Finest Practices for Effective Motor Management

The Importance of Motor Management

In today's commercial landscape, motors play a pivotal role in powering various makers and processes. From making facilities to HVAC systems, motors are the workhorses that keep things running efficiently. However, handling these vital possessions effectively is often ignored. In this short article, we will delve into the best practices for motor management that can assist companies boost dependability, lower downtime, and enhance energy consumption.

Regular Maintenance and Inspection

Regular upkeep and assessments are the foundation of reliable motor management. Neglecting this aspect can lead to unforeseen breakdowns and increased operational expenses. Develop a thorough maintenance schedule that includes cleansing, lubrication, and electrical checks. Routine assessments can discover early signs of wear and tear, enabling you to resolve concerns prior to they escalate.

Proper Lubrication

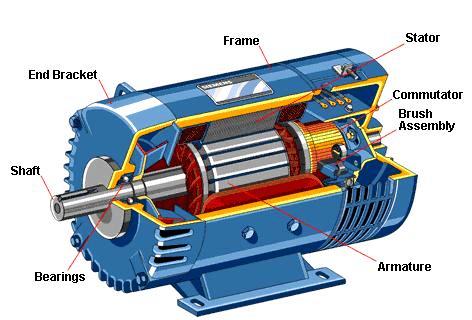

One of the most common causes of motor failure is inadequate lubrication. Motors rely on bearings and moving parts that need proper lubrication to minimize friction and heat. Establish a lubrication program that defines the type and frequency of lubrication, considering aspects such as operating conditions and ecological factors. Over-lubrication can be as harmful as under-lubrication, so follow producer recommendations carefully.

Vibration Analysis

Vibration analysis is a powerful predictive upkeep tool that can help identify motor issues prior to they become important. Purchase vibration tracking devices and develop a regular vibration analysis schedule. By keeping an eye on vibrations, you can find imbalances, misalignments, and bearing problems, enabling prompt restorative actions and preventing unforeseen breakdowns.

Electrical Testing

Electrical concerns are another leading reason for motor failures. Routinely check the motor's electrical elements, including insulation resistance, winding resistance, and present imbalance. These tests can discover potential problems like insulation breakdown or winding destruction. Attending to electrical concerns promptly can extend motor life and avoid security dangers.

Energy Efficiency Measures

In today's ecologically conscious world, optimizing energy consumption is a leading priority. Motors are typically the biggest customers of electrical energy in industrial settings. Carrying out energy-efficient practices not just minimizes operating costs however also decreases your organization's carbon footprint. Think about installing variable frequency drives (VFDs) to control motor speed based on demand, and guarantee motors are correctly sized for their designated tasks.

Documents and Asset Management

Precise record-keeping and property management are crucial for motor management. Produce a thorough database that includes motor requirements, upkeep history, and examination reports. This information enables you to track the efficiency of each motor and make data-driven choices. Modern property management software can simplify this process, making it simpler to keep track of and preserve your motor inventory.

Training and Skill Development

Buy training programs for your maintenance group to ensure they have the abilities and knowledge required to handle motors effectively. Supply them with the most recent market insights and finest practices. A trained group can identify issues early, lower downtime, and add to overall operational effectiveness.

Condition-Based Monitoring

Welcome technology to execute condition-based monitoring systems. These systems use sensing units and data analytics to continuously keep track of motor health. When abnormalities are detected, they activate informs, enabling instant attention. Condition-based tracking can substantially improve motor reliability by catching issues in their infancy.

Spare Parts Inventory

Maintaining a well-organized spare parts stock is essential for minimizing downtime. Recognize important spare parts for your motors and ensure you have a sufficient supply on hand. This proactive approach will assist you quickly address issues and reduce production disturbances. Click on https://metatec.net/electrical-preventative-maintenance-foundations-of-best-practice-motor-management/ to sketch out a map of truth about best practice motor management in your mind once and for all!

Conclusion: Effective motor management is not simply a matter of regular upkeep; it's a holistic technique that includes numerous elements, from routine inspections to energy effectiveness steps. By carrying out these finest practices, organizations can boost motor dependability, extend their lifespan, and decrease functional costs. Prioritizing motor management is an investment in productivity and sustainability that can yield significant returns in the long run.

Learn more:

https://reliabilityweb.com/articles/entry/7-ways-to-ensure-better-maintenance-of-electric-motors