CNC Machining: A Revolution in Precision Manufacturing

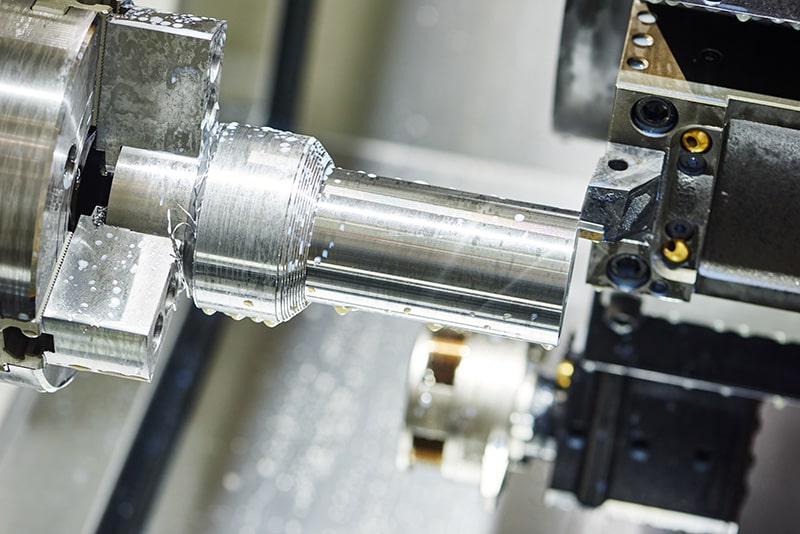

CNC Machining has transformed the manufacturing industry, providing a precise and efficient way to make parts and other components for many industries. This cutting-edge technology utilizes computer-controlled machinery to perform cutting drill, milling and various other processes on kinds of materials like metals plastics, as well as wood. The level of precision obtained via CNC milling is unrivaled, allowing for complex designs to be carried out with extreme accuracy. In replacing manual labor with automation, CNC machines have significantly decreased the chance of human error, and also increased the speed of production. The combination of precision and efficiency has made CNC machines an essential part of modern manufacturing processes.

The primary advantage for CNC machining is the unbeatable accuracy and capability to create high-quality design. As opposed to manual machining in which the operator controls it, CNC machines adhere to specific instructions that cut, shape and form the materials with astonishing precision. It reduces the possibility of error significantly, allowing manufacturing of products which meet exact specifications. Intricate geometries, complex detail, and precise tolerances are possible through CNC manufacturing, making it the ideal tool for businesses that require high standards of precision, like aerospace, in which even slight deviations in parts can have severe implications.

Efficiency is yet another benefit that comes with CNC cutting. After the design has been encoded into the machine it runs automatically making multiple actions with no need for humans to be involved. Automatization results in quicker production and better consistency in the production of parts. Also, CNC machines can operate at a constant rate, which means that producers can make parts round all hours of the day, thus making production more efficient. This is in contrast to traditional machines, which need experienced machinists to control the machinery, CNC machining offers a huge reduction in labor costs and the potential for errors made by human beings, making it a cost-effective solution for high-volume production.

A further benefit of CNC machining is its effectiveness. With the help of automation, machining, manufacturers can significantly reduce the amount of time required to produce parts, leading to faster production cycles and cost savings. Because CNC machines operate 24/7 with minimal human supervision and can produce more output but without degrading the quality. The level of automation lowers the possibility of human error, ensuring that each part produced meets the exact specifications outlined in the digital design. Additionally, CNC machining allows for "lights-out" manufacturing, where machines continue to operate even after employees have gone home to increase productivity, and decreasing labor costs. To find more details kindly check out https://www.premiumparts.com/services/cnc-machining

One of the challenges associated with CNC machining is the cost of initial setup. In the beginning, investing in CNC machines and the software to manage it is costly especially for smaller companies. However, the long-term benefits of CNC machining--such as reduced labour costs, improved efficiency and better manufacturing quality - often exceed the cost of the initial investment. Many companies also provide CNC machining services to businesses which may not have the money to invest in their machinery, allowing small-scale manufacturers to benefit from the technologies without having to pay upfront. While the need for CNC manufacturing continues to grow in the coming years, the cost of machine as well as software is likely to lower, making it easily accessible to more of businesses.

It is predicted that the future for CNC Machining is promising, the advancements in technology are constantly expanding the limits of what machines can accomplish. While CNC machines grow more sophisticated, they're becoming increasingly integrated with other technology, such as 3D printing, robotics and even 3D printing in order to develop hybrid manufacturing techniques which combine the advantages of a variety of techniques. Furthermore, the rise of smart manufacturing as well as manufacturing with the Industrial Internet of Things (IIoT) is enabling greater connection and automatization in CNC machine machining. This allows the machines to interact with each the other and modify their operation according to information from sensors. As the technology continues to develop, CNC machining will remain a vital tool in the advancement of manufacturing technology and will provide even more precision along with speed and adaptability for future generations of products.