Performance Analysis of Diesel Generators A Comprehensive Guide

Introduction

Diesel generators play a crucial role in providing backup power during electrical outages or in areas where the grid is unreliable. These generators are commonly used in various industries, commercial buildings, hospitals, and residential settings to ensure continuous power supply. The performance analysis of diesel generators is essential to ensure their efficient operation, reliability, and cost-effectiveness. In this article, we will discuss the key aspects of performance analysis for diesel generators, including their components, working principle, testing methods, and maintenance practices.

Components of a Diesel Generator

A diesel generator consists of several key components that work together to generate electricity. 200kw diesel generator for remote research facilities of a diesel generator include:

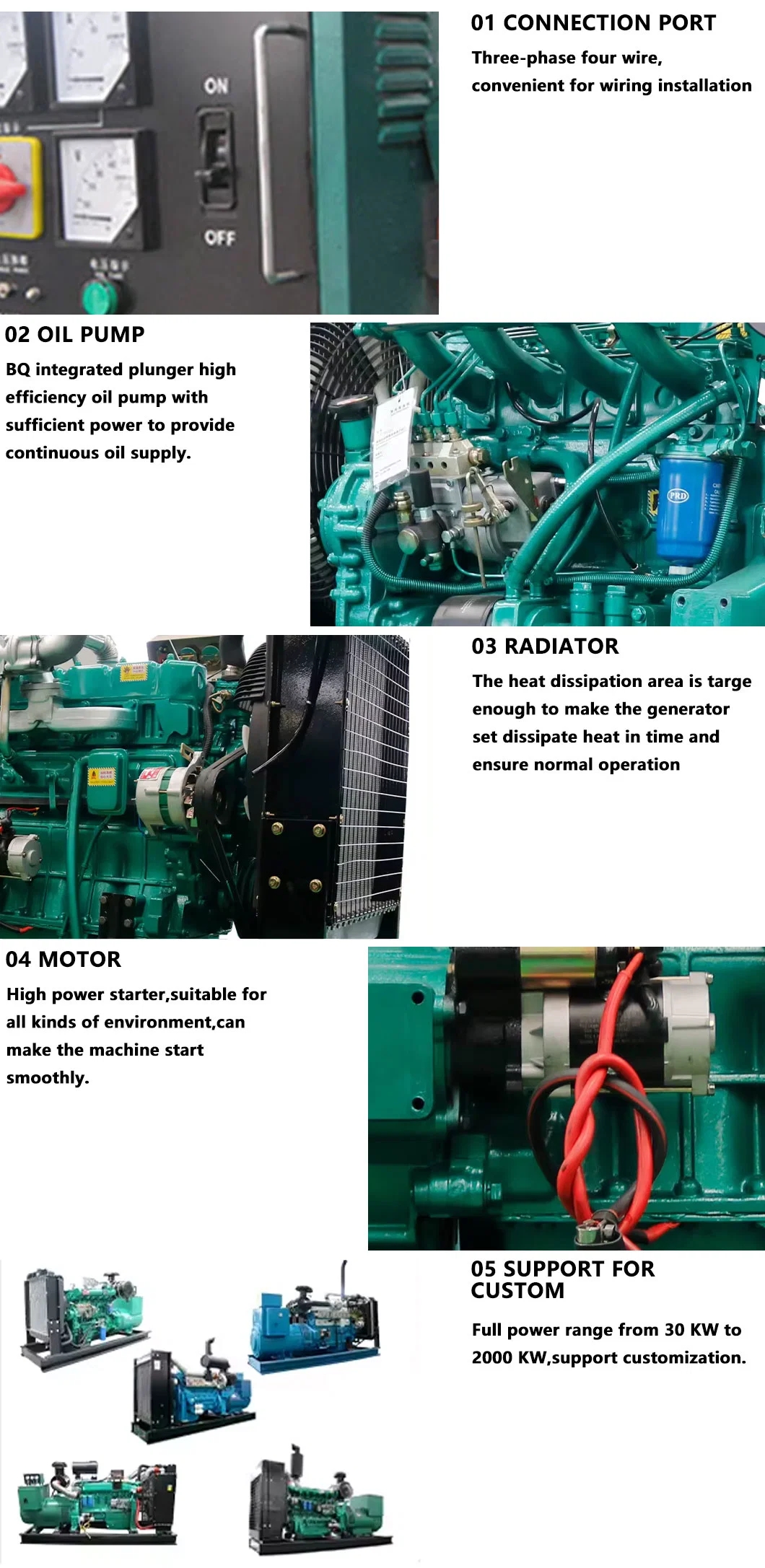

1. Engine: The engine is the heart of a diesel generator, responsible for converting diesel fuel into mechanical energy. Diesel engines are known for their durability, efficiency, and reliability, making them ideal for generator applications.

2. Alternator: The alternator is connected to the engine and generates electricity by converting the mechanical energy produced by the engine into electrical energy. The alternator plays a critical role in determining the output voltage and frequency of the generator.

3. Fuel System: The fuel system supplies diesel fuel to the engine for combustion. It includes a fuel tank, fuel pump, fuel filter, and fuel injectors. Proper maintenance of the fuel system is essential for the efficient operation of the generator.

4. Cooling System: The cooling system helps regulate the temperature of the engine to prevent overheating. It typically includes a radiator, cooling fan, water pump, and coolant. Adequate cooling is necessary to ensure the longevity of the engine.

5. Exhaust System: The exhaust system is responsible for removing the combustion gases from the engine and reducing noise levels. It includes a muffler and exhaust pipes that direct the exhaust gases outside the generator enclosure.

6. Control Panel: The control panel serves as the brain of the generator, allowing users to start, stop, and monitor the generator. It provides essential information such as voltage, current, frequency, and engine status.

Working Principle of a Diesel Generator

The working principle of a diesel generator involves the conversion of diesel fuel into mechanical energy and then into electrical energy. The process can be summarized in the following steps:

1. Fuel Injection: The diesel fuel is injected into the combustion chamber of the engine, where it mixes with compressed air.

2. Compression: The air-fuel mixture is compressed by the pistons in the engine cylinder, leading to a significant increase in temperature and pressure.

3. Combustion: The compressed air-fuel mixture is ignited by the heat generated during compression, causing the fuel to burn rapidly and produce high-pressure gases.

4. Mechanical Energy Conversion: The high-pressure gases push the pistons down, converting the chemical energy of the fuel into mechanical energy.

5. Electrical Energy Generation: The mechanical energy produced by the engine is transferred to the alternator, where it is converted into electrical energy through electromagnetic induction.

6. Voltage Regulation: The alternator regulates the output voltage to maintain a stable electrical supply within the desired range.

Performance Analysis of Diesel Generators

Performance analysis of diesel generators involves evaluating various parameters to assess their efficiency, reliability, and overall performance. The key parameters that are typically analyzed include:

1. Power Output: The power output of a diesel generator is measured in kilowatts (kW) and indicates the amount of electrical power that the generator can supply. It is essential to ensure that the generator's power output meets the requirements of the load it is intended to support.

2. Voltage Regulation: Voltage regulation refers to the ability of the generator to maintain a stable output voltage under varying load conditions. Poor voltage regulation can lead to voltage fluctuations that may damage sensitive electrical equipment.

3. Frequency Stability: The frequency of the electrical output is measured in Hertz (Hz) and should remain stable within a certain range (e.g., 50 Hz or 60 Hz) to prevent damage to connected devices.

4. Fuel Efficiency: Fuel efficiency is a critical factor in determining the operating cost of a diesel generator. Analyzing the fuel consumption rate and efficiency can help optimize the generator's performance and reduce overall fuel expenses.

5. Load Testing: Load testing involves subjecting the generator to varying load conditions to assess its performance under different scenarios. This helps identify potential issues such as voltage drops, frequency fluctuations, or overheating.

6. Emissions Compliance: Diesel generators produce exhaust emissions that can have environmental impacts. Monitoring and analyzing emissions levels can ensure compliance with regulatory standards and reduce the generator's environmental footprint.

Testing Methods for Performance Analysis

Several testing methods can be used to analyze the performance of diesel generators and identify any issues that may affect their operation. Some common testing methods include:

1. Load Bank Testing: Load bank testing involves connecting a load bank to the generator to simulate varying load conditions. This test helps evaluate the generator's performance under different loads and assess its ability to maintain voltage and frequency stability.

2. Fuel Consumption Testing: Fuel consumption testing measures the amount of fuel consumed by the generator over a specific period. By analyzing fuel consumption rates, operators can optimize fuel efficiency and reduce operating costs.

3. Emissions Testing: Emissions testing measures the levels of pollutants emitted by the generator, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. Monitoring emissions levels is essential for environmental compliance and sustainability.

4. Thermal Imaging: Thermal imaging involves using infrared cameras to detect hotspots or overheating components in the generator. This non-invasive testing method can identify potential issues before they lead to equipment failure.

5. Performance Monitoring: Continuous performance monitoring involves tracking key parameters such as voltage, current, frequency, and temperature in real-time. Monitoring software can provide insights into the generator's operation and alert operators to any abnormalities.

Maintenance Practices for Diesel Generators

Proper maintenance is essential to ensure the reliable performance of diesel generators and extend their lifespan. Some essential maintenance practices for diesel generators include:

1. Regular Inspections: Conducting routine inspections of the generator's components, including the engine, alternator, fuel system, cooling system, and exhaust system, can help identify potential issues early and prevent costly repairs.

2. Oil and Filter Changes: Regular oil changes and filter replacements are critical to maintaining the engine's lubrication and preventing premature wear. Follow the manufacturer's recommendations for oil type and change intervals.

3. Cooling System Maintenance: Inspecting the cooling system for leaks, checking coolant levels, and cleaning the radiator and cooling fan are essential maintenance tasks to prevent overheating and engine damage.

4. Battery Care: Proper battery maintenance, including checking the electrolyte levels, cleaning terminals, and ensuring a full charge, is crucial for reliable generator starting.

5. Fuel System Inspection: Regularly inspecting the fuel system for leaks, clogs, and contamination can prevent fuel-related issues that may affect the generator's performance.

6. Testing and Calibration: Periodic testing and calibration of the generator's control panel, voltage regulator, and other critical components can ensure accurate operation and reliable performance.

Conclusion

Diesel generators are essential for providing backup power in various applications, and their performance analysis is crucial to ensure their efficient operation and reliability. By evaluating key parameters such as power output, voltage regulation, frequency stability, fuel efficiency, and emissions compliance, operators can optimize the performance of diesel generators and reduce operating costs. Implementing proper testing methods, maintenance practices, and monitoring strategies can help maximize the lifespan and effectiveness of diesel generators in supporting critical power needs.