Starting out as Novice into Pro: The Comprehensive Roller Introduction Handbook

In case you've ever found yourself awe-inspired at the sleek and effortless movement of skates flowing smoothly across surfaces, you realize just how important a premium roller entry system is. Regardless of whether you're a beginner eager to boost your skating techniques or an seasoned skater seeking to refine your equipment, grasping the components that play a role to an exceptional roller entry experience remains important. This guide intends to take you from learner to master by exploring the intricacies of roller entry systems, with a focus on durable and corrosion-resistant features that ensure durability and top performance.

As we explore into the field of roller entry guides, you will uncover the diverse materials and designs that distinguish reliable systems from subpar options. Resilient roller entry guides bring superior durability but also boost the overall efficiency of your skates. Meanwhile, corrosion-resistant options are vital for skaters who often moist or humid environments, guaranteeing that your gear endures the test of time. Join us as we guide through what to consider when selecting the ideal roller entry system, enabling you to make wise choices that elevate your skating experience.

Grasping High-Strength Roller Systems

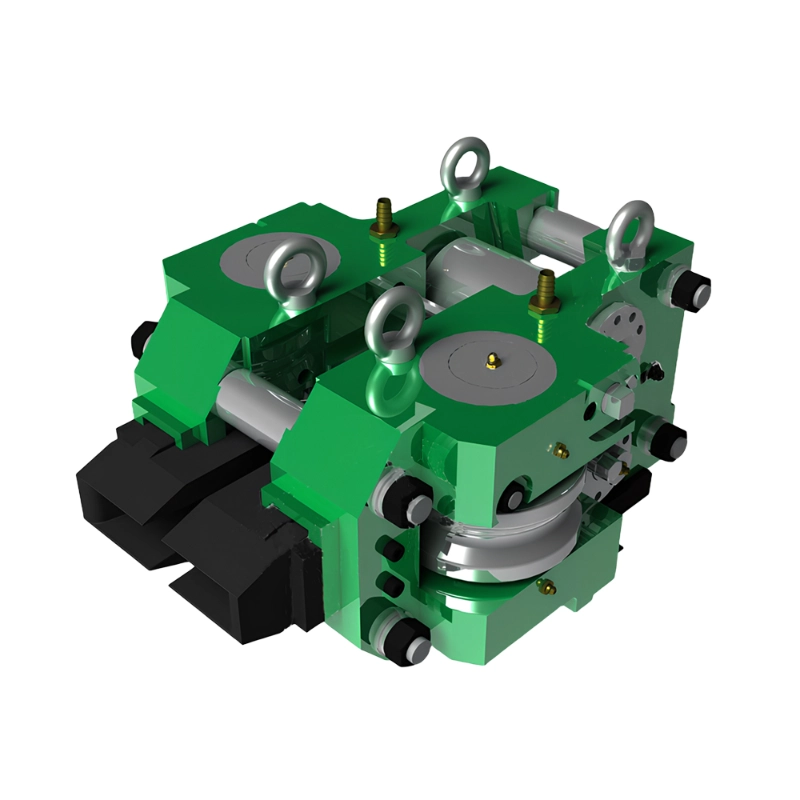

High-strength roller systems are engineered for toughness and optimal functionality in various industrial applications. They are engineered to withstand heavy loads while providing steady operation. These roller entries employ advanced materials and innovative designs to ensure that they can withstand the demands of intensive use. The key to their durability lies in their building, which often includes high-quality steel and enhanced components to boost both performance and longevity.

One of the fundamental benefits of robust roller systems is their capacity to minimize wear and tear on machinery. By providing a secure and solid structure for considerable loads, they help to reduce the friction and pressure that can lead to damage over periods. This not only extends the life of the roller system but also improves the overall efficiency of operations. With a focus on performance, these roller entries significantly improve productivity in various settings.

Another important aspect of robust roller systems is their versatility. They can be tailored for a variety of industries, from fabrication to distribution. Their strong nature allows them to function effectively in harsh environments where traditional rollers might fail. This flexibility makes high-strength roller systems an essential component for businesses looking to enhance their operations and ensure trustworthiness in their equipment.

The Significance of Rust Durability

Rust resistance is a key aspect in the durability and function of roller entry systems. Changes in the environment, such as wetness and interaction to chemicals, can lead to rapid decline of materials. A high-strength roller entry component designed with rust-proof qualities ensures that the devices remains whole and working over time, reducing the likelihood of unexpected failures that could disturb activities.

Spending in oxidation-resistant roller entry guides not only boosts their resilience but also lowers upkeep costs considerably. The need for regular renewals due to damage is lessened, allowing for a more reliable and economical operation. By prolonging the life of the machinery, businesses can apply resources more strategically, focusing on output rather than repairs and renewals.

Furthermore, integrating corrosion resistance into roller entry components showcases a commitment to quality and dependability. This attention lures buyers who seek top-quality items that last. In competitive markets, businesses that focus on long-lasting, oxidation-resistant substances can distinguish and gain a standing as industry leaders, fostering confidence and loyalty among their audience.

Determining the Appropriate Roller Entry for Your Needs

Choosing the right roller entry system is important for achieving smooth-running and effective operation in various applications. Begin by analyzing the individual needs of your project, including the load capacity, speed, and environmental conditions. Strong roller entry guides are ideal for heavy-duty applications where highest durability and support are required. They provide reliability, making them suitable for manufacturing environments that require high performance.

Think about the potential exposure to moisture or destructive substances in your business environment. In such cases, a durable roller entry guide might be the optimal choice. These systems are designed to withstand harsh conditions, ensuring longevity and lowering maintenance needs. This type of guide is particularly beneficial in sectors such as food processing, chemical manufacturing, or coastal applications, where typical materials might break down quickly.

In conclusion, take into account the compatibility of the roller entry with your existing setup. Verify the dimensions and specifications to ensure a proper fit. Some roller entry guides provide adjustable features, which can offer flexibility for different systems. By meticulously evaluating your specifications against the available choices, you can select the most suitable roller entry guide that meets both performance and durability criteria, paving the way to a positive project.