Digging Deep: Essential Components of an Excavator

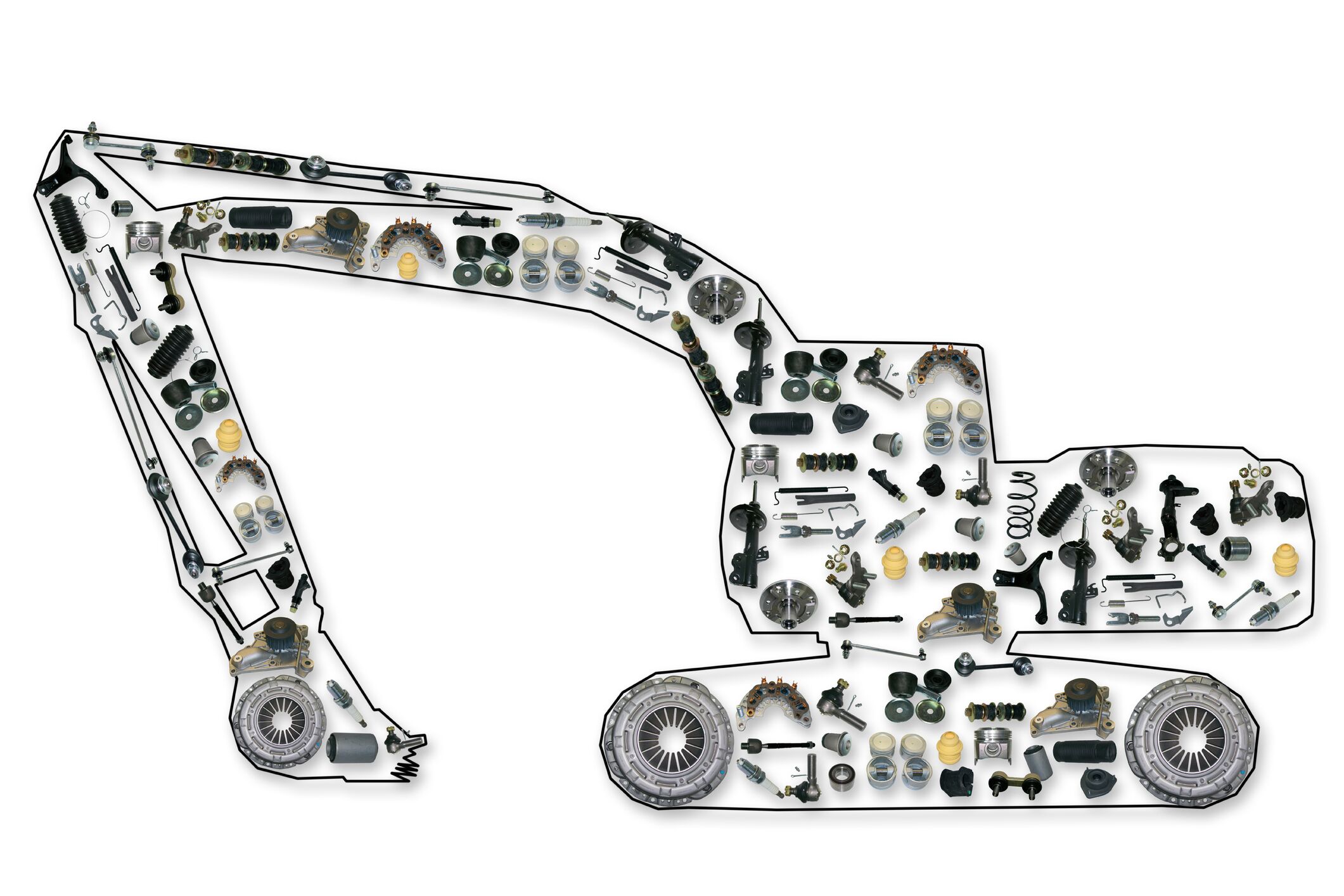

Excavation machines are vital machines in the infrastructure and earthmoving industries, playing a critical role in numerous projects. Whether they're removing foundations, landscaping, or demolition, comprehending the basic components of an excavator can help maximize its efficiency and ensure safe operation. These powerful machines are designed to handle a variety of tasks, and knowing how each part operates is vital for both users and project managers alike.

At the heart of any excavator lies its distinct configuration and the multiple parts that work together seamlessly. From the sturdy tracks that provide transport to the hydraulic systems that enable strong movements, each element contributes to the overall functionality of the excavator. In this article, we will investigate the essential excavator parts, giving you a better insight into what makes these machines so efficient in handling heavy-duty tasks.

Main Boom

This main boom represents a crucial part of an excavator, serving as the principal arm which extends from the upper structure of that machine. The robust structure supports not only the weight of an attachment, such as a bucket or a hammer, but also resists the forces generated during operation. Its length and design of the main boom may vary depending on the type of excavator and its intended use, offering versatility for different digging depths and reach.

Constructed from high-strength steel, the main boom has been engineered to endure significant loads while maintaining structural integrity. Its design allows for hydraulic cylinders to provide the necessary lift and extension, giving operators them to perform a wide range of tasks efficiently. Its boom's articulation may be adjusted, enhancing the excavator's capability to maneuver in confined spaces or tackle challenging terrain.

Moreover, the main boom holds a significant role in the overall stability of the excavator. It helps distribute weight evenly, ensuring that machine remains balanced during operation. A well-designed main boom not only improves performance but also enhances safety by preventing tipping and increasing the efficiency of the digging process.

Arm and Bucket

The arm of an excavating machine is a key component that extends from the body and connects to the bucket. It is designed to provide the necessary reach and maneuverability for excavating and lifting heavy materials. The boom consists of several articulations and hydraulic cylinders that allow it to rotate and retract, enabling the operator to perform diverse tasks with accuracy. The durability and stability of the boom are imperative for the machine to handle the demands of rough and uneven terrain.

The bucket is attached to the end of the boom and is specifically shaped for maximum digging performance. Excavator buckets come in different sizes and designs, each customized for specific applications such as excavating, digging, or material handling. cat parts influences its effectiveness in moving soil, rock, and waste. Factors like width, height, and the type of cutting edge determine how efficiently the scoop can break through the ground and scoop materials.

Together, the arm and bucket form a formidable duo that enables excavators to perform a wide range of tasks. The hydraulic systems that govern them allow for smooth and precise movements, making it simpler for operators to perform intricate operations. Whether used on construction sites, in mining, or for landscaping projects, the synergy between the arm and bucket is crucial for achieving maximum performance and productivity in any excavation work.

Hydraulics Systems

The hydraulic system is is one the most components of an excavator, enabling the vehicle to carry out its tasks effectively and efficiently. This system converts hydraulic fluid into mechanical energy, which drives the various movements of the excavator's arm, bucket, and additional attachments. It is composed of several essential elements, including hydraulic pumps, cylinders, and fluid reservoirs that work together to ensure smooth operation.

Hydraulic pumps siphon fluid from the reservoir and generate pressure that forces fluid into the hydraulic cylinders. Each cylinder is responsible for a specific movement, such as hoisting the boom or inclining the bucket. The accuracy and power of these movements depend on the hydraulic system's configuration and efficiency. High-quality hydraulic components ensure that excavators can support heavy loads and operate at a elevated level of efficiency.

Looking after the hydraulic system is crucial for the durability and reliability of an excavator. Frequent checks of fluid levels, filters, and hoses can stop leaks and mechanical failures, which can lead to costly repairs and downtime. Proper maintenance ensures that the hydraulic system stays responsive and continues to provide the power needed for multiple excavation tasks.