Exactly how to Pick the Right Scaffolding for Your Building And Construction Job

The Makeup of a Scaffold: Understanding Its Elements

To understand the anatomy of a scaffold, concentrate on its essential features like offering security for workers at varied elevations and making sure job effectiveness. Parts consist of steel, aluminum, or timber products designed for safety and security and stability. Scaffold frameworks can be found in numerous types and materials, with adjustable heights and cross-bracing for assistance. Platforms are vital for employee safety and security, needing correct weight distribution and safe and secure accessory. Precaution involve cautious examination, safe base plates, guardrails, and routine checks. Discovering these facets better boosts knowledge of scaffold building and construction and safety treatments.

Trick Functions of a Scaffold

What necessary functions does a scaffold play in numerous building and construction projects?

The features of a scaffold are important in giving a safe and reliable working environment for building and construction workers. The structure of a scaffold is made to support workers, products, and devices at raised elevations throughout building, maintenance, or repair work jobs. Safety is a key worry when it involves scaffolding, and laws are in place to guarantee that scaffolds are put up, utilized, and took apart effectively to avoid accidents and injuries.

One crucial function of a scaffold is to offer a steady system for workers to perform tasks at different elevations. The structure of the scaffold must be sturdy and safe and secure to support the weight of employees and materials. Furthermore, scaffolds enable workers to access hard-to-reach areas of a structure or structure safely. By complying with safety and security laws and standards, such as making use of correct autumn protection tools and inspecting the scaffold frequently, construction tasks can be completed successfully and without cases.

Key Parts of a Scaffold

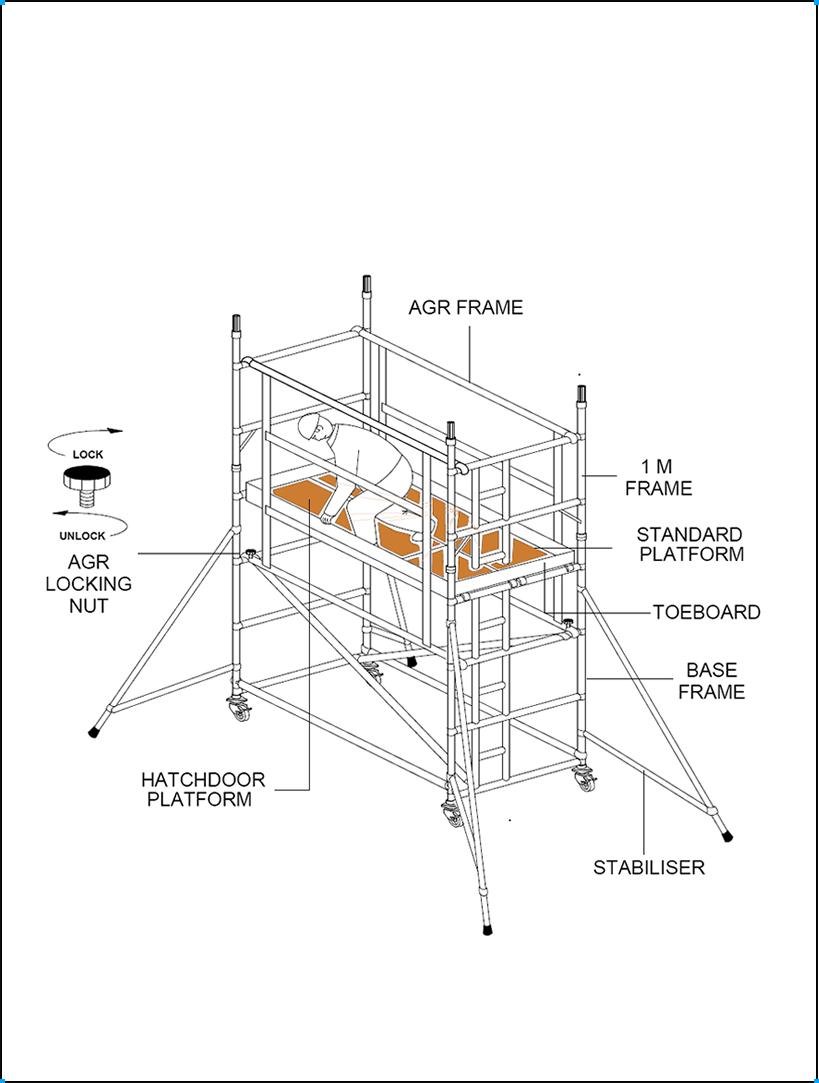

Scaffolds contain several main parts that are vital for assuring the security and safety and security of raised job systems in building and construction projects. The main elements of a scaffold consist of scaffold materials and scaffold layout. Scaffold products vary based on the requirements of the building and construction job and can consist of steel, light weight aluminum, timber, or a combination of these products. The scaffold design encompasses the format and structure of the scaffold, ensuring it can support the desired load securely.

The option of scaffold products is essential in identifying the stamina, durability, and overall security of the scaffold. Steel scaffolds are understood for their toughness and capacity to support heavy loads, making them suitable for large construction jobs. Light weight aluminum scaffolds, on the various other hand, are lightweight yet long lasting, making them excellent for projects that need constant repositioning. Wood scaffolds are commonly used for smaller projects due to their cost-effectiveness.

In scaffold layout, variables such as the scaffold's elevation, weight ability, and arrangement are carefully thought about to satisfy safety laws and project requirements. Proper scaffold layout is vital to stop accidents and make sure a safe workplace for construction workers.

Understanding Scaffold Frames

Understanding the structural framework of scaffold systems is crucial for guaranteeing stability and security on building websites. Scaffold frames play a crucial function in offering the necessary support for employees and products at different heights. To realize the idea better, consider the adhering to bottom line concerning scaffold frames:

- Sorts of Frames: Scaffold frames been available in numerous kinds such as walk-through structures, ladder frameworks, and stonework frames, each offering particular objectives on construction websites.

- Product Composition: Structures are typically built from steel or aluminum, supplying sturdiness and stamina to support the scaffold structure.

- Interlocking Mechanism: Many scaffold frameworks include an interlocking mechanism that enables simple setting up and disassembly, improving performance on-site.

- Flexible Levels: Some frame kinds use adjustable height setups, enabling workers to customize the scaffold to suit various project needs.

- Cross-Bracing for Security: Cross-bracing is frequently included into structure designs to enhance scaffold security and prevent guiding or tipping throughout use.

Understanding these elements of scaffold frameworks is necessary for making sure a risk-free and trusted working environment on building and construction projects.

Value of Scaffold Platforms

Analyzing the critical role of scaffold platforms in making certain structural integrity and safety at raised worksites is necessary for building and construction experts.

Scaffold platforms function as the important straight structures where workers stand, relocate, and carry out tasks. Platform stability is vital, as it directly affects the security of employees and the success of the building and construction job.

Appropriate weight distribution on scaffold platforms is critical to prevent overloading, which can result in platform failure and crashes. Ensuring that systems can support the intended tons ability is crucial in maintaining a safe workplace.

In addition, scaffold platforms should be securely attached to the scaffold framework to stop any type of activity or instability during usage. Construction specialists have to carefully evaluate scaffold systems prior to each usage to determine any indicators of damages or use that could jeopardize their security.

Precaution for Scaffold Setting Up

Taking into consideration the critical nature of scaffold stability and platform integrity, the implementation of strict precaution throughout scaffold assembly is vital to mitigate threats and guarantee a safe workplace. Following safety and security guidelines and making certain appropriate training are essential facets of scaffold assembly. Below are 5 key precaution to adhere to:

- Check Devices: Before assembly, completely take a look at all scaffold components for any damage or issues that can jeopardize safety.

- Protect Base Plates: Ensure that base plates are firmly placed on a solid surface to give security and prevent tipping.

- Use Guardrails: Install guardrails on all open sides and ends of the scaffold to avoid falls and improve worker safety and security. https://hampsteadscaffolding.co.uk https://hampsteadscaffolding.co.uk/index.html

- Effectively Planked Platforms: Scaffold platforms must be properly planked with materials capable of sustaining desired loads to stay clear of architectural failings.

- Routine Safety Checks: Conduct regular safety and security evaluations during setting up to determine and attend to any kind of safety and security dangers promptly.

Often Asked Questions

Exist Any Rules or Standards for the Optimum Elevation a Scaffold Can Be Constructed To?

Scaffold stability is vital in guaranteeing safety on construction websites. Height regulations dictate the optimum allowable elevation for scaffolds to maintain structural integrity. Safety safety measures, such as routine evaluations and adherence to standards, are essential, especially in extreme climate condition.

Can Scaffolds Be Used in Extreme Weather Conditions Such as Hefty Rainfall or Snow?

Scaffolds can be utilized in extreme weather with appropriate safety measures. Waterproofing strategies like covering with tarpaulins and securing joints can shield versus heavy rain. Winter preventative measures consist of utilizing non-slip surface areas and ensuring security in snow.

How Typically Should Scaffolds Be Evaluated for Deterioration or Damages?

Scaffolds should be checked regularly in accordance with safety requirements to assure structural integrity. Inspection regularity depends on use, with most laws advising weekly checks. Routine upkeep techniques are vital for recognizing deterioration or harm promptly.

Are There Any Details Weight Limits for Scaffolds to Guarantee Security?

Weight restrictions for scaffolds are necessary to guarantee safety and security on building and construction sites. Safety policies typically dictate details weight capacities for different sorts of scaffolding based on their layout and materials. Abiding by these restrictions is crucial.

What Are Some Usual Blunders or Errors to Avoid When Putting Together a Scaffold?

When creating a scaffold, essential errors to prevent include improper bracing, ignoring safe footing, making use of damaged parts, surpassing weight limits, and ignoring safety and security guidelines. Warranty detailed training, regular evaluations, and conformity with laws.

Final thought

To summarize, understanding the crucial functions and components of a scaffold, consisting of structures and systems, is essential for ensuring security throughout assembly.

By sticking to safety measures and standards, employees can effectively make use of scaffolds for numerous building projects.

It is critical to focus on the appropriate setting up and upkeep of scaffolds to avoid crashes and ensure a safe workplace.