How to Indicate Helical Tieback Anchors in Commercial Concept Records

Helical tieback anchors have a tendency to be the quiet utility vehicles of business base devices. They secure cellar walls versus lateral planet pressure, bandage slice walls in the course of deeper diggings, as well as stabilize beachfront retaining walls where get access to is precarious and also vibration must be restricted. The concept is straightforward, but getting the requirements right is not. A sound spec secures the design intent, provides contractors crystal clear intendeds, as well as leaves behind room for field judgment when dirts carry out not read the memorandum. What observes mirrors the details our experts have a tendency to straighten out on actual projects: the components that fail, the stipulations that spare time and money, and also the submittal products that in fact matter.

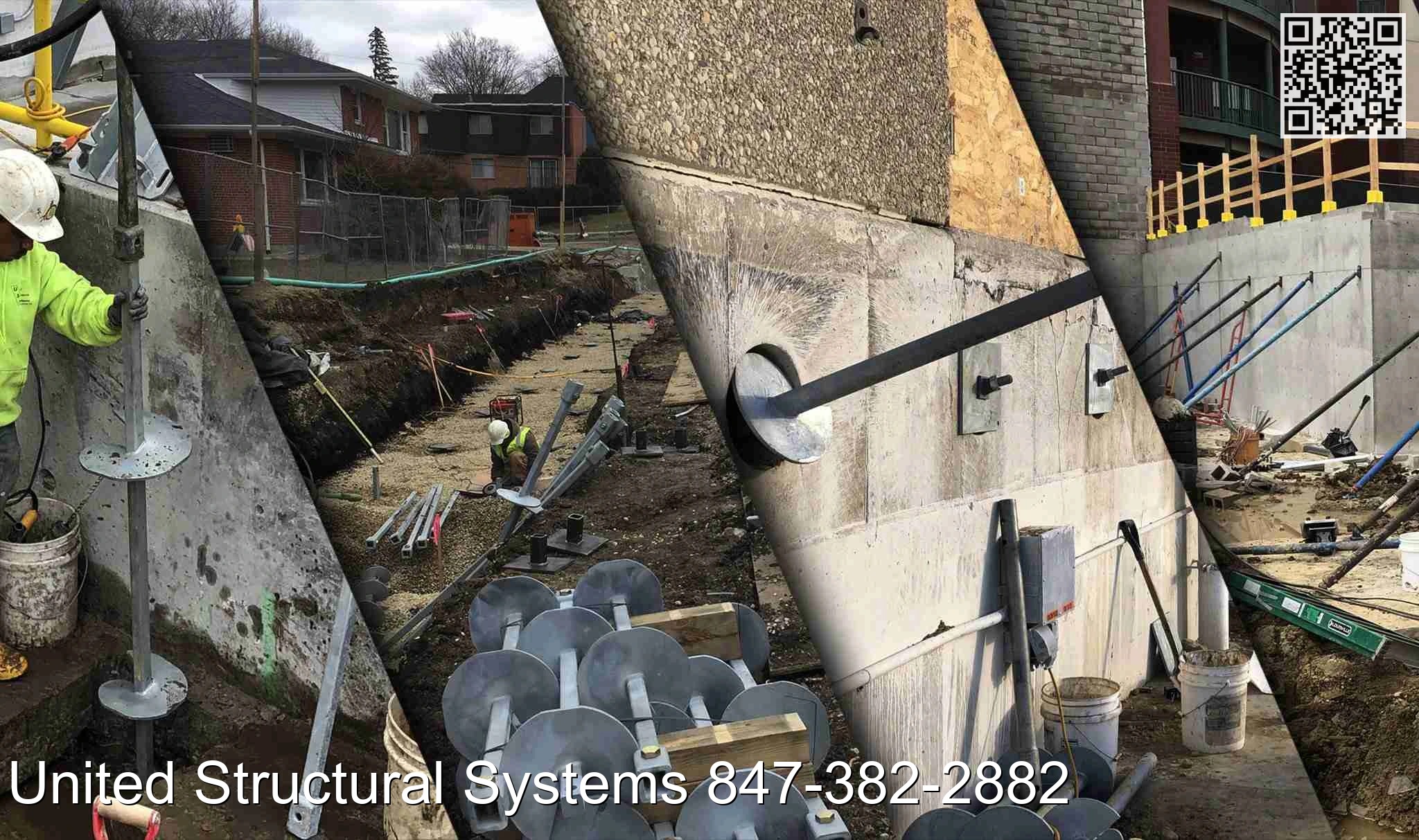

Where tieback anchors suit the commercial toolbox

On office jobs, you will certainly observe helical tiebacks alongside helical piles, resistance piles, and micropiles. Helical piles and resistance stacks lug upright property bunches right into capable strata. Micropiles take care of heavy central needs where expenses is actually limited or even where debris-riddled packs make big arrows not practical. Helical tiebacks, by comparison, stand up to sidewise loads. They are actually commonly made use of jointly along with diaphragm walls, sheet heaps, soldier stack as well as lagging, and also cast-in-place cement cellar walls. It prevails for the exact same specialty specialist to supply both commercial helical pile installation for gravitation bunches and commercial helical tieback anchor installation for side restriction, which simplifies balance as well as testing.

If a task features deep foundation repair or even commercial foundation stabilization, tiebacks may enhance a much older wall structure while helical piles or micropiles take vertical lots coming from brand new framework. On flood-prone or waterfront sites, tiebacks aid keep level splittings up where additional charge as well as hydrostatic disorders differ seasonally. And in city diggings with stringent vibration limits, helical anchors provide functioning ability without the noise and ground disturbance of drilled tieback anchors.

The functionality intent that should lead the spec

A helical tieback anchor is actually a steel shaft with one or more helical platters that is rotated into the dirt to develop axial ability in pressure. The efficiency is actually regulated through:

Helix geometry and also spacing, which controls individual bearing and team interaction. Embedment deepness and inclination, which prepares the length of resisting ground as well as the geometry of the wall structure connection. Soil shear strength as well as system mass, which inform bond ability and creep behavior. Corrosion defense and also resilience regulations, which figure out life span under expected chemistry. Proof and performance testing, which affirm the concept version and also squeeze installment quality.

Start your spec from 1st guidelines: Just how much side tons must the anchor stand up to? What activity can the supported wall accept? For how long must the system final? From certainly there, port in the details. Do certainly not merely paste a supplier sheet.

Coordinate early: geotechnical, structural, and also indicates and also methods

The standard need to demonstrate geotechnical referrals, architectural requirements, and also useful setup constraints. The geotechnical file should deliver undrained shear strengths or even friction slants and also device body weights by intensity, groundwater degrees, constraints on resonance, as well as any kind of corrosivity information. If the document is actually soundless on corrosion, emphasize standard testing for pH, resistivity, chlorides, as well as sulfates at the depths of the helical layers. If the job is actually a fast-track foundation crack repair and opportunity is strict, at least contact the geotechnical designer to resolve presumptions on shear strength and creep.

On the building side, define the wall's style planet stress, surcharge coming from surrounding online bunches or even visitor traffic, and hydrostatic differentials if basement waterproofing changes water drainage. Decide on a tieback disposition and also a connection kind that match the wall structure geometry and rebar design. For soldier heap as well as lagging, the connection is actually usually a waler layer along with a hollow-core or strong pub as well as almond. For cast-in-place walls, a blockout along with a bearing layer and also barrettes simplifies the connection, however examine cover and basement waterproofing particulars. Commercial foundation repair typically includes uncomfortable geometry, thus mockups or even store particulars assist capture conflicts with rebar or ingrained conduits.

Finally, carry out certainly not disregard web site means as well as procedures. Inside tiebacks in existing frameworks demand overhanging space for the travel scalp and sufficient torque reaction. Helical anchors polish where accessibility is actually tight, however even tiny gears need to have functioning area. If the excavation is actually prepared and you need tiebacks as temporary help, the specification must make it possible for reaction frames or even bonded brackets to grasp the wall surface safely and securely during boring. On beachfront retaining walls or crowded power corridors, noise and also resonance limits probably dismiss driven systems like resistance heaps. Helical anchors accommodate these restraints effectively, and also they get married to cleanly with commercial helical pile installation for mixed vertical as well as lateral systems.

Selecting a helical tieback system: shaft, helix, as well as corrosion

Most commercial helical tiebacks utilize either a solid square bar shaft or even a whole vacant bar. Square bar cylinders are actually efficient in strain, transmit torque properly, and also satisfy lumpy fills and also clays along with reasonable obstructions. Round poles are actually stiffer as well as stand up to twisting in grounds along with spaces or mixed loads, but the much larger diameter needs much more twist. For city excavations along with junk or even cinder fill, I often tend to define round bar for the 1st 8 to 12 feets to bridge debris, at that point shift if required. For basement define even clay-based, square bar is frequently adequate as well as economical.

Helix arrangement issues. Normally of thumb, helix layers ought to be spaced at least 3 times the largest helix dimension apart as well as mounted to make sure that a single coil remains in a provided dirt horizon mediocre. what are helical piers Measure helix dimensions cognizant deepness to preserve around consistent worry levels. For instance, a 10-12-14 in stack could be excessive in loosened sand along with groundwater, but a 10-12 in set at a steeper desire might thread right into a denser layer at 25 to 30 feets and deliver reputable ability along with less twist escalation.

Corrosion defense may be propitiatory steel, galvanizing, or even a blend. For a 50-year layout live in mildly corrosive dirt, extra sacrificial fullness on the shaft and also platters typically suffices. Where chlorides or even lost present are credible dangers, point out hot-dip galvanizing to ASTM A123 on plates and also A153 on equipment, and also feature a computed propitiatory reduction based on determined ground resistivity. In threatening web sites, including near industrial outfalls, consider grout encapsulation over crucial sizes or duplex security. Avoid hazy expressions like "adequate deterioration protection." Compose what is needed, just how it will certainly be gauged, and what options the specialist may propose.

Capacity styles as well as installment torque

Helical anchor layout normally links the predicted best capability to the amount of specific helix bearing capacities, adjusted for communication, or even to setup torque making use of a pragmatic torque correlation. Each techniques can be authentic. I favor to explain the style style as well as also require a torque standard as a field inspection. The twist approach relates supreme ability to last setup twist T along with an element KT, commonly in the stable of 8 to 14 for square bar and quite reduced for much larger round cylinders. KT is actually certainly not universal. It relies on ray kind, coil dimension, and supplier testing. Require the professional to specify the KT they mean to make use of, supply test information certain to bum rap as well as coil arrangement, and after that verify it with on-site evidence tests.

Define variables of protection. For permanent supports avoiding sustained payloads, a minimal element of security of 2.0 on greatest ability is common. Where slip control is important, define acceptance based on action under a one-hour grip at 1.33 opportunities the design company tons, using a displacement limit proper to the wall surface system. For short-lived anchors, the element may be lower if justified by testing and monitoring, yet do not skimp on creep sign in soft clays.

Inclination, connect duration, and also wall geometry

Helical tiebacks are generally mounted at angle of inclinations in between 10 and also 30 levels below parallel. Flatter angles lengthen the bond region and minimize vertical bunch elements in the wall surface, however they need even more right-of-way behind the wall. Steeper slants may assist prevent utilities and also property lines but focus coil platters deeper to the wall surface. Goal to place the initial coil at least 6 helix diameters past the energetic wedge or free throw line of possible failure. In slice inclines along with split dirts, press the helix pile to a depth where the most affordable helix dwells in proficient component along with low expected creep. Perform certainly not rely on static resistance near a fresh slice to hold the day.

At the wall structure, information a link that you can easily develop. A bonded or bailed out platter with a ball-shaped washing machine and also almond provides endurance for slight imbalance. In cast-in-place wall surfaces, feature a hollow to accommodate the almond as well as platter thus waterproofing may connect over precisely. If the project includes foundation crack repair, see to it the anchor scalp and also platter do certainly not come down on damaged concrete. If strengthening threads or even heavy blockage appear, a pre-sleeved blockout could protect against blowouts during the course of installation.

Testing that confirms the system works

Field testing is where the specification either saves opportunity or even generates debates. Demand delegations for test operations that observe an identified criterion, like ASTM D3689 for stress bunch exams conformed to helical anchors, and also explicitly specify three examination categories.

Preproduction load exams on propitiatory anchors. These identify the load-displacement feedback in representative soils and also validate the KT relationship in between twist and also capacity. Demand a minimum of two preproduction tests for every specific ground region or support type. Proof examinations on manufacturing anchors, often 5 to 10 per-cent of the total amount. Bunch to 1.5 opportunities the style service load along with grip periods as well as motion standards that record creep. Performance tests when the website geography varies substantially or even when design tons are unusually higher. These exam to greater multiples of company bunch as well as feature organized hold periods to assess time-dependent movement.

Require digital torque records captured at the very least every feet, with downhole disposition readings if offered. The best specialized service providers now match torque information along with GPS depth and driver details that recognize adjustments in gear velocity and also group pressure. When a helical tieback stalls at 18 feets and afterwards documents an action increase in twist at 22 feets, that tells you a sand lens paved the way to heavy till, which adjustment ought to show up in both the torque log and the motion contour during the course of testing.

Allowable motions and sneak criteria

Anchor approval hinges on variation as much as tons. For irreversible tiebacks assisting basement walls, I generally confine activity during verification examinations to just 0.04 inches between the 1- as well as 10-minute readings at 1.33 opportunities solution bunch, with complete movement under the last test tons lower than 0.5 ins. In smooth clays or even very all natural dirts, creep may control capacity. The specification must provide the engineer authorization to call for longer grip periods if the one-minute to ten-minute incline continues to be over target.

If the wall surface system feels, for example glass window curtain wall surfaces settled on a grade-beam tied in to a basement wall, reduced motion restrictions are justified. For brief digging support, specifically for soldier heap and also lagging where activities could be bigger without home consequences, the limits may be a lot more flexible. In either case, put varieties in the specification and also reference the same varieties in the recognition paragraph so there is actually no ambiguity.

Detailing the delegations that matter

A really good helical tieback anchor submittal consists of much more than a lustrous brochure. Seek:

An enclosed style review with the required service and also ultimate tons, disposition, connect length, coil configuration, as well as oxidation defense beliefs, signed through a qualified designer accredited in the job state.

Manufacturer records slabs certain to bum rap and coils, featuring permitted twist, flexible capacity, weld procedures, and also connection hardware capacities.

Installation program determining rig style, get access to paths, torque tracking devices, calibration files, as well as strategies for twist reaction versus the wall or even short-term frames.

Test plannings that cite the typical adhered to, filling schedule, have opportunities, recognition criteria, and data videotaping methods.

Corrosion examination along with dirt chemistry information, selected defense technique, as well as worked out propitiatory allocations or layer thicknesses.

Keep the submittal to-do list tight. The additional centered the demand, the most likely you obtain helpful product as opposed to boilerplate. If the job also consists of commercial resistance pile installation or micropile installation for upright loads, chime with the screening and rust areas throughout bodies to prevent contradictory requirements.

Writing crystal clear acceptance criteria

Build acceptance in to the spec in pair of layers: creation confirmation by twist and also evidence testing outcomes. A traditional set of clauses might explain that each development anchor shall achieve a minimal setup twist correlated to an utmost ability of a minimum of two times the style solution bunch, along with the KT market value originated from preproduction exams. Then, for the anchors picked for verification testing, give displacement limitations at specified grip times and demand a well-maintained rebound contour upon unloading.

Include an acceleration path. If an anchor falls short to connect with torque because of obstruction or weak dirt, enable moving within a described region or permit expansion with extra coil layers, provided minimum spaces and geometry are maintained. If proof testing fails due to excessive creep, require a redesign of the helix setup or even deeper embedment as well as retesting. This prevents disagreements in the business as states evolve.

Dealing with impediments and also variable soils

Commercial websites almost never use book dirts. Junk fills, old foundations, buried energies, and wallets of peat moss may all turn up. Your spec should foresee these realities. Allow for predrilling with superficial blockages where required, yet prepared limitations so predrilling performs not clear away the very grounds the helix overlays necessity to interact. A popular practice is to allow predrilling approximately the top section tip, along with a dimension absolutely no above bum rap diameter, and also to forbid predrilling at coil elevations. For bigger obstructions like abandoned grounds, permit center boring with paperwork of location and also dimension, at that point require the support to extend past the obstacle through a minimum deepness prior to adding up capacity.

In sands below the aquifer, installment twist can easily underpredict size if opening stress dissipate slowly. In extremely gentle clay-baseds, twist can easily overpredict capability because disruption decreases short-term stamina. The option is actually certainly not to leave torque yet to calibrate it along with preproduction exams. Condition this in the spec and insist on site-specific KT.

Connection components and also tons transfer

The support is merely as good as its own scalp. For cast-in-place concrete, a joined plate along with a sleeve and also almond prevails, but look for embedment advantage spans as well as rebar problems. For steel walers on soldier heap wall surfaces, information a platter along with slotted holes to steer alignment adjustments without field flame-cutting. When stainless or even galvanic splitting up is called for because of oxidation problems near beachfront frameworks, define segregating washers as well as appropriate finishes. Where waterproofing is actually vital, coordinate along with the pouch specialist. Penetrations via membranes need to have boots or even hyperlink tapes measured for movement at the load head, as well as those particulars should live in the home collection with crystal clear endorsements to the architectural sheets.

If the venture additionally includes commercial helical pile installation or even micropiles, line up the scalp particulars to ensure that future servicing and examination do certainly not demand specialty resources for one device and also certainly not the other. Congruity conserves time.

Construction resistances as well as documentation

Write tolerances that your inspector can easily measure. For angle of inclination, an endurance of plus or minus 2 degrees is sensible with present day rigs and inclinometers. For place at the wall skin, 1 in is actually attainable, offered the wall structure design is correct. For deepness, point out a minimum depth to the very first coil past the potential failing block, certainly not a max duration. Consist of a criteria that the specialist send as-built logs with the last twist profile page, obtained midsts, disposition sizes, and the identification numbers of the anchors if the maker tracks them.

The best staffs always keep well-maintained, basic logs. On one midtown retrofit that bundled structural foundation repair along with new helical tiebacks, the superintendent taped a laminated chart at the gear: target twist through depth in 5-foot increments based on the preproduction exams. Every driver recognized the objectives for every zone. The as-builts matched the chart within 10 percent, and verification exams were uneventful. That is not luck; it is actually clarity.

Integration with other deep base systems

Tiebacks rarely live alone. Commercial foundation repair typically combinations helical anchors for sidewise tons along with protection piles or even helical piles for settlement deal control. If your job includes commercial resistance pile installation, see to it the tieback format avoids bunch paths that might lower the side bandaging result of piles. As an example, do certainly not position tiebacks thus close to stack teams that their stress bulbs overlap at the same altitude in a way that weakens either system's functionality. With micropiles, watch for casing interference as well as indicate minimal splittings up or setup patterns that stay clear of crowding.

When foundation crack repair on an existing wall becomes part of the scope, determine whether tiebacks are going to momentarily unload the wall surface while epoxy shot or carbon thread support remedies. If therefore, feature tons transactions notes in the sequencing segment and correlative inspection points between building and specialized inspectors.

Sequencing, protection, and also quality control

Helical tieback installation is peaceful as well as easy contrasted to pierced anchors, but it still holds dangers. Reaction structures may impose high powerful lots on somewhat healed concrete. Gear rescinding threats climb on steep excavations. The specification ought to require a site-specific safety and security program that addresses torque reactions, operating systems, and also overhead hazards. In busy buildings, prepared hrs and also resonance thresholds.

Quality management begins along with equipment calibration. Demand twist cell gradation certificates within 6 months and verify regular zero checks on lots cells. Mandate that a qualified manager be present throughout the very first setup of each shift as well as for all verification exams. If weather swings are actually harsh, require a pause when temperatures drop listed below a limit that has an effect on grout or layer relieving, specifically if any sort of grouted encapsulations or bound scalps are actually used.

Writing the spec foreign language with clarity and also flexibility

Crisp language aids. Prevent key phrases like "as needed for a full system." Rather, condition the functionality target and also the appropriate means to show compliance. Maintain exclusive endorsements out unless you possess a basis-of-design product called with an "or identical" clause that really permits equates to. If the task group expects a specific helical support maker as a result of previous performance, be actually straightforward, but safeguard the manager's make use of through allowing backups that fulfill the very same screening background and capacity documentation.

Leave room for field choices that carry out not risk efficiency. Allow the specialized professional to change coil spacing within a pointed out variety to beat obstacles or even twist abnormalities, given minimum required splitting up is sustained and the last arrangement is documented. Enable small changes in incline to prevent energies, yet hat the upright payload element introduced through steeper angles as well as require a change in mind layer ability if needed.

An example synopsis you may adapt

The backbone of an excellent standard has a tendency to follow the same motifs, even though each job is actually one-of-a-kind. When I prepare, I maintain a brief checklist videotaped to my monitor.

Performance criteria: service lots, variables of safety and security, action limitations, and design life with corrosion assumptions. Materials as well as setup: shaft style, coil diameters and spacing, hookup particulars, as well as coatings. Submittals as well as commendations: design calculations, information slabs, setup and also testing programs, and also oxidation evaluation. Installation and also screening: twist monitoring, test categories and approval requirements, tolerances, as well as documentation. Adjustments as well as contingencies: managing obstructions, moving regulations, expansion or redesign induces, and rise roads for fallen short tests.

That overview is actually not a substitute for idea, yet it avoids omission of the items that most often thwart schedules.

Costs, timetable, and also what proprietors care about

Owners love routine of a routine and also shortage of surprises greater than a handful of percent points of component price. Helical anchors are quickly. On a direct cellar wall structure, a two-person workers along with a mid-size gear may put in 8 to 15 anchors daily, depending on intensity as well as access. Checking includes opportunity, and also you should plan for a minimum of one total day for preproduction examinations as well as one to pair of times for evidence testing on a normal 50 to 80 anchor task. Very clear recognition standards steer clear of retesting due to interpretation disputes.

As for cost, straight bar supports with priming and basic scalps are actually usually a lot more efficient every foot than round shaft units, but the dirt governs what works. If you make an effort to spare money by forcing a straight pub with junk, you will definitely pay it back in wasted time as well as harmed leads. If finances pressure is hefty, hope to maximize coil count and also dimensions based upon the examination data instead of squeezing oxidation allotments or even screening regularity. Owners may allow a small superior if it gets self-confidence. They perform not appreciate change purchases when anchors stall except torque.

When not to make use of helical tiebacks

They are certainly not a cure all. If the web site has sizable boulders or cobbles, setup may come to be impractically slow or difficult. In extremely rich antarctic tills with gravel lenses, twist can spike past bum rap as well as coupling limitations prior to the helices hit layout intensity. If significant blockages are actually assumed throughout the whole altitude band, bored soil supports may be actually better suited. In really soft, highly organic soils with a lengthy creep rear, helical anchors can easily obtain twist without trustworthy long-term movement management. Micropiles damaged in stress or even deadman systems might offer much better. The spec needs to empower the geotechnical engineer to contact this pivot based on preproduction results.

Bringing it all together

A well thought-out spec for helical tieback anchors balances quality with flexibility. It establishes quantifiable targets for ability as well as action, describes materials as well as corrosion defense in warrantable terms, and also calls for screening that confirms the system under site states. It expects obstacles and also variation without inviting open-ended improvement orders. And also it includes cleanly along with associated devices like helical piles, protection heaps, as well as micropiles that commonly discuss the very same wall surface pipe. Create what you need, enable what you can, and verify what matters. Do that, as well as your commercial helical tieback anchor installation will definitely support the venture gently and dependably, which is actually precisely what a good anchor needs to do.

UNITED STRUCTURAL SYSTEMS OF ILLINOIS, INC

2124 Stonington Ave Hoffman Estates, IL 60169 847-382-2882 [email protected]> Mon-Fri 8:30am-5:00pm Sat-Sun By Appointment

Ask ChatGPT

Ask ChatGPT Ask Grok

Ask Grok Ask Perplexity

Ask Perplexity Ask Claude

Ask Claude Ask Google AI

Ask Google AI Ask You

Ask You