The Silent Sentinel How Hysteresis Brakes Are Revolutionizing Control One Frictionless Stop at a Time ⚙️🔒

Imagine the heart-stopping plunge of a roller coaster 🎢, not the terrifying freefall, but the exhilarating, controlled descent. The precise, smooth deceleration that builds excitement without jarring your spine. Or picture the life-saving precision of an MRI machine 🏥, its powerful magnets rotating silently, requiring absolute stability without a hint of vibration to blur the critical image. Perhaps consider the automated packaging line in a factory 🏭, whirring away at high speed, needing to place delicate products with pinpoint accuracy, over and over, hour after hour. What unseen force masters these moments of critical control? Often, it's the unsung hero working tirelessly behind the scenes: the hysteresis brake.

This isn't your grandfather's friction brake, screeching and sparking, wearing down with every application. The hysteresis brake operates on an entirely different principle, a beautiful interplay of physics that delivers unparalleled smoothness, consistency, and longevity. It’s the maestro of controlled torque, the guardian of precision in a world demanding ever-higher levels of performance and reliability. Forget brute force; embrace intelligent control. This is the era of hysteresis.

**The Invisible Hand: Unpacking the Magic ✨**

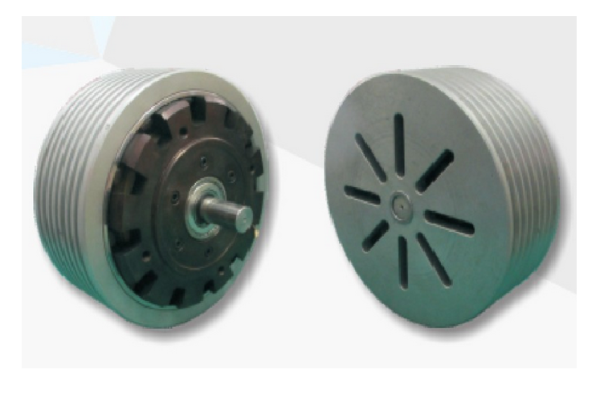

So, how does this technological marvel work without grinding metal on metal? The secret lies in magnetism and the inherent properties of certain materials. At its core, a hysteresis brake consists of two key components: a rotor (often a disc) made from a special magnetic material and a stationary stator housing containing electromagnetic coils. Here's the elegant sequence:

1. **The Magnetic Call:** When an electrical current flows through the stator coils, a magnetic field is generated. This field penetrates the rotor disc.

2. **Material Memory (Hysteresis Loss):** This is where the magic happens. The rotor material isn't perfectly receptive; it has a kind of \"magnetic memory\" or reluctance to change its magnetization instantly. As the rotor tries to spin within this changing magnetic field, the magnetic domains within the material resist realignment.

3. **The Frictionless Fight:** This internal resistance to the changing magnetic field – this hysteresis loss – manifests as a braking torque. The energy expended in constantly remagnetizing the material as it moves is converted directly into heat. Crucially, there is no physical contact or mechanical friction between the rotor and the stator.

4. **Smooth Control:** The magnitude of the braking torque is directly proportional to the strength of the magnetic field, which is controlled precisely by the input current. Increase the current, increase the braking force. Decrease it, and the braking eases. It’s linear, predictable, and incredibly smooth.

**Why Hysteresis? Ditching the Old Guard 🆚**

In a landscape saturated with braking solutions, why is hysteresis technology storming ahead? The advantages are profound and address critical pain points engineers face daily:

* **Silent, Smooth Operation 🤫:** The absence of physical contact means no squealing, grinding, or chattering. Just pure, silent torque control. This is non-negotiable in noise-sensitive environments like laboratories, medical settings, recording studios 🎧, and high-end consumer electronics.

* **Unmatched Consistency \u0026 Repeatability ♻️:** Friction brakes wear. As pads or linings degrade, torque output changes. Hysteresis brakes? Their torque is purely a function of the input current and the magnetic properties of the rotor – both inherently stable over time. This means the braking force you set today is the braking force you get tomorrow, next month, or next year, cycle after countless cycle. Critical for robotics, automated testing equipment, and winding applications where tension must be perfect every single time.

* **Longevity Champion 🏆:** No friction means dramatically reduced wear and tear. The rotor can spin virtually indefinitely without degradation. Bearings might eventually need replacement, but the core braking mechanism itself has an exceptionally long operational life, minimizing downtime and maintenance costs significantly.

* **Precision Control at Your Fingertips 🎮:** Controlling torque with an electrical signal is incredibly precise and responsive. Need fine adjustments? Dial the current up or down minutely. Need constant tension regardless of speed? Hysteresis brakes deliver consistent torque from near-zero RPM up to high rotational speeds. Friction brakes often struggle with low-speed control and \"stick-slip\" phenomena.

* **Cleanliness is Key 🧼:** No friction means no dust, no debris, no oil mist. This inherent cleanliness is vital for semiconductor manufacturing, food and pharmaceutical processing, clean rooms, and any application where contamination is a critical concern.

* **Overload Tolerance 💪:** Need to hold a load statically? Hysteresis brakes excel at maintaining torque without overheating, even when stalled indefinitely (within their thermal design limits). Friction brakes relying on clamping force can overheat and fail under prolonged static load.

* **Minimal Inertia Impact:** Rotor designs can be optimized to have very low rotational inertia, meaning they accelerate and decelerate the load efficiently without adding significant dynamic burden to the system. This is crucial for high-speed, responsive applications.

* **Zero Backlash:** Immediate response to control signals without any mechanical slack or delay. Essential for precision positioning systems.

**Where the Magic Happens: Hysteresis Brakes in Action 🌍**

The unique benefits of hysteresis technology make it the preferred choice across a surprisingly diverse spectrum of industries. Let’s explore some real-world champions:

1. **Aerospace \u0026 Defense ✈️🔧:** Simulators requiring incredibly smooth motion cues, antenna positioning systems demanding precise, vibration-free movement, gyroscope testing equipment needing absolute stability. Hysteresis brakes provide the silent, reliable control these high-stakes applications demand.

2. **Medical \u0026 Life Sciences 🧬🩺:** MRI and CT scanners rely on hysteresis brakes for smooth rotation and precise stopping of heavy gantries without disturbing sensitive imaging. Robotic surgical arms utilize them for tremor-free movement and delicate force feedback. Centrifuges, automated laboratory analyzers, and patient positioning systems all benefit from their cleanliness, silence, and precision.

3. **Industrial Automation \u0026 Robotics 🤖🏭:** This is a powerhouse application. Hysteresis brakes are the go-to solution for:

* **Web Handling \u0026 Converting:** Maintaining perfect tension on paper, film, foil, textiles, and wires during unwinding, processing, and rewinding. Essential for preventing wrinkles, breaks, and ensuring consistent product quality. Think printing presses, plastic film extruders, wire winding machines.

* **Robotics:** Providing controlled resistance for joint movement, enabling smooth force feedback, safe collaborative operation (cobots), and precision in assembly tasks.

* **Packaging Machinery:** Controlling the feed of materials, ensuring accurate placement of products, and providing gentle stopping for delicate items.

* **Test \u0026 Measurement Equipment:** Applying precise, repeatable loads for material testing, fatigue testing, and component qualification. Torque testers use hysteresis principles extensively.

4. **Entertainment \u0026 Simulation 🎮🎥:** Flight simulators, driving simulators, and motion platforms for theme park rides depend on hysteresis brakes to deliver incredibly smooth, realistic forces and movements without the noise and vibration of friction solutions. Camera dollies and cranes use them for silky-smooth panning and tilting.

5. **Consumer \u0026 Office Electronics 🖨️💻:** High-end printers use hysteresis brakes for precise paper feed control. Automatic document feeders, scanners, and even some high-fidelity turntables utilize their silent, consistent torque.

6. **Energy \u0026 Power Generation 🌬️🔋:** Controlling the yaw and pitch of wind turbine blades requires reliable, maintenance-friendly brakes. Hysteresis technology is increasingly finding a role here, and in dynamometer testing for engines and motors.

7. **Material Handling \u0026 Logistics 📦🚚:** Automated guided vehicles (AGVs), conveyor systems requiring controlled deceleration, and lifting mechanisms benefit from the smooth, reliable stopping power.

**Beyond the Basics: Choosing and Optimizing Your Hysteresis Solution 🔍**

Selecting the right hysteresis brake isn't just about picking the biggest torque rating. It's a nuanced process:

* **Torque Requirements:** Peak torque? Continuous torque? How does torque need to vary with speed? Understanding the full duty cycle is crucial.

* **Speed Range:** What are the minimum and maximum operating speeds? Some designs perform better at very low speeds than others.

* **Heat Dissipation 🔥:** Torque generation creates heat. Can the brake naturally dissipate it? Or is forced air cooling needed? Ambient temperature matters. Thermal management is key to longevity.

* ** servo press Matching:** The inertia of the brake's rotor adds to the system's total inertia. Minimizing this is often desirable for dynamic response.

* **Mounting \u0026 Integration:** Size constraints, shaft sizes, mounting orientation (horizontal/vertical), and environmental factors (IP rating, exposure to chemicals) all play a role.

* **Control Interface:** Simple analog voltage/current control? Or digital communication (CANopen, EtherCAT) for integration into complex control networks?

* **Feedback Options:** Is speed or position feedback (tachometers, encoders) required? Many hysteresis brakes can be integrated with sensors.

**Maximizing Performance and Lifespan:** Once selected, ensure optimal performance:

* **Proper Sizing:** Avoid under-sizing (overheating) and over-sizing (cost, inertia penalty). Leverage manufacturer sizing tools and expertise.

* **Adequate Cooling:** Respect thermal limits. Ensure good airflow around the brake if relying on convection. Use forced air if necessary, especially for high-duty cycles or high ambient temperatures.

* **Clean Power Supply:** Stable, ripple-free DC power ensures consistent torque control and protects the coils.

* **Protect from Overload:** While robust, exceeding thermal limits repeatedly will degrade performance. Implement system-level safeguards.

* **Lubrication (Bearings):** Follow manufacturer guidelines for bearing lubrication intervals if applicable.

**The Future is Frictionless: Innovations and Trends 🔮**

Hysteresis brake technology isn't standing still. Continuous innovation pushes the boundaries:

* **Enhanced Thermal Management:** New materials and cooling fin designs are improving heat dissipation, allowing higher continuous torque in smaller packages.

* **Integrated Intelligence 🧠:** Brakes with embedded controllers, communication protocols, and self-diagnostic capabilities are emerging, simplifying integration and enabling predictive maintenance.

* **Advanced Materials:** Research into magnetic materials aims to achieve higher torque density (more torque per unit size/weight) and potentially wider operating temperature ranges.

* **Compact \u0026 Lightweight Designs:** Driven by robotics, aerospace, and portable equipment, the push for miniaturization continues without compromising performance.

* **Energy Efficiency Focus:** While inherently efficient in operation (no wasted friction heat *beyond* the hysteresis losses), designs are evolving to minimize heat generation itself where possible.

* **Broader Adoption in New Markets:** As awareness grows and costs become more competitive, hysteresis technology is finding its way into applications previously dominated by friction brakes or clutches, driven by the demand for reliability, quietness, and precision.

**Embracing the Silent Revolution: Your Competitive Edge Awaits 🚀**

In a world where precision, reliability, quietness, and cleanliness are paramount competitive advantages, settling for outdated, friction-based control mechanisms is no longer viable. Noise pollution regulations tighten. Quality standards soar. Maintenance budgets shrink. The demand for seamless human-machine interaction intensifies.

Hysteresis brake technology offers a fundamental shift. It’s not just a component; it’s an enabler. It enables:

* **Superior Product Performance:** Smoother operation, finer control, higher consistency – translate directly to better end-user experiences and superior product quality.

* **Reduced Operational Costs:** Slash maintenance downtime and parts replacement costs. Extend equipment lifespan dramatically.

* **Enhanced Brand Reputation:** Deliver the quiet, reliable, high-precision performance that builds trust and differentiates your products in the marketplace.

* **Meeting Stringent Regulations:** Easily comply with noise and contamination standards across industries.

* **Unlocking New Design Possibilities:** Enable applications where friction brakes simply cannot perform adequately, opening doors to innovation.

**Taking the Next Step: From Insight to Implementation**

The potential is clear. The technology is proven. The question shifts from \"Why hysteresis?\" to \"How do we integrate this into *our* next breakthrough?\"

This isn't about replacing every brake overnight. It's about identifying those critical points in your machinery, your processes, your products, where the limitations of friction are holding you back. Where vibration compromises quality. Where noise detracts from the experience. Where maintenance interrupts production. Where inconsistent control leads to waste.

Start the conversation. Engage with engineers who specialize in this technology. Discuss your specific challenges – the need for constant tension on a delicate web, the requirement for a silent brake in a medical device, the demand for precise, repeatable torque in robotic assembly. Explore the possibilities.

Imagine your next product launch, heralded not just for its features, but for its whisper-quiet operation and buttery-smooth control. Envision your production line humming with unprecedented efficiency, free from the downtime of friction brake maintenance. Picture the complex motion achieved with effortless precision.

The silent sentinel, the hysteresis brake, is ready to guard your performance, elevate your quality, and propel your innovation. It’s time to harness the power of frictionless control and step confidently into a smoother, quieter, more reliable future. The revolution is already spinning, silently and powerfully. Are you ready to join it? 🤝💡