Comprehending the Chemistry Behind Resin-Coated Aluminium Mixture

Polymer covered aluminium compound is become a crucial component in multiple sectors, especially in coatings, paint products, and ink solutions. This application is guided by the distinct characteristics that aluminium provides to a vast selection of items. Focusing on strength and aesthetic attractiveness, companies are progressively choosing this innovative resource that not only improves visual effects but also delivers vital defensive qualities.

A of the key merits of polymer covered aluminium compound is its ability to defend against corrosion and environmental wear. Such a feature makes it an outstanding choice for outdoor settings where exposure to the surroundings can lead to decline. The result is a rust-resistant silver pigment that preserves its integrity and aesthetic over time, providing long-lasting performance. Comprehending the science behind this extraordinary substance can create new possibilities for enhancing product longevity and efficiency across multiple applications.

Introduction to Resin Coated Aluminum Paste

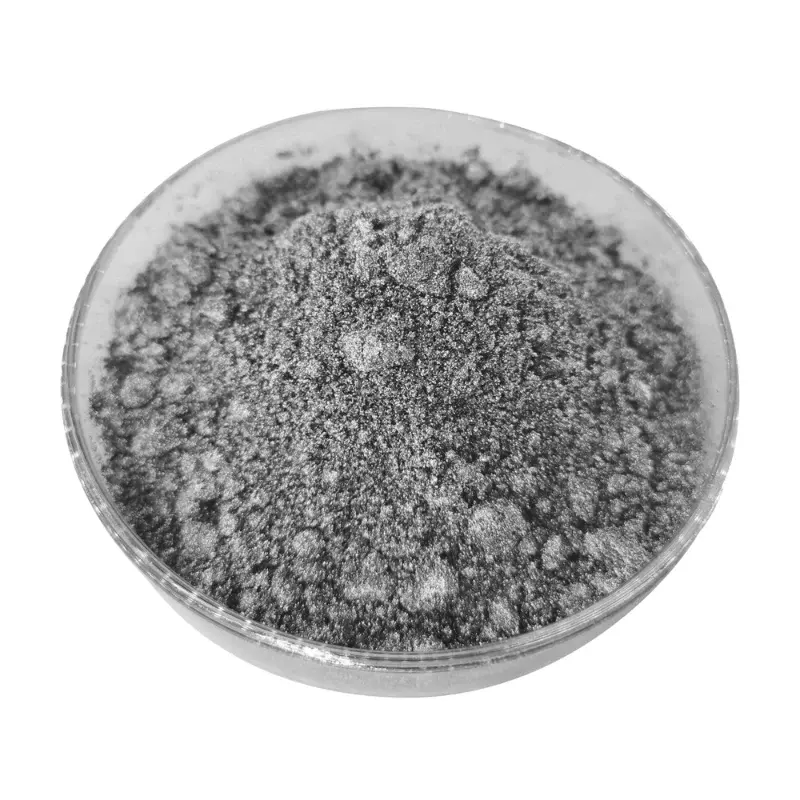

Coated with resin aluminum paste is a specialized material that has achieved notoriety in multiple industries due to its unique properties. It consists of aluminum particles covered with a resin, creating a product that combines the light and reflective nature of aluminum with the protective qualities of resin. This advanced formulation allows for implementations in coatings, inks, and plastics, providing a flexible solution for manufacturers.

One of the key features of resin coated aluminum paste is its corrosion resistance. The resin coating acts as a protective layer, preventing moisture and environmental factors from get to the aluminum substrate, which can lead to degradation over time. This feature is notably important in industries such as automotive and construction, where materials are frequently exposed to harsh conditions. https://www.boyanpigment.com/premium-resin-coated-aluminum-paste-for-metal-effect-coatings/ of anti-corrosion silver pigment enhances its robustness and aesthetic appeal, making it an excellent choice for high-performance applications.

Additionally, the weather-resistant aluminum paste offers exceptional performance in outdoor applications. The resin not only protects the aluminum but also ensures UV stability, allowing the material to retain its integrity and appearance even when faced with sunlight and changing weather conditions. This combination of properties ensures that products using resin coated aluminum paste remain attractive and functional over an extended time, meeting the demands of both manufacturers and consumers alike.

Features of Corrosion-Resistant Ag Colorant

Corrosion resistant silver dye is a vital component in multiple coatings and coating materials, providing both decorative qualities and operational features. One of the primary characteristics of this dye is its capability to create a barrier against moisture and detrimental external elements. By preventing the intrusion of liquids and damaging substances, it greatly enhances the longevity of the layers that contain it. This property makes it notably important in sectors where durability and defense to degradation are essential.

A further notable characteristic of corrosion resistant silver pigment is its superior opacity and reflective qualities. These features enable effective hiding of underlying surfaces while also improving the visual appeal of the final product. The significant reflectivity of the silver pigment contributes to energy-saving properties by reflecting warmth, making it an optimal choice for purposes in vehicle, aerospace, and building layers. This mix of performance and visual qualities plays a role to extending the lifespan of the coatings under multiple environments.

Additionally, this colorant shows notable stability under severe external factors. It withstands loss of color due to ultraviolet light, ensuring that the coatings retain their look over time. With its capability to endure extreme heat and chemical agents, corrosion resistant metallic silver pigment is often used in manufacturing applications where typical pigments may fail. This endurance not only enhances the protective qualities of the coatings but also minimizes the necessity for ongoing care and renewal.

Advantages of Weatherproof Aluminum Paste

Weather-resistant aluminum paste provides outstanding durability, rendering it perfect for outside applications. This type of paste is engineered to tolerate extreme environmental conditions, including high temperatures, UV radiation, and moisture. By integrating durable properties, coatings and paints that employ this paste are better equipped to combat degradation over time. This longevity means lower maintenance costs and prolonged life for the substrates treated with the paste.

Moreover significant benefit of weatherproof aluminum paste is its enhanced aesthetic appeal. The small aluminum particles provide a shiny metallic finish, improving the visual quality of products. This reflective quality merely adds to the appearance of the surface but also enhances its heat management by reflecting sunlight and ensuring surfaces cooler. As a consequence, it can help elevate the overall appeal of both architectural and industrial finishes.

Additionally, the use of weatherproof aluminum paste contributes to better corrosion resistance. By forming a protective layer over substrates, it helps to lessen the risk of corrosion that can be prompted by exposure to moisture and other environmental factors. This characteristic is particularly beneficial in applications where metal surfaces are vulnerable to rust and degradation, ensuring that products keep their integrity and performance for an extended period.

Applications in Various Industries

Aluminum paste coated with resin has found extensive use in the automotive industry, where it is utilized in coatings and finishes to provide both aesthetic appeal and practical benefits. The corrosion resistant silver pigment enhances the strength of coatings applied to vehicles, protecting them from harsh weather conditions. This application not only improves the look of the vehicles but also extends their service life by preventing damage from rust and other degradation factors.

In the building sector, resin coated aluminum paste is employed in multiple architectural applications. Its weather-resistant properties make it perfect for exterior coatings and finishes that are exposed to the elements. These coatings not only offer a protective shield but also contribute to energy efficiency by reflecting heat away from buildings, thus helping to control indoor temperatures and reducing energy consumption over time.

Additionally, the cosmetic industry leverages the unique qualities of resin coated aluminum paste in formulations for makeup products. The aesthetic appeal provided by the shine and metallic finish helps enhance cosmetic formulations, making them more visually appealing to buyers. Moreover, its stability and resistance to degradation ensure that these products maintain their quality over time, making them a preferred choice in the formulation of high-performance cosmetics.