Unlocking Innovation: Exploring the Versatile Applications of Plastic Injection Molding Services

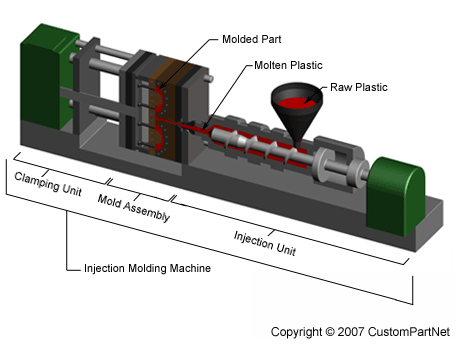

In today's fast-paced and ever-evolving manufacturing landscape, the quest for innovation is a driving force that propels industries forward. Among the many techniques that have emerged to foster creativity and efficiency, plastic injection molding services stand out as a cornerstone of modern production methods. This versatile process not only streamlines the manufacturing of complex parts but also opens up a world of possibilities for businesses seeking to enhance their product offerings.

From automotive components and consumer goods to medical devices and packaging solutions, the applications of plastic injection mold services are vast and varied. This method allows for the creation of intricate designs with high precision and repeatability, making it an essential choice for industries that demand quality and performance. As we delve deeper into this topic, we will explore how plastic injection molding can unlock innovation across different sectors, driving progress and meeting the ever-growing demands of consumers.

Key Benefits of Plastic Injection Molding

Plastic injection molding is a highly efficient manufacturing process that offers significant advantages for various industries. One of the primary benefits is its ability to produce complex shapes with high precision. This precision allows for detailed designs that can meet specific functional requirements while maintaining consistency across large production runs. As a result, businesses can achieve a level of quality that is often difficult to replicate with other manufacturing methods.

Another key benefit is the speed of production. Once the molds are created, the injection molding process can produce thousands of parts in a short time. This efficiency reduces the overall time to market, allowing companies to respond quickly to changing demands and customer needs. The scalability of the process means that manufacturers can easily adjust production volumes without sacrificing quality or increasing costs dramatically.

Cost-effectiveness is also a major advantage of plastic injection molding. Although the initial investment in mold creation can be high, the long-term savings often outweigh these costs. The reduced waste and materials required for production, combined with lower labor costs due to automation, make it an economically viable option for producing a wide range of plastic components. Overall, plastic injection mold service proves to be a smart choice for businesses looking to innovate while keeping budgets in check.

Industries Leveraging Injection Molding

Plastic injection molding is a critical process utilized across various industries for its efficiency and adaptability. In the automotive sector, manufacturers leverage injection molding to produce lightweight yet durable components. Parts such as dashboards, bumpers, and interior fittings benefit from the precision and customization that injection molding offers, contributing to both performance and aesthetics while reducing overall vehicle weight.

The consumer electronics industry also represents a significant application area for plastic injection molding. From smartphone casings to intricate circuit board housings, this process allows for the mass production of complex shapes and designs. As technology evolves, the need for lightweight, portable, and robust electronic devices drives the demand for high-quality molded components that can withstand daily use while maintaining an attractive appearance.

In the medical field, plastic injection molding plays an essential role in creating components that meet strict regulatory standards. Medical devices such as syringe bodies, respiratory masks, and surgical instruments require precision and reliability. Injection molding provides the necessary manufacturing capabilities to produce these devices efficiently while ensuring compliance with safety standards, thereby contributing to advancements in healthcare technology.

Future Trends in Plastic Injection Molding

As industries continue to evolve, plastic injection molding services are adapting to meet the demands of modern manufacturing. One significant trend is the increasing focus on sustainability. Manufacturers are exploring biodegradable plastics and recycled materials to reduce their environmental impact. This shift not only aligns with global sustainability goals but also attracts environmentally conscious consumers. The production of eco-friendly components will likely become a competitive advantage as more companies seek ways to minimize their carbon footprint.

Another important trend is the integration of advanced technologies such as automation and artificial intelligence. These technologies enhance precision, efficiency, and flexibility in the injection molding process. Automated systems can streamline production lines, leading to faster turnaround times and reduced labor costs. Furthermore, AI-driven analytics can optimize design processes, enabling manufacturers to anticipate market needs and improve product development timelines. This technological advancement positions plastic injection molding as a future-ready solution for diverse industries.

Lastly, the rise of customization in consumer products is influencing the landscape of plastic injection molding services. Businesses are increasingly demanding tailored solutions that meet specific customer preferences. As a result, mold design and production capabilities are becoming more versatile, allowing for greater creativity in product design. This trend not only caters to individual customer needs but also fosters innovation, pushing manufacturers to explore new possibilities in material usage and design complexity. Embracing customization will undoubtedly shape the future of plastic injection molding services in a dynamic market.