The Significance of Training in Manufacturing Processing Techniques

In the contemporary fast-paced manufacturing landscape, the value of training in manufacturing cutting techniques is paramount. As industries increasingly turn to advanced technologies like high-precision laser and water jet cutting services, having a team that is skilled in these methods is necessary. The exactness and productivity offered by these cutting techniques play a pivotal role in enhancing product excellence and reducing production costs, establishing their role within the manufacturing sector.

Training programs focused on commercial cutting prepare employees with the skills necessary to handle cutting-edge equipment safely and effectively. This knowledge not only improves the total productivity of a facility but also encourages a culture of protection and innovation . By investing in comprehensive training, companies ensure that their personnel can fully utilize the potential of laser and water jet cutting technologies, ultimately driving success in a tough market.

Introduction of Cutting Methods

Manufacturing cutting techniques play a vital role in the production process, allowing for accurate and swift material removal. Different methods have emerged to meet the diverse requirements of different sectors, each with distinct pros and abilities. Understanding these techniques is important for companies looking to boost their operations.

Among the widely utilized cutting techniques are lasers and water jet cutting. Laser cutting utilizes a high intensity laser to vaporize materials, offering exceptional precision and clean edges. This method is particularly beneficial for complex designs and can work with a wide range of materials including metal alloys, plastic materials, and glassy materials. Waterjet cutting, on the contrary, employs a high-pressure jet of water, often combined with abrasives, to cut through materials. This technique is favored for its ability to cut thick materials and its environmental benefits, as it produces no thermal effects.

Each cutting technique has its particular applications and is chosen based on parameters like material type, thickness, and required precision. As industries advance, the demand for trained operators and trained professionals in these cutting methods continues to grow. This underscores the necessity of extensive training programs in industrial cutting, ensuring that personnel are furnished with the necessary knowledge and skills to take advantage of these sophisticated techniques effectively.

Benefits of Laser Cutting Technology

This cutting method offers outstanding accuracy that old-fashioned cutting techniques often struggle to achieve. The focused laser beam allows for complex designs and tight tolerances, which is especially important in industries where precision is essential. This precision not only enhances product quality but also reduces material waste, making it a budget-friendly solution for manufacturers aiming to optimize their processes.

A further benefit of laser cutting is its flexibility. This technique can be used on a wide range of materials, including metals, plastic, timber, and textiles. Its flexibility makes it perfect for various applications, from creating intricate prototypes to mass production runs. As a result, companies can take advantage of laser cutting services for varied projects without the need to invest in multiple specialized tools.

Moreover, laser cutting is a cleaner option compared to conventional methods. The process produces minimal debris and requires less post-processing, which contributes to a more productive workflow. laser and waterjet cutting service reduces the time spent on cleanup but also provides a more secure working environment by lowering the risk of injuries associated with conventional cutting techniques.

Advantages of Hydrojet Cutting

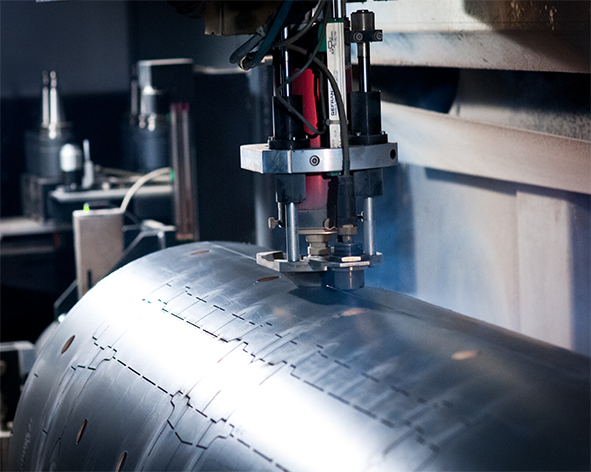

Hydrojet cutting offers remarkable flexibility, allowing for the processing of a wide range of substances including steel, polymer materials, transparent materials, and composite materials. This technique utilizes a high-pressure jet of water mixed with abrasives, allowing it to cut through even the toughest media with exactness. Unlike conventional cutting methods, hydrojet cutting is free of heat, which means it does not alter the characteristics of the material being cut, ensuring the integrity and quality of the finished item.

Another noteworthy advantage of hydrojet cutting is its ability to produce detailed designs and detailed features without the need for additional machining. This precision cutting approach maintains tight tolerances and reduces the risk of mechanical stress or twisting. Furthermore, since hydrojet cutting is a non-contact process, it reduces the chances of material distortion, making it ideal for intricate forms and tight geometries.

Lastly, waterjet cutting is an eco-friendly option compared to other manufacturing cutting methods. It generates minimal waste, as the process typically requires less energy and does not produce harmful emissions or harmful byproducts. This eco-conscious aspect is increasingly important in modern manufacturing, as companies seek to minimize their ecological footprint while achieving high-quality results in their cutting projects.