Shielded Cable for Precision Instruments Ensuring Accuracy and Reliability

Introduction

In the world of precision instruments, accuracy and reliability are paramount. These instruments are used in various industries such as aerospace, medical, automotive, and telecommunications, where precise measurements and data acquisition are essential. One critical component that plays a significant role in ensuring the accuracy and reliability of these instruments is shielded cable. Shielded cables are specifically designed to protect sensitive signals from electromagnetic interference (EMI) and radio frequency interference (RFI), which can cause disruptions and inaccuracies in data transmission. In this article, we will explore the importance of shielded cable in precision instruments, its construction, benefits, and applications.

Importance of Shielded Cable in Precision Instruments

Precision instruments rely on accurate and reliable data to perform their intended functions effectively. Any interference or noise in the signals can lead to incorrect measurements, malfunctions, or data corruption, compromising the overall performance of the instrument. Shielded cables are designed to mitigate the effects of EMI and RFI, which are common sources of signal interference in electronic systems.

EMI and RFI can be generated by various sources such as power lines, motors, electronic devices, and radio signals. These unwanted electromagnetic fields can induce voltages and currents in neighboring conductors, leading to signal distortion and degradation. In precision instruments, even minor deviations in the signal can have significant consequences, making it crucial to use shielded cables to maintain signal integrity.

Shielded cables provide a physical barrier between the conductors carrying the signal and the external electromagnetic fields. The shield, typically made of a conductive material such as copper or aluminum, acts as a Faraday cage, effectively blocking out external interference and preventing it from affecting the signal. By shielding the cables, precision instruments can operate in noisy environments without compromising the accuracy of their measurements.

Construction of Shielded Cable

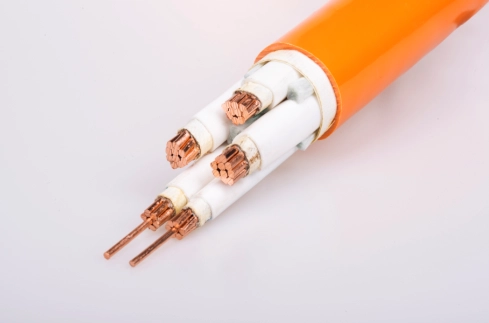

Shielded cables are constructed with multiple layers of materials to provide both mechanical protection and electromagnetic shielding. The basic components of a shielded cable include the conductors, insulation, shielding, and jacket. Each of these components plays a crucial role in ensuring the overall performance and durability of the cable.

1. Conductors: The conductors are the core components of the cable that carry the electrical signals. In shielded cables, the conductors are typically made of copper or aluminum due to their excellent conductivity and flexibility. The size and configuration of the conductors depend on the specific requirements of the application, such as signal frequency, current capacity, and voltage rating.

2. Insulation: Insulation is used to separate the conductors from each other and from the shield. It prevents short circuits and ensures the integrity of the signal transmission. The insulation material is chosen based on factors such as temperature resistance, dielectric strength, and flexibility. Common insulation materials used in shielded cables include PVC (Polyvinyl Chloride), PE (Polyethylene), and FEP (Fluorinated Ethylene Propylene).

3. Shielding: The shielding layer is the key component that provides protection against EMI and RFI. There are two main types of shielding commonly used in shielded cables: foil shielding and braided shielding. Foil shielding consists of a thin layer of metallic foil wrapped around the conductors, while braided shielding consists of woven strands of conductive material such as copper or aluminum.

4. Jacket: The outer jacket of the cable provides mechanical protection and insulation from environmental factors such as moisture, chemicals, and abrasion. The jacket material is chosen based on the intended application and operating conditions. Common jacket materials include PVC, PUR (Polyurethane), and TPE (Thermoplastic Elastomer).

Benefits of Shielded Cable for Precision Instruments

Shielded cables offer several benefits that make them ideal for use in precision instruments. Some of the key benefits include:

1. Electromagnetic Interference Protection: Shielded cables effectively block out external electromagnetic fields, preventing interference and ensuring the integrity of the signal transmission. This protection is crucial in precision instruments where accuracy and reliability are paramount.

2. Signal Integrity: By minimizing signal distortion and noise, shielded cables help maintain the integrity of the signal throughout the transmission path. This results in accurate measurements and reliable data acquisition, essential for the proper functioning of precision instruments.

3. Noise Immunity: Shielded cables are designed to minimize the impact of external noise sources such as power lines, motors, and electronic devices. This noise immunity ensures that the signals remain unaffected by external disturbances, leading to stable and consistent performance of the instrument.

4. Durability: Shielded cables are built to withstand harsh environments and mechanical stress, making them highly durable and reliable. The multiple layers of protection provided by the cable construction ensure long-term performance and minimal maintenance requirements.

5. Flexibility: Despite their robust construction, shielded cables are flexible and easy to install in various applications. The flexibility of the cables allows for easy routing and installation, making them suitable for complex and space-constrained environments.

Applications of Shielded Cable in Precision Instruments

Shielded cables find extensive use in a wide range of precision instruments across different industries. Some common applications of shielded cable in precision instruments include:

1. Medical Devices: Shielded cables are used in medical devices such as MRI machines, ultrasound equipment, and patient monitoring systems. These devices require precise measurements and data transmission, which can be affected by external electromagnetic interference. Shielded cables ensure reliable signal transmission and accurate readings in medical applications.

2. Aerospace and Defense: In aerospace and defense applications, precision instruments such as radar systems, navigation equipment, and avionics rely on shielded cables for secure and accurate data transmission. The high levels of electromagnetic interference in these environments necessitate the use of shielded cables to maintain signal integrity.

3. Telecommunications: Telecommunication systems, including data centers, networking equipment, and telecommunication towers, use shielded cables to ensure reliable signal transmission and data connectivity. The cables protect sensitive signals from external interference, allowing for uninterrupted communication and data exchange.

4. Automotive Industry: Precision instruments used in automotive applications, such as engine control units, sensors, and diagnostic equipment, require shielded cables to prevent electromagnetic interference from affecting the performance of the vehicle. Shielded Control cable applications help maintain the accuracy of measurements and ensure the reliability of automotive systems.

5. Industrial Automation: In industrial automation systems, precision instruments such as PLCs (Programmable Logic Controllers), sensors, and robotic systems use shielded cables to safeguard signal integrity and prevent disruptions in data transmission. The cables enable precise control and monitoring of industrial processes, enhancing efficiency and productivity.

Conclusion

Shielded cables play a critical role in ensuring the accuracy and reliability of precision instruments across various industries. By providing protection against electromagnetic interference, shielded cables help maintain signal integrity, minimize noise, and ensure stable data transmission. The construction, benefits, and applications of shielded cables make them essential components in precision instruments where precise measurements and data acquisition are paramount. As technology continues to advance, the demand for shielded cables in precision instruments is expected to grow, emphasizing the importance of reliable signal transmission in achieving optimal performance and efficiency.