Discovering the Intricacies in Sealed Electromechanical Interfaces

In the world of the vacuum industry, vacuum electrical feedthroughs play an essential role in facilitating the smooth transfer of signals and power into vacuum environments. These high-tech components are designed to keep the integrity of the vacuum while enabling outside electrical connections, which is crucial in numerous applications such as research in science, manufacturing processes, and chip fabrication.

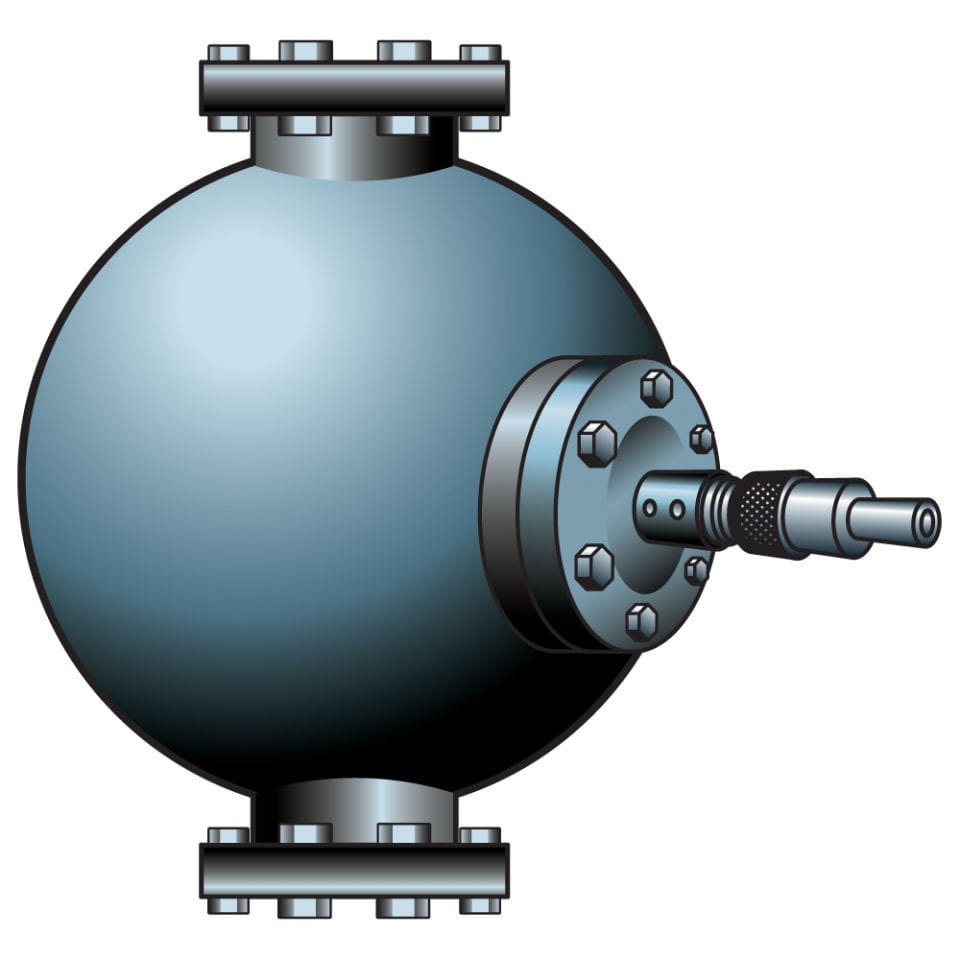

Understanding vacuum feedthroughs involves realizing their construction and operation. They typically consist of conductors that are insulated to prevent electrical leakage and maintain the vacuum seal. Regardless of whether used in experiments in high-energy physics or customized production settings, these feedthroughs ensure that systems operate effectively and efficiently under vacuum environments, safeguarding the delicate balance necessary for optimal performance.

Understanding Vacuum Electrical Feedthroughs

Vacuum-Based electric feedthroughs are custom components that allow electrical signals to pass through a void barrier. They function a critical role in a range of advanced applications, encompassing vacuum setups used in scientific research, manufacturing, and aerospace. By enabling the transmission of electrical power or signals without jeopardizing the integrity of the vacuum, these feedthroughs enable the operation of electrical equipment within austere environments.

Fabricated from materials that can tolerate both the vacuum environment and the electrical requirements, vacuum feedthroughs typically include alloy or ceramic insulators. The design must confirm that any seal is durable enough to stop gas leakage while preserving reliable electrical connectivity. This mix of properties is necessary for applications where precision and cleanliness are paramount, such as in electron-scanning microscopes or particle accelerators.

In addition to, their basic function, vacuum feedthroughs can come in different configurations depending on the particular needs of an application. From multi-pin designs that facilitate multiple signals to travel together to individual pin units for less complex connections, they can be adapted to meet the unique demands of modern technological setups. Their flexibility makes them an key component in ensuring the efficiency and functionality of vacuum systems.

Utilizations of Vacuum Electrical Connectors

Vacuum feedthroughs play a crucial role in multiple areas, particularly in research and development and industrial applications. In laboratories, they are often utilized in pairing with sealed vacuum environments that house experiments requiring controlled environments. These feedthroughs enable the transfer of power and energy to internal components, such as measurement devices and high-precision instruments, without jeopardizing the vacuum conditions. Their dependability and performance are essential for experiments in areas like fundamental physics, material studies, and chip production.

In the electronics sector, vacuum electrical feedthroughs are essential to techniques like layer application and ion insertion. These procedures require a vacuum environment to preserve clean conditions and precise regulation over the properties of materials. The feedthroughs support the provision of current and signal inputs to the machinery used in these processes. This guarantees optimal performance while preventing pollution, which can hinder the quality of the final product.

Another important instance of vacuum electrical feedthroughs is in the field of aerospace and satellite technology. These feedthroughs are employed in a range of instruments and platforms that operate in vacuum conditions, such as satellite sensors and communication devices. They enable the effective conveyance of data and electricity while maintaining the reliability and endurance of devices exposed to demanding vacuum settings. The ability to preserve power connections without compromising the vacuum barriers is essential for the efficacy of space exploration initiatives.

Future Trends in Vacuum Technology

The future of vacuum systems is poised for significant advancements, particularly in the innovation of ultra-efficient and adaptable vacuum feedthroughs . With the growing demand for size reduction and integration in electronic devices, innovations will focus on creating feedthroughs that support electrical signals but also accommodate higher data rates and higher power levels. This will likely involve advanced materials and fabrication processes that can withstand extreme conditions while ensuring efficiency.

Another upcoming trend is the incorporation of smart technologies into vacuum systems. The inclusion of monitoring sensors and IoT functionality within vacuum connections will enable real-time monitoring and diagnostics, boosting operational productivity and stability. This innovative approach will allow users to gather insights into the operation and health of their vacuum systems, facilitating proactive maintenance and minimizing operational pauses.

Sustainability will also play a crucial role in the upcoming of vacuum technology. As industries strive for reduced environmental impact, there will be a move towards more eco-friendly resources and methods in the production of vacuum feedthroughs. This includes the creation of sustainable components and lower energy use during operation, aligning with the international effort for sustainable technologies across diverse fields.