Uncoiling Brilliance The Art and Science of Wire Winding That Powers Our World 🔌🌀

The hum of industry, the pulse of innovation, the invisible threads connecting our modern lives—wire winding sits at the heart of it all. Imagine a world without electric motors whirring in your appliances, transformers silently stepping voltage up or down, or the intricate coils in medical MRI machines. That world wouldn’t just stall; it’d unravel. Welcome to the unsung hero of engineering: wire winding.

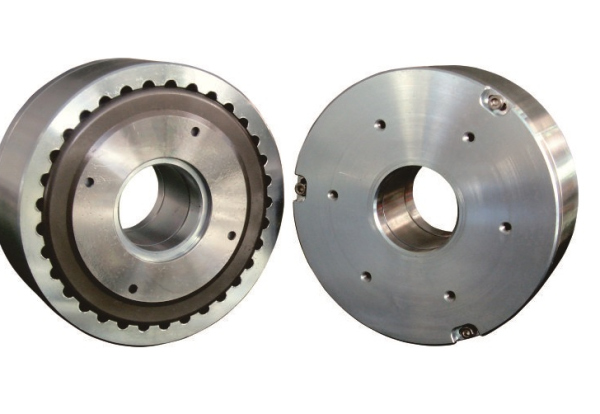

At its core, wire winding is the meticulous process of wrapping conductive wire—copper, aluminum, or specialized alloys—around a core or bobbin. But calling it “winding” is like calling the Sistine Chapel “a paint job.” hysteresis brakes where tension, speed, angle, and material dance together to create functional art.

### Why Wire Winding Is Everywhere (Seriously, Everywhere) 🌎🔋

From the smartphone in your pocket to wind turbines slicing through coastal skies, wound components are the silent workhorses. Consider:

- **Electric Motors**: Every rotation in your car’s power window or a factory’s conveyor belt relies on stator and rotor windings.

- **Transformers**: They step down voltage for your laptop charger and step it up for cross-country power lines—all via copper coils.

- **Medical Tech**: MRI machines use superconducting windings cooled to near absolute zero to map the human body.

- **Renewable Energy**: Solar inverters and wind generator coils turn nature’s raw power into usable electricity.

Without optimized winding, efficiency plummets. Heat builds. Devices fail. That’s why engineers lose sleep over \"fill factors\" and \"creepage distances.\"

### The Ballet of Precision: How Winding Machines Make Magic 🤖🎭

Gone are the days of hand-cranked coils (though artisans still exist for bespoke projects). hysteresis brakes ’s winding machines blend robotics, software, and tactile finesse:

1. **Linear Winding**: Wire feeds straight onto rotating bobbins—ideal for simple solenoids or relays.

2. **Flyer Winding**: A rotating arm orbits the core, perfect for toroidal shapes like those in compact power supplies.

3. **Needle Winding**: For ultra-fine, high-density coils in hearing aids or aerospace sensors, where a needle threads wire through tight spaces.

Modern systems use AI vision to detect micro-frays and adaptive tension control to handle silk-thin wires. One glitch, and a $50,000 transformer core becomes scrap.

### Material Matters: Beyond Copper and Plastic 🧪✨

While copper dominates for conductivity, innovation surges:

- **Litz Wire**: Braided strands reduce “skin effect” losses in high-frequency applications (think EV chargers).

- **Square/Rectangular Wire**: Boosts packing density in motors, squeezing 15% more power into the same space.

- **High-Temp Superconductors**: Wires cooled with liquid nitrogen that move power with near-zero loss—game-changers for grid efficiency.

Insulation isn’t just plastic sleeves anymore. Polyimide films withstand 400°C+ in jet engines, while nanomaterials repel moisture in deep-sea robotics.

### The Human Touch in an Automated World ✋❤️

Automation handles 95% of winding tasks, but the final 5% demands craft:

- A technician tuning tension by ear because the wire “sings” differently at 0.2 Newtons.

- Prototype coils wound by hand for Formula 1 battery packs, where every gram counts.

- Artisanal audio transformers for vinyl purists, where hand-layered windings reduce electromagnetic “haze.”

As Maria Gonzalez, a 30-year winding veteran at Delta Electrics, puts it: “The machine sets the stage, but you feel the wire’s soul. It tells you when it’s happy.”

### Sustainability: The Silent Revolution ♻️🌱

Wire winding isn’t just efficient—it’s evolving to *be* efficiency:

- Recycled copper now meets 80% of demand, slashing mining impacts.

- Water-based insulation coatings replace toxic solvents.

- Digital twin simulations predict wear, reducing factory waste by 40%.

Leading companies now track “carbon per coil”—because green energy needs green manufacturing.

### Tomorrow’s Windings: Where We’re Headed 🚀🔮

1. **3D-Printed Coils**: Additive manufacturing builds windings layer-by-layer inside cores, enabling shapes impossible with spindles.

2. **Quantum Computing**: Ultraprecise superconducting coils stabilize qubits at milli-Kelvin temperatures.

3. **Bio-Integrated Devices**: Dissolvable windings for temporary medical implants that monitor healing, then vanish.

The future isn’t just automated; it’s intelligent. Imagine self-calibrating winders that learn from each coil, or blockchain-tracked materials ensuring ethical sourcing.

### Why Expertise Wins 🏆💡

In a market flooded with cookie-cutter solutions, true mastery lies in understanding nuance:

- How nylon versus polyester insulation affects resonant frequency in RF coils.

- Why winding clockwise vs. counterclockwise matters in canceling electromagnetic interference.

- When to choose random vs. orthocyclic winding patterns for thermal stability.

This isn’t assembly. It’s alchemy.

### Wrap-Up: Connect With Purpose 🌟🔌

Wire winding is more than loops of metal. It’s the nexus of physics, craftsmanship, and ambition—a discipline where a fraction of a millimeter shifts megawatts of energy or decodes brain activity. Whether you’re designing the next electric aircraft or a pacemaker that fits in a walnut, remember: every revolution starts with a single turn.

So, next time you charge your phone or hear an ambulance’s siren, tip your hat to the coiled wonder inside. It’s not just wire. It’s wired for brilliance.

Ready to reimagine your winding workflow? Let’s spin the future, together.