Vacuumed Windows Exposed: Uses in Contemporary Tech

Within the constantly changing realm of modern technology, sealed viewports serve an important function in allowing a plethora of applications across multiple industries. These specialized lenses, crafted to maintain a sharp line of view while functioning under reduced pressure conditions, are vital in settings where traditional viewports would not suffice. From research labs to industrial operations, vacuum viewports serve as both a partition and a viewing connection, permitting scientists and operators to observe and work with systems that require a vacuum conditions.

The importance of vacuum ports cannot be emphasized enough, as they promote advancements in fields such as substance analysis, semiconductor manufacturing, and even space exploration. By providing unobstructed access to vacuum chambers and other essential environments, these devices enable critical experiments and processes to happen safely and effectively. As we investigate deeper into the uses of vacuum viewports, it is apparent how these seemingly simple parts are at the leading edge of advancement and exploration.

Understanding Vacuum Viewports

Vacuum windows are specific visual interfaces created to enable observational access to a vacuum space while keeping the integrity of that negative pressure. These parts are essential in areas where observation is needed, but the existence of atmosphere can hinder with operations or evaluations. The structure typically incorporates materials that can tolerate significant pressure variations and deliver the required transparency for various ranges of radiation.

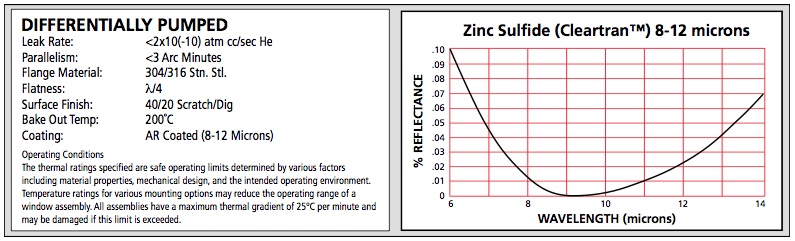

One of the crucial elements of vacuum viewports is their build. They are often made from materials such as silica or specialized transparent materials, chosen for their resilience and capability to allow the passage of radiation without substantial alteration. The gaskets and support structure used to fasten the viewport in place are equally crucial, guaranteeing that no air or contaminants can damage the negative pressure setting. This detailed engineering allows for consistent performance in difficult conditions.

The applications of vacuum windows span across various disciplines, including scientific investigation, semiconductor production, and aerospace engineering. They are essential in setups such as electron imaging systems, where high negative pressure is required for ideal visualization of specimens. Additionally, in the semiconductor sector, vacuum windows are used in sterile environments, aiding processes like photoetching and carving, where any pollution could lead to issues in semiconductive devices.

Key Applications in Technology

Vacuum viewports are crucial components in various advanced environments. One primary application is in scientific studies, particularly in areas such as high-energy physics and solid-state physics. These viewports allow scientists to observe events under regulated vacuum conditions, enabling experiments that necessitate a significant level of precision and isolation from air interference. For example, in particle accelerators, vacuum viewports offer researchers unmediated visual access to experimental setups, which enables instantaneous observation of collisions.

Another notable application is in the aerospace industry, where vacuum viewports are used in testing facilities that mimic the rigorous scenarios of space. These chambers help engineers evaluate satellite components and other space equipment under vacuum conditions. The ability to physically monitor test procedures through vacuum viewports allows for that any potential issues can be identified and addressed promptly, enhancing the dependability of aerospace technologies before they are deployed into orbit.

Additionally, vacuum viewports hold a critical role in the semiconductor manufacturing process. In this industry, preserving a vacuum is crucial to reduce contamination and defects during the production of microelectronic devices. Vacuum viewports allow engineers to examine and monitor procedures such as layer application and etching within vacuum chambers without compromising the environment. This functionality is essential for maintaining the elevated outputs and quality benchmarks required in semiconductor production.

Future Trends and Innovations

As tech keeps to progress, the evolution of vacuum viewports is projected to evolve in tandem with new fields such as advanced optics and material engineering. Researchers are examining new materials that provide improved durability and better thermal resilience, allowing vacuum viewports to operate efficiently in a range of challenging environments. Innovations in coating technologies are also in progress, which may lead to better anti-reflective properties and enhanced performance in harsh conditions.

In the area of space exploration, vacuum viewports will play a pivotal role in enabling more complex scientific instruments. Future missions to Mars and beyond are likely to utilize cutting-edge vacuum viewports to protect sensitive equipment from both severe atmospheric conditions and likely contamination. These advancements will facilitate more accurate data collection and improve our understanding of alien environments, advancing the boundaries of what we can realize in space science.

Moreover, the combination of vacuum viewports with smart technology is on the horizon. The possibility for immediate monitoring and adaptive responses in various commercial applications could revolutionize how vacuum systems are managed. Smart sensors integrated into vacuum viewports may allow for self-regulating systems that optimize performance based on environmental changes, thereby increasing performance and dependability in fields ranging from manufacturing to aerospace.