What are the typical concerns and difficulties in PCB assembly and exactly how to address them

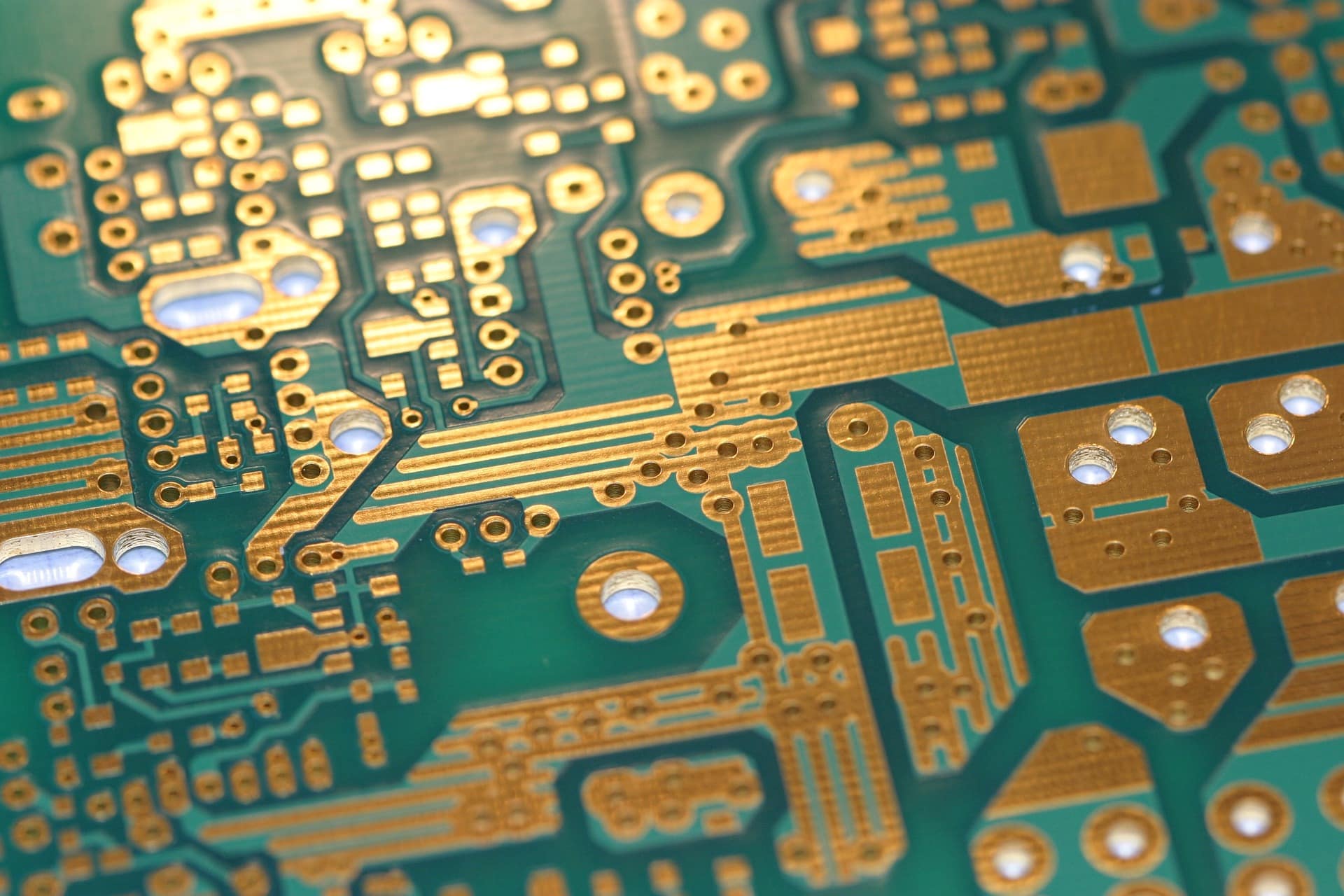

Printed Circuit Board (PCB) assembly is an intricate process that entails different stages, from element positioning to soldering and testing. Regardless of web link , PCB assembly still encounters many challenges that can impact the efficiency, dependability, and cost-effectiveness of the end product. This post explores common issues in PCB assembly and offers services to mitigate them.

1. Expense of Materials (BOM) Issues

A regular concern in PCB assembly is mistakes or variances in the Expense of Products. An inaccurate or insufficient BOM can result in hold-ups and enhanced costs because of the procurement of incorrect components.

Option: To combat BOM problems, it is necessary to have an extensive evaluation process. Utilizing software application devices for BOM monitoring can assist in validating part numbers, descriptions, and guaranteeing all components are appropriately noted and sourced.

2. Wrong PCB Footprints

Dissimilar component impacts can result in assembly issues where parts do not fit the marked rooms on the PCB.

Service: This can be prevented by ascertaining the footprint data against the real components throughout the design stage. Collaboration between the style team and component distributors is important to ensure accuracy.

3. Design for Manufacturability (DFM) Errors

DFM errors happen when PCB designs are not enhanced for production, resulting in problems in assembly and raised manufacturing costs.

Solution: Executing DFM checks during the design process aids recognize prospective manufacturing problems early. Making use of DFM guidelines and functioning closely with the PCB manufacturer can considerably reduce these mistakes.

4. Soldering Flaws

Soldering defects, such as cool joints, solder bridges, or insufficient solder, prevail in PCB assembly. These defects can result in bad electric links and lowered dependability.

Service: Correct training for hand-operated soldering professionals and regular upkeep and calibration of automated soldering equipment are important. Additionally, executing rigid quality control checks can help determine and fix soldering problems without delay.

5. Thermal Problems

PCBs can struggle with thermal issues due to incorrect warmth distribution, leading to part damages or failure.

Solution: Designing PCBs with thermal administration in mind is essential. This consists of making use of thermal alleviations, correct element spacing, and selecting materials with ideal thermal properties.

6. Component Positioning Errors

Inaccurate positioning of components can create practical failings or make the assembly procedure difficult.

Service: Automated placement devices must be frequently adjusted. Additionally, employing optical assessment systems can discover and correct positioning errors before soldering.

7. Supply Chain Issues

Delays or shortages in element supply can stop the PCB assembly procedure, influencing the time to market and overall prices.

Solution: Building solid relationships with several suppliers and keeping a supply of vital parts can alleviate supply chain risks. Forecasting and planning for lengthy lead-time components are also crucial.

8. Ecological Stress and Physical Damage

PCBs can be harmed because of environmental stresses or mishandling during the assembly procedure.

Option: Carrying out robust handling and storage treatments is crucial. Making use of safety packaging and regulating ecological variables like humidity and temperature level in the assembly location can lower the risk of damage.

9. Quality Assurance Difficulties

Making sure constant quality in PCB assembly is a considerable challenge, particularly for complex boards.

Remedy: Establishing a comprehensive quality control system, consisting of automated optical examination (AOI), X-ray examination, and functional testing, can help preserve top notch requirements.

10. Expense Management

Balancing the cost of PCB assembly with high quality and performance requirements is a constant challenge.

Option: Expense monitoring can be attained by maximizing the style for cost-effectiveness, working out with vendors, and constantly boosting the assembly procedure for effectiveness.

To conclude, while PCB assembly faces numerous obstacles, a combination of cautious layout, detailed planning, quality assurance, and effective interaction with distributors and manufacturers can resolve these issues. By taking on these remedies, PCB assembly can be enhanced for dependability, performance, and cost-effectiveness, guaranteeing the effective manufacturing of top notch electronic gadgets.