Diesel Generators for Product Validation A Comprehensive Guide

Introduction

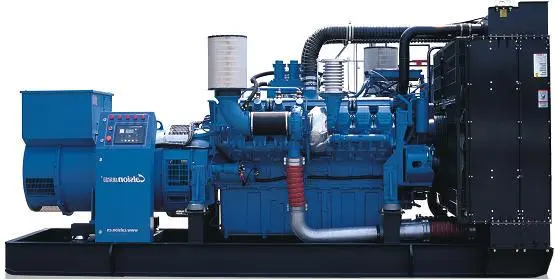

In the world of product validation, ensuring that your products meet the required standards and specifications is crucial for success. One of the key components in this process is the use of diesel generators. 300kw diesel generator for mining operations are widely used in various industries for product validation due to their reliability, efficiency, and cost-effectiveness. In this comprehensive guide, we will explore the importance of diesel generators in product validation and discuss their benefits, applications, and best practices.

Importance of Diesel Generators in Product Validation

Product validation is a critical step in the product development process that involves testing and verifying whether a product meets the required standards and specifications. This process requires a reliable source of power to ensure that the tests are conducted accurately and efficiently. Diesel generators play a vital role in providing the necessary power for product validation activities, such as performance testing, stress testing, and durability testing.

One of the key reasons why diesel generators are preferred for product validation is their reliability. Diesel generators are known for their robust design and ability to provide continuous power for extended periods of time. This reliability is essential for ensuring that product validation tests are completed without any interruptions or failures, which could lead to inaccurate results and costly delays in the product development process.

In addition to reliability, diesel generators are also highly efficient, making them a cost-effective power source for product validation. Diesel generators have a high energy density, which means they can generate a large amount of power using a relatively small amount of fuel. This efficiency not only helps reduce operating costs but also ensures that the power requirements for product validation tests are met without any wastage of resources.

Applications of Diesel Generators in Product Validation

Diesel generators are used in a wide range of product validation activities across various industries. Some of the common applications of diesel generators in product validation include:

1. Performance Testing: Diesel generators are used to provide the necessary power for performance testing of products, such as engines, machinery, and electronic devices. Performance testing involves subjecting the product to different load conditions to evaluate its performance, efficiency, and reliability.

2. Stress Testing: Diesel generators are used to simulate extreme operating conditions during stress testing of products. Stress testing helps identify potential weaknesses or vulnerabilities in the product design and ensures that the product can withstand harsh environments and heavy workloads.

3. Durability Testing: Diesel generators are used to power durability testing equipment that subjects products to repetitive cycles of stress and strain. Durability testing helps assess the longevity and reliability of the product under normal operating conditions.

4. Environmental Testing: Diesel generators are used to provide power for environmental testing chambers that simulate different environmental conditions, such as temperature, humidity, and altitude. Environmental testing helps evaluate the product's performance and reliability in various real-world scenarios.

Best Practices for Using Diesel Generators in Product Validation

To ensure the effective use of diesel generators in product validation, it is essential to follow best practices that help maximize their performance and reliability. Some of the best practices for using diesel generators in product validation include:

1. Regular Maintenance: Regular maintenance of diesel generators is crucial to ensure their optimal performance and reliability. This includes routine inspections, oil changes, filter replacements, and testing of critical components, such as the battery, alternator, and fuel system.

2. Fuel Quality: Using high-quality fuel is essential to prevent fuel contamination and ensure the proper functioning of diesel generators. It is important to store fuel in clean and dry conditions and regularly test it for water content, sediment, and microbial growth.

3. Load Testing: Conducting regular load tests on diesel generators helps verify their capacity and performance under different load conditions. Load testing helps identify any issues or inefficiencies in the generator's operation and allows for timely maintenance and repairs.

4. Emergency Preparedness: Developing an emergency preparedness plan for diesel generators is essential to ensure business continuity in case of power outages or equipment failures. This includes having backup fuel supplies, spare parts, and a contingency power source in place.

5. Noise and Emissions Control: Diesel generators can generate noise and emissions that may impact the surrounding environment and personnel. Implementing noise and emissions control measures, such as soundproof enclosures and exhaust scrubbers, helps minimize the impact of diesel generators on the environment and ensures compliance with regulatory requirements.

Conclusion

Diesel generators play a crucial role in product validation by providing a reliable and efficient source of power for testing and verification activities. Their robust design, high energy density, and cost-effectiveness make them an ideal choice for powering a wide range of product validation tests across different industries. By following best practices for using diesel generators in product validation, businesses can ensure the optimal performance and reliability of their power supply systems, leading to accurate and timely product validation results.