Maximizing Efficiency and Safety with Tinned Copper Power Cables

Introduction

In the realm of electrical engineering and power distribution, selecting the right type of cable is crucial to ensure efficient energy transfer and maintain safety standards. Tinned copper power cables have emerged as a popular choice due to their superior conductivity, corrosion resistance, and durability. This article delves into the intricate details of tinned copper power cables, exploring their composition, benefits, applications, installation guidelines, and maintenance practices.

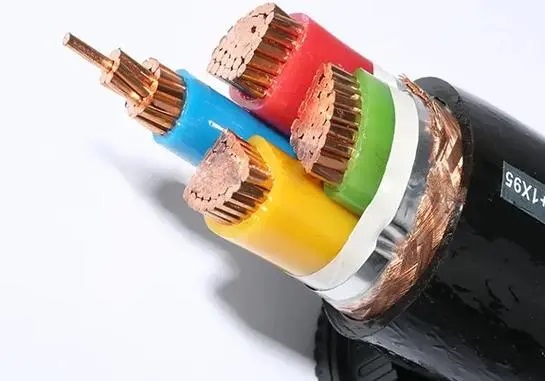

Composition of Tinned Copper Power Cables

Tinned copper power cables are constructed from high-quality copper conductors that are coated with a thin layer of tin. This tinning process involves applying molten tin to the copper surface, creating a protective barrier that shields the underlying material from environmental factors such as moisture, chemicals, and oxidation. The tinning also enhances the conductivity of the cable, allowing for efficient transmission of electrical current.

The insulation material used in tinned copper power cables can vary depending on the specific application requirements. Common insulation materials include PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), and EPR (Ethylene Propylene Rubber). These insulation materials provide electrical insulation, mechanical protection, and resistance to heat and abrasion.

Benefits of Tinned Copper Power Cables

Tinned copper power cables offer a multitude of benefits that make them a preferred choice for various industrial, commercial, and residential applications. Some of the key advantages of tinned copper power cables include:

1. Superior Conductivity: Copper is renowned for its high electrical conductivity, and tinning the copper conductors further enhances this property. Tinned copper power cables ensure efficient energy transfer with minimal power loss, making them ideal for high-current applications.

2. Corrosion Resistance: The tin coating on the copper conductors provides excellent protection against corrosion, extending the lifespan of the cable and ensuring long-term reliability in harsh environments.

3. Flexibility and Durability: Tinned copper power cables are known for their flexibility and durability, allowing for easy installation in tight spaces and resistance to mechanical stress during operation.

4. High Temperature Rating: The insulation materials used in tinned copper power cables are designed to withstand high temperatures, making them suitable for applications where heat resistance is critical.

5. Fire Resistance: Tinned copper power cables are often manufactured with fire-retardant insulation materials, providing an added layer of safety in case of a fire incident.

Applications of Tinned Copper Power Cables

Tinned copper power cables find widespread use in a variety of applications across different industries. Some of the common applications of tinned copper power cables include:

1. Industrial Machinery: Tinned copper power cables are commonly used in industrial machinery and equipment to supply power for motors, control systems, and other electrical components.

2. Renewable Energy Systems: Tinned copper power cables are essential components in solar power systems, wind turbines, and other renewable energy applications due to their high conductivity and durability.

3. Data Centers: Tinned copper power cables are utilized in data centers to provide reliable power distribution for servers, networking equipment, and other critical infrastructure.

4. Marine and Offshore Installations: Tinned copper power cables are well-suited for marine and offshore installations where corrosion resistance and durability are essential in challenging marine environments.

5. Residential and Commercial Buildings: Tinned copper power cables are commonly used in residential and commercial buildings for electrical wiring, lighting systems, and power distribution.

Installation Guidelines for Tinned Copper Power Cables

Proper installation of tinned copper power cables is crucial to ensure optimal performance and safety. Follow these guidelines to ensure a successful installation:

1. Conduct a thorough assessment of the installation environment to identify any potential hazards or constraints that may impact the cable routing and installation process.

2. Select the appropriate cable size and type based on the electrical load requirements, voltage rating, and environmental conditions of the installation site.

3. Ensure that Eco-friendly rubber sheathed cables are properly terminated using approved connectors and terminals to maintain electrical continuity and prevent overheating.

4. Follow the manufacturer's guidelines for bending radius and installation practices to prevent damage to the cable insulation and conductors.

5. Use cable trays, conduit, or raceways to protect the tinned copper power cables from physical damage, chemical exposure, and environmental factors.

Maintenance Practices for Tinned Copper Power Cables

Regular maintenance is essential to ensure the longevity and reliability of tinned copper power cables. Follow these maintenance practices to keep your power cables in optimal condition:

1. Inspect the cable insulation for signs of damage, wear, or degradation. Replace any damaged cables to prevent electrical faults and safety hazards.

2. Check the cable connections and terminations for tightness and proper alignment. Loose connections can lead to overheating and voltage drop issues.

3. Clean the cable surfaces and connectors regularly to remove dust, dirt, and contaminants that can degrade the cable's performance over time.

4. Conduct periodic insulation resistance tests and continuity checks to identify any potential faults or degradation in the cable insulation.

5. Implement a preventive maintenance schedule to monitor the condition of tinned copper power cables and address any issues proactively before they escalate.

Conclusion

Tinned copper power cables offer an array of benefits that make them a reliable and efficient choice for various electrical applications. With their superior conductivity, corrosion resistance, and durability, tinned copper power cables play a critical role in ensuring safe and efficient power distribution in industrial, commercial, and residential settings. By understanding the composition, benefits, applications, installation guidelines, and maintenance practices of tinned copper power cables, electrical engineers and technicians can harness the full potential of these high-quality cables to meet their power distribution needs effectively.