Implementing Quality Control Measures in Wire Bonding Operations

Introduction

In the realm of electronics manufacturing, the wire bonding technique plays a pivotal function in organising dependableremember electrical connections among semiconductor chips and their substrates. As technological know-how advances, so does the complexity of twine bonding operations. This complexity necessitates rigorous pleasant control measures to ensure that operational effectivity, product reliability, and patron pleasure. This article delves into the intricacies of twine bonding generation, exploring the different innovations, machine, and programs whereas emphasizing the value of nice keep watch over.

What is Wire Bonding?

Wire bonding refers to a group of methods used to create electrical connections among semiconductor units by means of thin wires. These connections are a must-have for making sure that electronic resources objective as meant. The wire bonding means encompasses a number of processes such as ball bonding, wedge bonding, and ribbon bonding, each one with distinct blessings adapted to distinct purposes.

Types of Wire Bonding Techniques

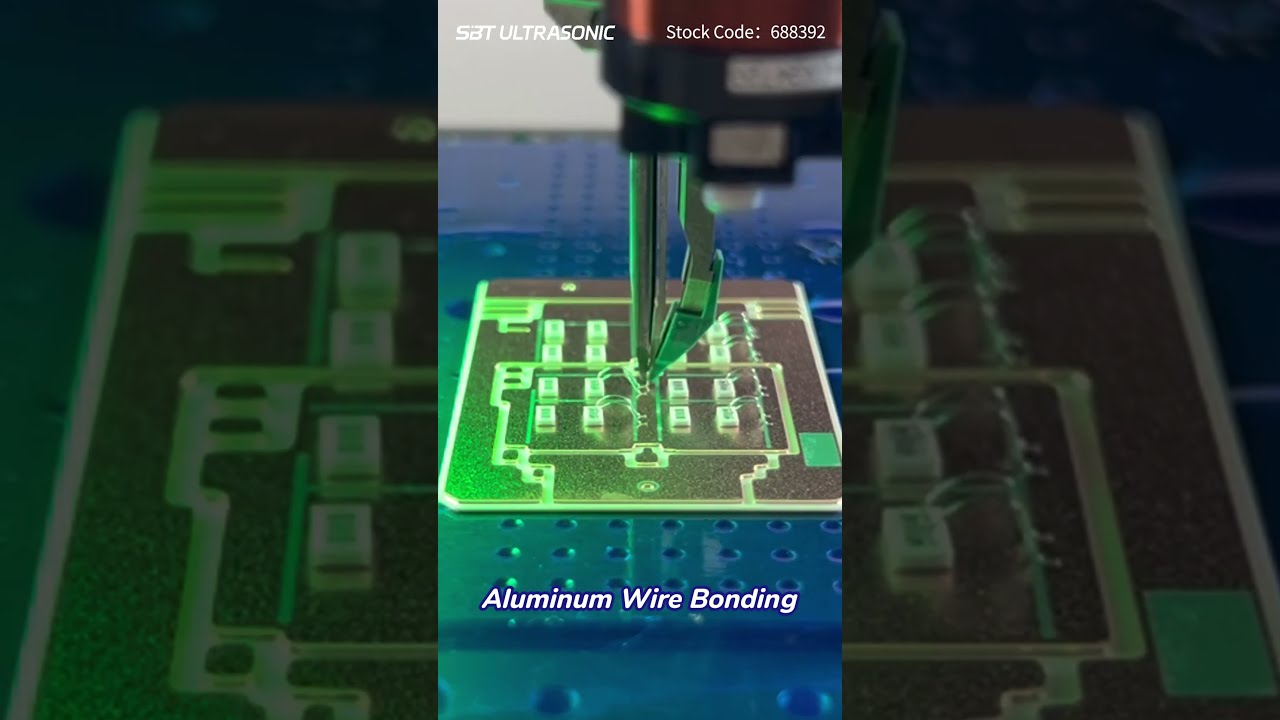

Ball Bonding Process: Involves creating a small ball on the give up of a wire with the aid of warmth and ultrasonic power sooner than attaching it to a bond pad. Applications: Commonly used for gold cord bonding in microelectronics. Wedge Bonding Process: Utilizes a wedge-formed software that presses the cord in opposition to the substrate. Applications: Effective for aluminum and copper wires in prime-frequency purposes. Ribbon Bonding Process: Employs flat ribbons instead of spherical wires to determine connections. Applications: Ideal for persistent modules owing to their multiplied surface section. Thermosonic Bonding Combines warmness and ultrasonic vigor to make stronger bond energy. Ultrasonic Bonding Uses ultrasonic vibrations without added warm for selected material. Deep Access Wedge Bonding Enables bonding in demanding-to-succeed in locations inside of problematical assemblies.

How Wire Bonding Works

The major Visit the website concept in the back of wire bonding contains utilising tension and warmth (or ultrasonic energy) to sign up for metals because of metallurgical interconnections. It begins with deciding on the best option bonding wires—more commonly gold, aluminum, or copper—depending on their conductivity and mechanical homes.

Wire Bonding Equipment Overview

Wire Bonding Machines

Modern twine bonding operations matter closely on really good machines adapted for the different varieties of bonds:

Manual Wire Bonding Machine: Designed for low-quantity production; calls for human operation.

Semi-Automatic Wire Bonder: Offers partial automation to enhance productiveness even as still requiring operator enter.

Fully Automatic Wire Bonder: Ideal for excessive-amount manufacturing; those machines can function independently with minimal supervision.

Bonding Tools

Each computing device is equipped with genuine tools designed for best functionality:

Bond Capillary Tool: Used to govern and situation the cord during bonding.

Wedge Bonder Tool: Essential for achieving accurate placements in wedge bonding methods.

Implementing Quality Control Measures in Wire Bonding Operations

Quality management plays a important function in making certain that wire bonds are authentic and meet business necessities. By enforcing systematic QC measures at some point of the twine bonding activity, producers can noticeably reduce defects and give a boost to product functionality.

Key Quality Control Techniques

Visual Inspection Regular inspections may still be conducted to establish any obvious defects comparable to bond lifting or incomplete bonds. Non-Destructive Testing (NDT) Techniques like X-ray inspection enable manufacturers to assess inner constructions without hazardous system. Pull Test Analysis Measures bond potential through utilising a drive unless failure happens; supports consider bond integrity. Shear Test Evaluation Similar to tug checks but focuses on horizontal shear forces acting on the bond interface. Environmental Controls Maintaining controlled temperature and humidity phases in the time of manufacturing can ward off oxidation-associated screw ups. Calibration Procedures Regular calibration of machines ensures constant overall performance across diverse batches of products. Documentation Standards Keeping thorough information of each batch's parameters allows for tracking returned any defects or things that occur post-manufacturing. Training Programs Continuous training programs for operators about highest quality practices in first-class guarantee help mitigate human blunders at some stage in operations. Supplier Quality Assurance Establish partnerships with safe suppliers who adhere to strict material excellent criteria reduces risks linked to inferior components.

FAQs

FAQ 1: What are original problems encountered in wire bonding?

Common topics encompass bond lifting, heel cracks, oxidation of bond pads, incomplete bonds, and infection for the period of production processes.

FAQ 2: How do you check if a bond is powerful satisfactory?

Bond force may be evaluated the use of pull checks or shear exams in which managed forces are utilized unless failure occurs; outcome point out even if bonds meet required requirements.

FAQ three: What supplies are almost always used for wire bonds?

Gold, aluminum, copper, and silver are probably used parts as a consequence of their most excellent conductivity homes; selection frequently relies on software necessities like thermal control or price concerns.

FAQ four: Why is environmental keep an eye on substantive in cord bonding?

Proper environmental controls lend a hand mitigate disadvantages linked to moisture absorption and oxidation that might compromise bond integrity through the years; that is fairly integral when operating with touchy parts like MEMS or RF modules.

FAQ five: Can I operate guide inspections readily?

Yes! However, relying fullyyt on visual inspection could introduce variability by using human errors; incorporating automated inspection methods complements accuracy severely at the same time as presenting function checks over timeframes worthwhile for top volume operations.

FAQ 6: What working towards supplies are available for studying approximately cord bonding?

Numerous online guides exist masking all the things from standard ideas of how wire bonding works via developed themes like failure diagnosis; educational papers released by using universities characteristically grant insights into modern study tendencies inside this container too!

Conclusion

Implementing Quality Control Measures in Wire Bonding Operations will never be simply an endeavor however an basic ingredient that defines good fortune in electronic manufacturing today. By focusing on comprehensive testing methodologies mixed with effective operational protocols—alongside ongoing schooling projects—establishments can strengthen their production services even though minimizing hazard elements associated with deficient-exceptional connections made due to unreliable ways or applied sciences readily available at hand!

As we preserve progressing in the direction of an increasing number of complicated electronic designs pushing obstacles forward—pleasant guarantee stays paramount! Thus investing time into information these techniques will yield dividends down line—no longer simply financially yet additionally reputation-shrewd among friends within this dynamic industry sector!