The Essential Guide to Power Cables for Robotics

Introduction

In the realm of robotics, power cables play a crucial role in ensuring the efficient and reliable operation of robotic systems. These cables are responsible for delivering power from a source to the various components of a robot, enabling it to move, sense its environment, and carry out its programmed tasks. In this comprehensive guide, we will delve into the world of power cables for robotics, exploring their key characteristics, types, design considerations, and best practices for selection and maintenance.

Importance of Power Cables in Robotics

Power cables are the lifelines of robotic systems, as they serve as the primary means of transmitting electrical power to the motors, sensors, actuators, and other components of a robot. Without a reliable and efficient power supply, a robot would be rendered inoperable, unable to perform its intended functions. Therefore, selecting the right power cables for a robotic application is crucial to ensuring optimal performance, safety, and longevity of the system.

Key Characteristics of Power Cables for Robotics

When it comes to selecting power cables for robotics, several key characteristics must be taken into consideration to meet the specific requirements of the application. These characteristics include:

1. Voltage Rating: The voltage rating of a power cable indicates the maximum voltage that the cable can safely handle. It is essential to select a power cable with a voltage rating that is compatible with the voltage of the power source and the components of the robotic system.

2. Current Capacity: The current capacity of a power cable refers to the maximum current that the cable can carry without overheating or sustaining damage. It is crucial to choose a power cable with an adequate current capacity to meet the power requirements of the robotic system.

3. Flexibility: In robotics applications, power cables are often required to bend and move along with the robotic arm or other moving parts. Therefore, flexibility is a critical characteristic of power cables for robotics to ensure easy installation and reliable operation.

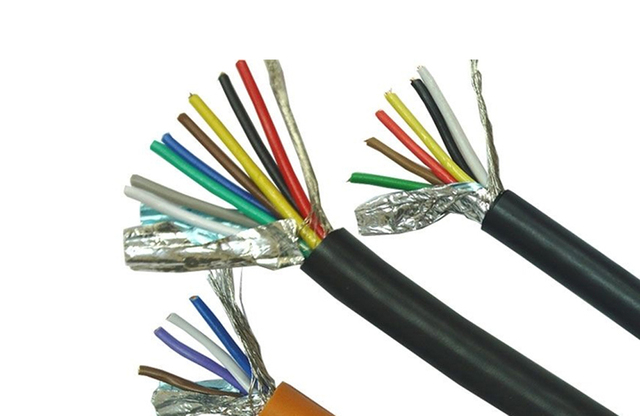

4. Shielding: Shielding is essential to protect power cables from electromagnetic interference (EMI) and radio frequency interference (RFI) that can affect the performance of the robotic system. Shielded power cables are recommended for applications where EMI and RFI are prevalent.

5. Temperature Rating: The temperature rating of a power cable indicates the range of temperatures at which the cable can safely operate. It is important to select a power cable with a temperature rating that is suitable for the environmental conditions in which the robotic system will be operating.

Types of Power Cables for Robotics

Power cables for robotics come in various types and configurations to meet the diverse needs of different robotic applications. Some of the common types of power cables used in robotics include:

1. PVC Power Cables: PVC (polyvinyl chloride) power cables are a popular choice for robotics applications due to their flexibility, durability, and cost-effectiveness. insulated sheathed power cable are suitable for indoor robotic applications where exposure to harsh environmental conditions is minimal.

2. Silicone Power Cables: Silicone power cables are known for their high flexibility, temperature resistance, and resistance to chemicals and oils. These cables are ideal for robotic applications that require flexibility and resistance to extreme temperatures.

3. Teflon Power Cables: Teflon power cables are known for their excellent resistance to high temperatures, chemicals, and abrasion. These cables are commonly used in high-temperature robotic applications where durability and reliability are paramount.

4. Shielded Power Cables: Shielded power cables are designed with an additional layer of shielding to protect against EMI and RFI. These cables are ideal for robotic applications where electromagnetic interference is a concern.

Design Considerations for Power Cables in Robotics

When designing a robotic system, several considerations must be taken into account to ensure the proper selection and installation of power cables. Some of the key design considerations for power cables in robotics include:

1. Cable Routing: Proper cable routing is essential to prevent cable fatigue, tangling, or damage during the operation of the robotic system. Careful planning of cable paths and securing of cables can help minimize the risk of cable failure.

2. Cable Length: The length of the power cables should be carefully calculated to ensure that they reach all the components of the robotic system without excessive slack or tension. Proper cable length can help prevent strain on the cables and ensure optimal performance.

3. Connector Compatibility: When selecting power cables for robotics, it is important to consider the compatibility of the connectors with the components of the robotic system. Using connectors that are compatible with the power source and the components can help ensure a secure and reliable connection.

4. Environmental Conditions: The environmental conditions in which the robotic system will be operating should be taken into account when selecting power cables. Factors such as temperature, humidity, exposure to chemicals, and mechanical stress can impact the performance and lifespan of the cables.

Best Practices for Selection and Maintenance of Power Cables

To ensure the optimal performance and longevity of power cables in robotics applications, following best practices for selection and maintenance is essential. Some of the best practices for selecting and maintaining power cables for robotics include:

1. Conduct a thorough assessment of the power requirements of the robotic system to determine the voltage, current, and other specifications needed for the power cables.

2. Choose power cables with appropriate voltage ratings, current capacities, flexibility, shielding, and temperature ratings to meet the specific requirements of the application.

3. Inspect power cables regularly for signs of wear, damage, or degradation, and replace any cables that show signs of deterioration to prevent potential failures.

4. Properly route and secure power cables to prevent strain, kinking, or entanglement during the operation of the robotic system.

5. Follow manufacturer recommendations for installation, handling, and maintenance of power cables to ensure safe and reliable operation of the robotic system.

Conclusion

Power cables are an essential component of robotic systems, providing the necessary electrical power to drive the motors, sensors, actuators, and other components of a robot. Selecting the right power cables for a robotics application is crucial to ensuring optimal performance, safety, and reliability of the system. By considering key characteristics, types, design considerations, and best practices for selection and maintenance of power cables, robotic engineers and enthusiasts can enhance the efficiency and longevity of their robotic creations.