From Waste Materials to Value: Automated Manufacturing Plants Redefining Sustainability

In a period in which sustainability is now an essential part of consumer expectations , businesses face growing challenges to rethink methods to product design and manufacturing. Intelligent factories are at the forefront of this change , incorporating state-of-the-art technologies to innovate processes that minimize waste and enhance resource efficiency. By harnessing data analytics , automation, and the connected devices, these modern manufacturing facilities are transforming what it means to create products that not only meet market demands but also align with eco-friendly values .

The notion of merging sustainability into designing products is no longer just a distant dream but a current truth made possible by intelligent manufacturing systems . These facilities prioritize sustainable materials , principles of circular economy, and sustainable production methods. As a result, organizations that embrace these practices are not only contributing to a healthier planet but are also discovering fresh opportunities for increased profits and customer loyalty . This article explores how advanced manufacturing facilities are at the forefront in developing a sustainable future , transforming waste into assets through innovative design and manufacturing processes .

Cutting-edge Product Development

In the realm of smart factories, creative product design is crucial for combining sustainability with production methods. Designers are progressively concentrating on developing products that not only fulfill consumer demands but also lessen green impact. This approach evaluates the entire lifecycle of a product, from obtaining materials to end-of-life. By using sustainable materials and cutting waste through careful design, manufacturers can significantly decrease their carbon footprint while still providing high-quality products.

Moreover, smart technologies play an key role in supporting this innovative design process. Advanced software and simulation tools allow designers to see and analyze various material uses and production methods before starting manufacturing. This functionality enables teams to pinpoint potential problems or environmental concerns at the design stage, allowing for rapid adjustments. The use of 3D printing and other additive manufacturing techniques also opens up possibilities for producing complex structures that maximize material use and reduce excess waste.

Ultimately, collaboration between various stakeholders, including engineers, designers, and environmental scientists, is essential for promoting this progressive product design ethos. By collaborating, teams can create products that incorporate the principles of sustainability, ensuring that they are built to last and can be quickly disassembled or repurposed. This joint effort, combined with advanced technology, positions smart factories at the forefront of sustainable manufacturing, ultimately redefining how products are manufactured and produced.

Advanced Manufacturing Techniques

Smart production processes utilize advanced technologies to enhance the efficiency and sustainability of production. By integrating Internet of Things devices, artificial intelligence, and large-scale data analytics, producers can collect immediate information from their processes. This data enables businesses to monitor resource consumption, reduce waste, and improve overall operational productivity. As a result, organizations can make informed decisions that not only enhance production but also promote environmentally friendly practices.

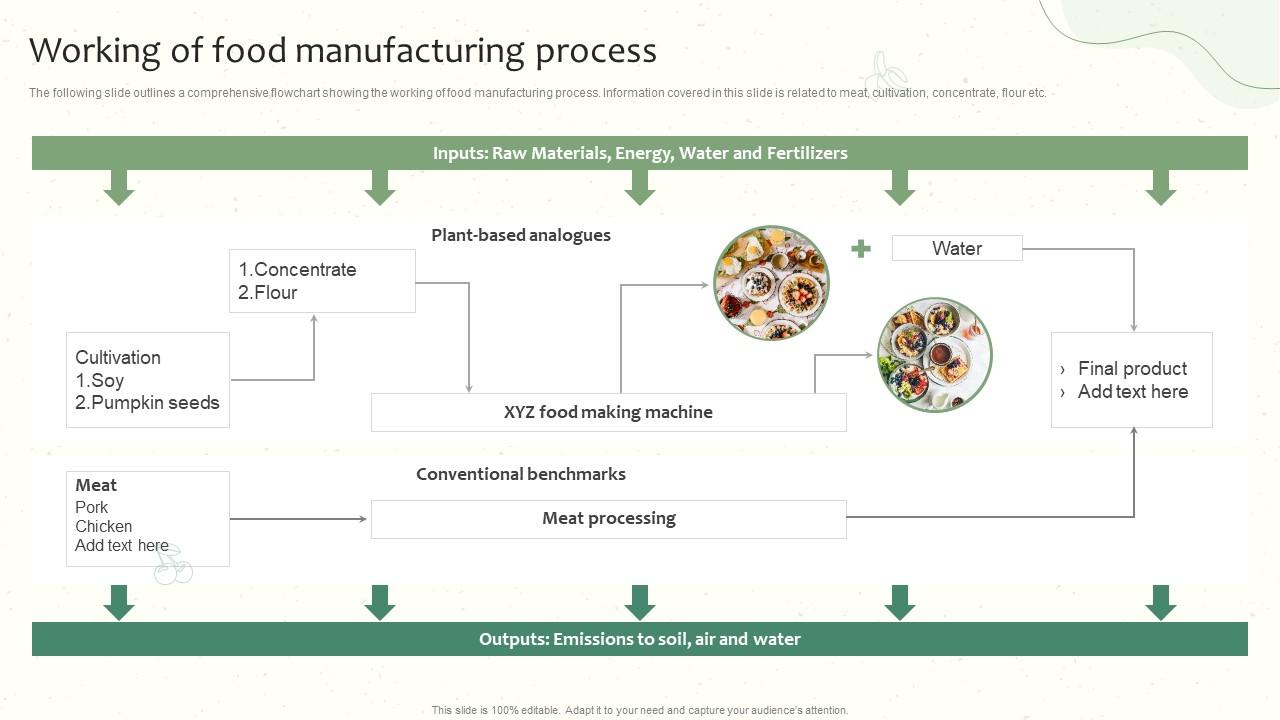

Incorporating eco-friendly practices into advanced manufacturing processes begins with item design. Designers can leverage simulation tools and virtual models to analyze how materials and methods impact the ecological system throughout the item life span. By identifying possible inefficiencies in the design phase, manufacturers can reduce material waste and energy consumption from the outset. This forward-thinking approach transforms product design into an integral aspect of eco-sensitivity, ensuring that the final items have minimal environmental impact.

Additionally, advanced manufacturing processes facilitate the adoption of closed-loop economy principles. By utilizing technologies such as additive manufacturing and waste recovery systems, factories can convert waste materials into new products, closing the loop in the manufacturing process. These advancements not only support sustainability goals but also create new commercial opportunities. As companies embrace these practices, they contribute to a more sustainable future while simultaneously boosting their market position in the marketplace.

Sustainable Materials and Practices

The integration of eco-friendly materials into item design is a cornerstone of smart factories. Such facilities utilize cutting-edge technologies to source and use materials that have a lower environmental footprint. Decomposable plastics, recycled metals, and organic textiles are becoming increasingly common in production processes. By choosing materials that can break down or be repurposed, intelligent factories are significantly reducing waste and promoting a closed-loop economy.

In addition to employing eco-friendly materials, smart factories also implement practices that enhance environmental responsibility. These may encompass energy-efficient machinery, water conservation systems, and waste minimization techniques. By optimizing operations and utilizing renewable energy sources, manufacturers can reduce their carbon footprint while maintaining productivity. This commitment to efficiency not only benefits the planet but also results in cost savings for companies.

Collaboration within supply chains is crucial for the success of eco-friendly manufacturing methods. Smart factories often partner with suppliers who share their commitment to sustainability, boosting the overall impact of their efforts. By ensuring that each link in the supply chain prioritizes sustainable practices, from raw material extraction to product delivery, companies can create truly eco-friendly products. This holistic approach to product design and manufacturing redefines what it means to be sustainable in today's economy.