The Silent Revolution 🤖 How Servo Motor Presses Are Reinventing Manufacturing One Perfect Stroke at a Time

The rhythmic *thud-thud-thud* echoed through the factory floor. For decades, it was the heartbeat of production, the sound of metal yielding under brute force. John, a production manager with grease perpetually under his fingernails, watched another stamped part land in the reject bin. Slight variation, barely perceptible to the eye, but enough to cause a downstream assembly headache tomorrow. He sighed. This was the old dance, the compromise between speed, precision, and cost. But somewhere, in forward-thinking factories, that relentless, unforgiving beat was being replaced… by near silence, and unparalleled perfection. The era of the servo motor press had arrived, not with a bang, but with a whisper and a surge of intelligent power. ⚡️

**Beyond the Hammer: Understanding the Servo Advantage**

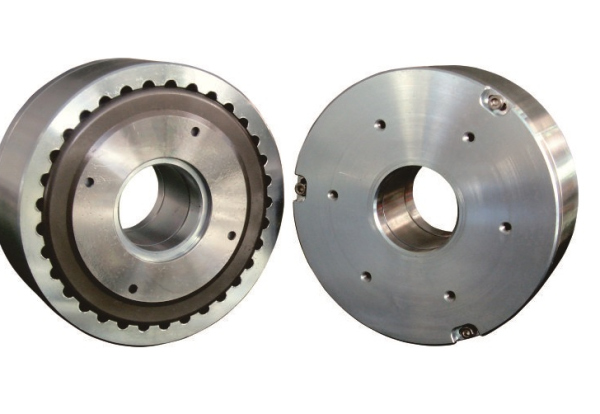

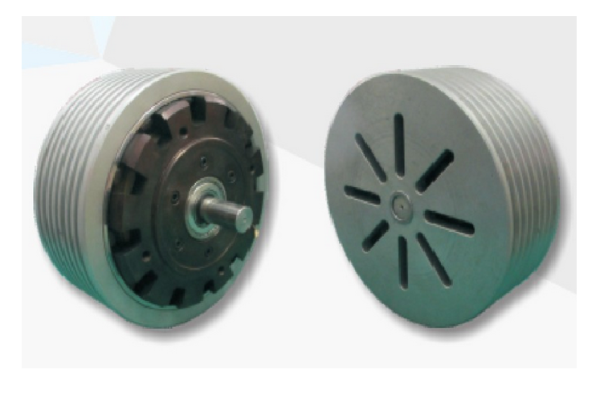

Forget everything you thought you knew about presses. Traditional mechanical presses? They're like a powerful but inflexible hammer. Hydraulics? Think of a strong, fluid-driven piston, often slow and energy-hungry. The servo motor press is fundamentally different. It’s more like a master sculptor with superhuman strength and micro-surgeon dexterity. At its core lies a sophisticated, high-torque electric servo motor driving a precision ball screw or link mechanism. This isn't just about moving a ram up and down; it’s about commanding its every single millimeter of travel, its speed, its force, and its dwell time with breathtaking accuracy.

Imagine this: Instead of being locked into a single, rigid motion profile dictated by a fixed flywheel and clutch, the servo press lets you *program* the ram’s journey. You design the ideal stroke for *your* specific part, *your* specific material, *your* specific quality requirement. This is programmability, flexibility, and intelligence baked directly into the machine's DNA.

**The Symphony of Precision: Unpacking the Game-Changing Benefits**

So, what does this technological leap translate to on the actual shop floor? Let’s listen to the music it creates:

1. **Unmatched Precision \u0026 Repeatability: The Heartbeat of Quality 🔍**

This is the crown jewel. Servo presses eliminate the inherent inconsistencies of mechanical systems – flywheel inertia, clutch wear, linkage slack. The servo motor, coupled with high-resolution encoders, provides closed-loop feedback control. Every single stroke is monitored and adjusted in real-time. Think micron-level accuracy, stroke after stroke, hour after hour, day after day. The result? Dramatically reduced scrap rates. Parts that fit perfectly, every single time. No more tolerance stack-ups causing assembly line nightmares. John’s reject bin? It starts gathering dust. Consistency becomes the norm, not the aspiration.

2. **Unprecedented Flexibility: One Machine, Infinite Possibilities 🎛️**

Need to switch from forming thin, delicate aluminum to thick, high-strength steel? On a traditional press, this often meant lengthy changeovers, tooling adjustments, maybe even machine settings tweaks that took skilled operators offline. With a servo press, you simply load a different program.

* **Stroke Length \u0026 Position:** Adjustable on the fly. Need a short stroke for shallow forming? Done. A longer stroke for deep drawing? Effortless. Need the ram to stop *exactly* 2.3mm above the die for an insert? Program it.

* **Speed Control:** This is revolutionary. You are no longer a prisoner of one speed dictated by motor RPM and gearing. You can program the ram to:

* Approach the material slowly and gently for precise alignment.

* Accelerate rapidly through the non-working portion of the stroke to save cycle time.

* Decelerate just before contact to minimize impact shock on delicate tooling or materials.

* Control the forming speed *during* the working stroke for optimal material flow and springback control.

* Dwell at the bottom of the stroke for a specific time – crucial for coining operations or plastic forming.

* Retract at a controlled speed.

This dynamic speed profile is impossible on traditional presses and unlocks new levels of process control and part quality.

* **Force Profiling:** Advanced servo presses can even monitor and control tonnage throughout the stroke, providing active protection against overloads and ensuring consistent forming force.

3. **Crushing Scrap Rates \u0026 Boosting Yield 💰**

Precision and flexibility are direct paths to profitability. How?

* **Reduced Setup Scrap:** Getting a new job dialed in is faster and produces fewer bad parts during setup because adjustments are digital and precise.

* **Eliminated Process Variation Defects:** Wrinkling, tearing, inconsistent dimensions, springback variation – these are drastically reduced or eliminated due to precise control over speed, dwell, and position.

* **Optimized Material Usage:** Precision means less over-engineering of blanks is needed to compensate for process variation.

* **Higher First-Pass Yield:** More good parts come off the press on the first try. This massive reduction in scrap translates directly to saved material costs, reduced rework costs, and less waste disposal. Your bottom line breathes a sigh of relief.

4. **Extending Tool Life: Protecting Your Critical Investment 🛡️**

Tooling is expensive. Servo presses treat it gently.

* **Minimized Impact:** Controlled acceleration and deceleration mean the ram doesn't slam into the die or material. Reduced shock loading dramatically decreases stress fractures and wear on punches, dies, and guide systems.

* **Optimized Forming Speeds:** Forming materials at their ideal speed (often slower than traditional press speeds) reduces galling and heat generation, further extending tool life.

* **Overload Prevention:** Real-time force monitoring can detect anomalies and stop the press before catastrophic tool damage occurs. This means fewer unexpected tool failures, lower maintenance costs, and longer intervals between costly tool refurbishments or replacements.

5. **Energy Efficiency: Powering Productivity Responsibly 🌱**

Forget the constant roar of a flywheel motor running full-tilt even when idle. Servo presses only consume significant energy when the motor is actively moving the ram. During dwell times or pauses, energy draw plummets. Regenerative drives capture the energy generated when the ram decelerates and feeds it back into the system. The result? Energy savings of 20%, 30%, sometimes even 50% or more compared to equivalent mechanical presses. In an era of rising energy costs and sustainability mandates, this isn't just good economics; it's a competitive necessity and a badge of environmental responsibility.

6. **Quieter Operation \u0026 Improved Ergonomics 🤫**

The difference is startling. Servo presses are significantly quieter than their mechanical counterparts. The absence of the relentless flywheel whine, the crash of the clutch engagement, and the bang of the ram hitting bottom creates a much calmer, less fatiguing work environment. Reduced noise pollution improves communication, enhances safety (hearing alarms is easier), and contributes to better operator morale and focus. It’s simply a more pleasant place to work.

7. **Smarter Manufacturing: Data \u0026 Connectivity 📊**

Servo presses are inherently digital machines. They generate a wealth of operational data – cycle time, stroke count, energy consumption, tonnage curves, error logs. This data can be captured via onboard PLCs and integrated into factory networks and MES (Manufacturing Execution Systems). Imagine:

* Real-time monitoring of press performance and OEE (Overall Equipment Effectiveness).

* Predictive maintenance alerts based on performance trends, not just failure.

* Detailed production reporting for traceability and process optimization.

* Remote diagnostics and support.

This data transforms the press from a standalone machine into an intelligent node in a connected, smart factory ecosystem.

**Real-World Symphony: Where Servo Presses Dominate**

The theory is impressive, but where does the rubber meet the road (or rather, the metal meet the die)?

* **Automotive Excellence 🚗:** From intricate transmission components requiring absolute precision to large body panels demanding perfect form and surface finish, servo presses are the workhorses of modern automotive manufacturing. Forming high-strength steels (HSS) and ultra-high-strength steels (UHSS), notorious for springback, becomes manageable with controlled speed and dwell. Deep drawing fuel tanks or complex structural parts achieves new levels of consistency. Reduced scrap on high-volume parts? Massive cost savings.

* **Aerospace \u0026 Defense Soaring Higher ✈️:** Where titanium, inconel, and complex aluminum alloys demand absolute precision and minimal material stress, servo presses deliver. Forming critical engine components, structural brackets, or intricate housings with tight tolerances and perfect repeatability is non-negotiable. The ability to control forming speed prevents cracking in sensitive alloys.

* **Electronics: Tiny Parts, Massive Precision 📱:** Forming delicate contacts, intricate shielding cans, or small connectors requires a feather touch and micron-level accuracy. Servo presses excel, minimizing distortion and damage to sensitive components. The programmable \"soft touch\" approach and precise positioning are invaluable.

* **Medical Device Manufacturing: Life-Saving Precision ❤️⚕️:** Surgical instruments, implant components, and diagnostic device parts demand absolute sterility, biocompatibility, and flawless geometry. Servo presses ensure consistent forming of specialized stainless steels and titanium alloys, with clean room compatibility often enhanced by their quieter, cleaner operation (reduced oil mist compared to hydraulics).

* **Appliance \u0026 General Metal Fabrication:** Even beyond these high-tech sectors, the benefits resonate. Creating perfectly formed hinges, brackets, housings, and decorative elements with lower scrap, longer tool life, and greater flexibility makes servo technology a compelling upgrade for any serious metal former looking to compete.

**The Human Element: Beyond the Machine 🤝**

Adopting servo technology isn't just about buying a new machine; it's about embracing a smarter way to work. Yes, there's a learning curve. Operators transition from simply loading parts and pulling a lever to understanding how different speed profiles and dwell times affect the forming process. Set-up personnel become programmers, leveraging the machine's flexibility. Maintenance teams deal more with sophisticated electronics and software than worn clutches and brakes. This shift requires investment in training and a change in mindset.

But the rewards are immense. Engineers are liberated to design better parts, knowing the press can achieve the required precision. Production planners gain unprecedented scheduling flexibility – quick changeovers mean smaller batches become economical. Quality managers see defect rates plummet. CFOs appreciate the combined savings from scrap reduction, energy efficiency, and extended tool life. Operators work in a cleaner, quieter, safer environment. It elevates the entire production ecosystem.

**Addressing the Elephant in the Room: Investment \u0026 ROI 💸**

Let's be candid: the initial capital expenditure for a servo motor press is typically higher than a comparable mechanical press. This upfront cost can be daunting. However, focusing solely on the sticker price is a short-sighted view that ignores the Total Cost of Ownership (TCO) and the powerful Return on Investment (ROI) potential.

* **Crushing the Cost of Scrap:** This is often the fastest payback. Reducing scrap by 30%, 50%, or more translates directly into saved material costs – often the largest cost component in metal forming. For high-volume or high-value parts, this saving alone can justify the investment within a surprisingly short timeframe.

* **Tooling Longevity = Capital Preservation:** Doubling or tripling tool life means spending far less on replacement tooling and the downtime associated with changing out worn or broken tools. This significantly reduces the ongoing operational cost burden.

* **Energy Bills in Retreat:** Slashing energy consumption by 20-50% is a continuous saving that compounds year after year, especially important with volatile energy prices.

* **Uptime \u0026 Productivity Gains:** Faster setups, fewer crashes (thanks to overload protection), reduced downtime for tool changes and maintenance all contribute to higher machine utilization and overall throughput. More good parts out the door per shift.

* **Quality Premium:** Higher, more consistent quality can command premium pricing, reduce warranty claims, and strengthen your brand reputation, opening doors to more demanding customers.

A thorough ROI analysis that quantifies these factors often reveals a payback period well within acceptable industrial investment horizons. Servo technology isn't an expense; it's a strategic investment in competitiveness, efficiency, and future-proofing your manufacturing capability.

**Choosing Your Champion: Key Considerations**

Not all servo presses are created equal. When evaluating, look beyond the basic specs:

* **Drive Mechanism:** Ball screw vs. Link Drive vs. Direct Drive. Each has pros and cons regarding speed, force, stroke length, and maintenance. Understand which best suits your primary applications.

* **Control System \u0026 Software:** This is the brain. Is the interface intuitive for operators and programmers? How sophisticated are the motion profiling capabilities? What data logging and connectivity options are available? Look for open architectures for future integration.

* **Tonnage \u0026 Stroke:** Ensure it matches your current and anticipated future needs. Remember the flexibility allows one press to handle a wider range of jobs than a mechanical equivalent.

* **Force Monitoring:** Is accurate, real-time tonnage monitoring and control included? This is critical for process control and protection.

* **Build Quality \u0026 Support:** Reputation matters. Investigate the manufacturer's track record, quality of construction (frame rigidity is crucial!), and the strength of their local service and technical support network. Downtime is costly.

**The Future is Programmable 🔮**

The servo motor press is more than just the latest press technology; it represents a fundamental shift towards intelligent, flexible, and sustainable manufacturing. It replaces brute force with programmed precision, waste with efficiency, and rigid processes with adaptable solutions.

For companies clinging to the *thud-thud-thud* of yesterday, the future is getting louder in all the wrong ways – the noise of inefficiency, scrap piling up, and competitors pulling ahead. For those embracing the near-silent hum of the servo press, the future sounds like precision, profit, and the quiet confidence of manufacturing excellence.

It’s not just about making parts. It’s about making perfect parts, consistently, efficiently, and intelligently. hysteresis brakes ’s about unleashing new design possibilities. It’s about securing your place in the competitive landscape of tomorrow, today. The revolution isn't coming; it's already here, reshaping metal, redefining quality, and rewriting the rules of manufacturing, one perfectly controlled stroke at a time. 🤖🎯🏆