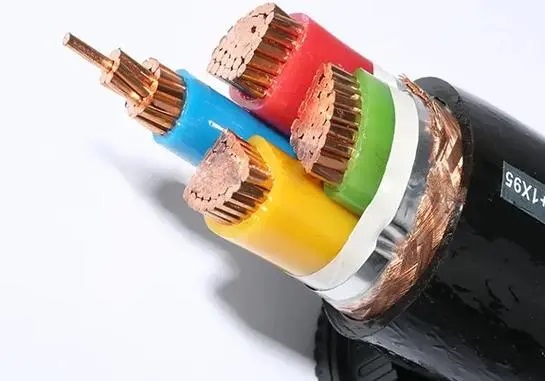

4. Power Cables: Power cables are used to supply electrical power to the different components of the HVAC system, such as the blower motor, compressor, and control board. These cables are designed to handle high electrical currents and voltages, ensuring the safe and reliable operation of the system.

Functions of HVAC System Control Cables

HVAC system control cables perform several key functions that are essential for the efficient operation of the system. Some of the primary functions of these cables include:

1. Signal Transmission: One of the main functions of HVAC system control cables is to transmit signals between the various components of the system. These signals are used to control the operation of the system, such as adjusting the temperature settings, activating the blower motor, or opening and closing dampers.

2. Power Distribution: Control cables also play a crucial role in distributing electrical power to the different components of the HVAC system. Power cables carry the necessary electrical currents to the motors, controllers, and other electrical devices, ensuring they operate as intended.

3. Communication: HVAC system control cables facilitate communication between the control board and the different sensors, actuators, and devices within the system. This communication is essential for monitoring system performance, detecting faults, and making real-time adjustments to ensure optimal operation.

4. Safety and Reliability: Control cables are designed to meet specific safety and reliability standards to ensure the safe and efficient operation of the HVAC system. Properly installed and maintained control cables help prevent electrical hazards, system malfunctions, and downtime.

Installation of HVAC System Control Cables

Proper installation of HVAC system control cables is crucial for ensuring the reliable and efficient operation of the system. The installation process involves several key steps that must be followed to ensure the cables are correctly configured and connected. The following are some essential guidelines for the installation of HVAC system control cables:

1. Planning: Before installing the control cables, it is essential to develop a detailed plan that outlines the cable routing, connections, and termination points. Consider factors such as cable lengths, signal integrity, and accessibility when planning the installation.

2. Cable Routing: Carefully route the control cables to avoid interference with other electrical wiring, plumbing, or structural elements within the building. Use cable trays, conduits, and supports to secure the cables and protect them from damage.

3. Connection and Termination: Properly connect and terminate the control cables at the designated points, following the manufacturer's recommendations and industry standards. Use appropriate connectors, terminals, and tools to ensure secure and reliable connections.

4. Testing and Commissioning: After installing the control cables, thoroughly test the system to ensure all connections are secure and functional. Verify signal continuity, voltage levels, and communication between the components to validate the installation.

5. Documentation: Keep detailed documentation of the control cable installation, including cable types, routing diagrams, termination points, and testing results. This documentation is valuable for troubleshooting, maintenance, and future upgrades.

Maintenance of HVAC System Control Cables

Regular maintenance of HVAC system control cables is essential for ensuring the continued performance and reliability of the system. Proper maintenance practices help prevent cable failures, signal disruptions, and system malfunctions. The following are some key maintenance tasks for HVAC system control cables:

1. Inspection: Periodically inspect the control cables for signs of wear, damage, or corrosion. Check for Flame retardant control cable , frayed insulation, or exposed wires that could compromise the integrity of the cables.

2. Cleaning: Keep the control cables clean and free of dust, dirt, and debris that could affect signal transmission and electrical conductivity. Use compressed air or a soft brush to remove any contaminants from the cables.

3. Testing: Regularly test the control cables to ensure they are functioning correctly. Use a multimeter or cable tester to measure signal continuity, resistance, and voltage levels to detect any issues before they escalate.

4. Repairs: Promptly repair any damaged or faulty control cables to prevent further deterioration and system downtime. Replace damaged cables, connectors, or terminals with new components following the manufacturer's recommendations.

5. Upgrades: Consider upgrading outdated or inefficient control cables to improve system performance and reliability. Upgrading to higher-quality cables with enhanced insulation, shielding, or signal transmission capabilities can help optimize the operation of the HVAC system.

Conclusion

HVAC system control cables are integral components that play a critical role in the operation of heating, ventilation, and air conditioning systems. Understanding the types, functions, installation methods, and maintenance requirements of control cables is essential for ensuring the reliable and efficient performance of the HVAC system. By following best practices for selecting, installing, and maintaining control cables, building owners, facility managers, and HVAC professionals can optimize system operation, maximize energy efficiency, and enhance occupant comfort.