Shielded Cable Ensuring Reliable Protection for Sensitive Equipment

Introduction

In today's increasingly digital world, sensitive electronic equipment is ubiquitous, playing a crucial role in various industries, from telecommunications to healthcare to aerospace. This equipment is vulnerable to electromagnetic interference (EMI) and radiofrequency interference (RFI), which can lead to malfunctions, data corruption, and signal degradation. To safeguard these sensitive devices and ensure their optimal performance, shielded cables are essential. Shielded cables provide a protective barrier against external interferences, thereby enhancing the reliability and longevity of the connected equipment. In this article, we will explore the significance of shielded cables for sensitive equipment, their construction, types, applications, and benefits.

Why Shielded Cables are Essential for Sensitive Equipment

Sensitive electronic equipment such as medical devices, industrial machinery, and communication systems are susceptible to EMI and RFI, which can emanate from various sources, including power lines, motors, radio transmitters, and other electronic devices. These interferences can disrupt the normal operation of the equipment, leading to malfunctions, data errors, and even complete system failure. Shielded cables act as a protective shield, enclosing the conductors within a layer of conductive material that deflects or absorbs external electromagnetic disturbances, preventing them from affecting the signal transmission. By using shielded cables, the integrity and performance of sensitive equipment can be maintained, ensuring reliable operation in the presence of electromagnetic interferences.

Construction of Shielded Cables

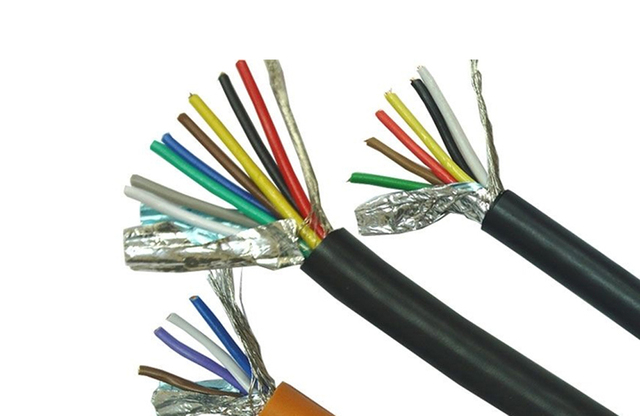

Shielded cables are designed with specific construction features that provide protection against EMI and RFI. The basic structure of a shielded cable consists of one or more insulated conductors surrounded by a metallic shield and an outer jacket. The key components of shielded cables are as follows:

1. Conductors: The conductors in shielded cables are typically made of copper or aluminum and are insulated with materials such as PVC, polyethylene, or Teflon. The insulation provides electrical separation between the conductors and ensures signal integrity.

2. Shield: The shield is a crucial component of shielded cables that provides protection against external interferences. The shield can be made of braided copper, aluminum foil, or a combination of both. The shield is connected to ground at one or both ends to dissipate any induced currents and prevent interference from reaching the conductors.

3. Jacket: The outer jacket of the shielded cable provides mechanical protection and insulation for the internal components. The jacket is typically made of PVC, polyethylene, or thermoplastic materials that offer durability and flexibility.

Types of Shielded Cables

There are several types of shielded cables available, each designed for specific applications and environments. The most common types of shielded cables include:

1. Foil Shielded Cable: Foil shielded cables consist of one or more conductors enclosed in a thin metallic foil, such as aluminum, that provides protection against EMI and RFI. Foil shields are lightweight and flexible, making them suitable for applications where space is limited.

2. https://www.jiangyuancables.com/xlpe-insulated-sheathed-power-cable/ Shielded Cable: Braided shielded cables feature a woven mesh of copper or aluminum strands that surround the conductors. Braided shields offer high flexibility and excellent protection against electromagnetic interferences, making them ideal for high-frequency applications.

3. Combination Shielded Cable: Combination shielded cables combine both foil and braided shields to provide enhanced protection against a wide range of interferences. These cables offer superior shielding effectiveness and are commonly used in critical applications where high reliability is required.

Applications of Shielded Cables

Shielded cables are widely used in various industries and applications where the protection of sensitive equipment is paramount. Some common applications of shielded cables include:

1. Data Transmission: Shielded cables are essential for data transmission applications, such as Ethernet networks, telecommunication systems, and audio/video equipment. By using shielded cables, data integrity and signal quality can be maintained, ensuring reliable communication.

2. Medical Devices: Medical equipment, such as MRI machines, patient monitors, and diagnostic devices, rely on shielded cables to prevent interference from external sources that could compromise patient safety and diagnostic accuracy.

3. Industrial Automation: In industrial automation systems, shielded cables are used to connect sensors, actuators, and control devices, ensuring uninterrupted operation in electromagnetic environments such as manufacturing plants and robotic applications.

4. Aerospace and Defense: Shielded cables are critical in aerospace and defense applications, where equipment must withstand extreme conditions and electromagnetic disturbances. Military communications systems, radar systems, and avionics rely on shielded cables for reliable performance.

Benefits of Shielded Cables

The use of shielded cables offers a wide range of benefits for sensitive equipment and critical applications. Some key benefits of shielded cables include:

1. EMI/RFI Protection: Shielded cables provide effective protection against electromagnetic and radiofrequency interferences, ensuring the reliable operation of sensitive equipment in electrically noisy environments.

2. Signal Integrity: By reducing the impact of external interferences, shielded cables help maintain signal integrity and minimize data errors, resulting in improved performance and accuracy of the connected equipment.

3. Noise Immunity: Shielded cables help mitigate noise and crosstalk, which can degrade signal quality and affect the overall performance of electronic systems. This noise immunity is essential for maintaining high-speed communication and data transmission.

4. Durability and Reliability: Shielded cables are designed to withstand harsh environmental conditions, mechanical stress, and electromagnetic disturbances, ensuring long-term reliability and durability in demanding applications.

5. Compliance with Industry Standards: Shielded cables are designed and manufactured in compliance with industry standards and regulations, ensuring compatibility and interoperability with a wide range of equipment and systems.

Conclusion

Shielded cables play a vital role in protecting sensitive equipment from electromagnetic interferences and ensuring reliable operation in challenging environments. By providing effective EMI/RFI protection, maintaining signal integrity, and offering noise immunity, shielded cables help safeguard critical applications in industries such as telecommunications, healthcare, aerospace, and industrial automation. Understanding the construction, types, applications, and benefits of shielded cables is essential for selecting the right cable solution to meet the specific requirements of sensitive equipment. By choosing shielded cables, organizations can enhance the performance, longevity, and security of their electronic systems, contributing to overall operational efficiency and reliability.