Under Pressure: How Exactly Hermetically Sealed Connectors Guarantee Dependability

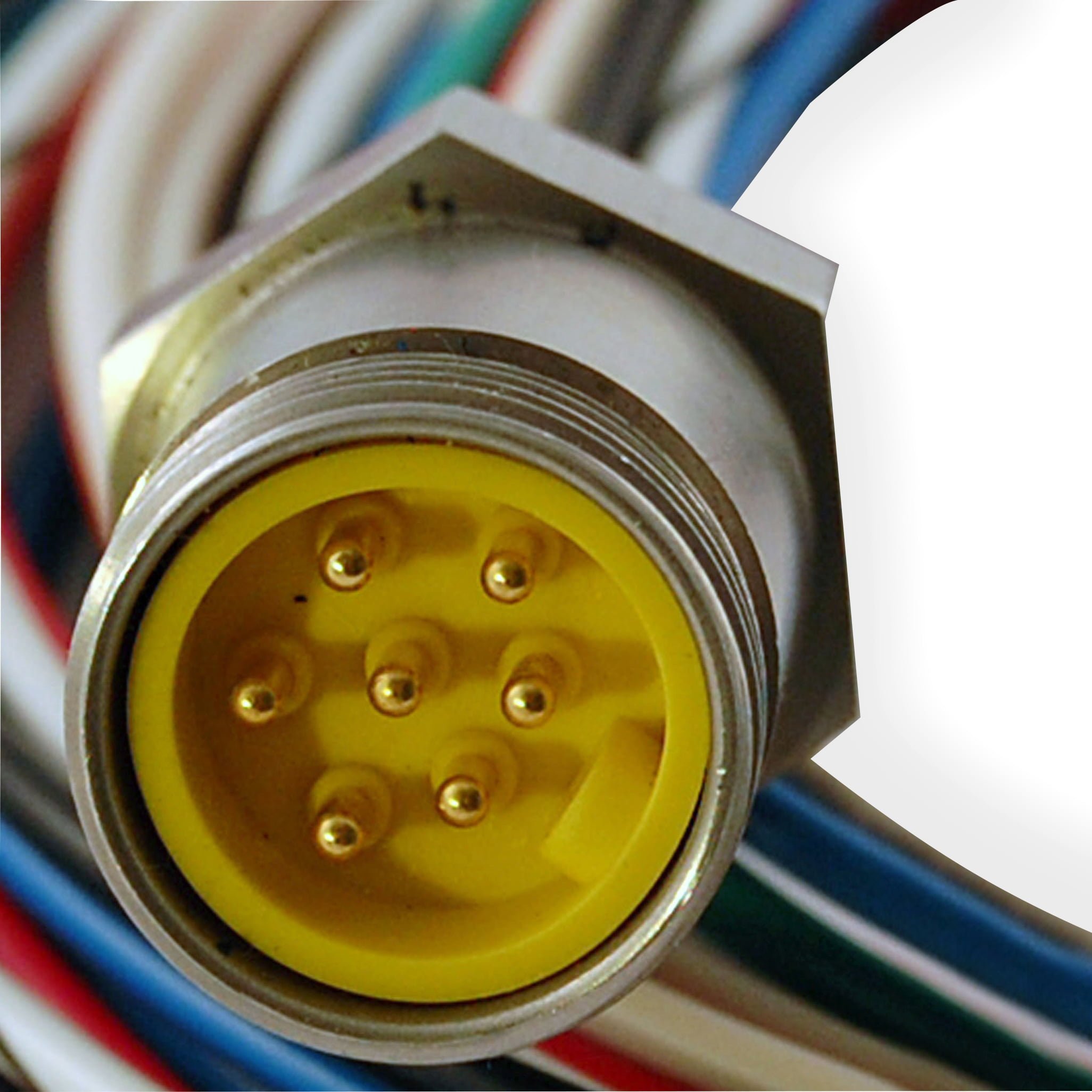

Within a environment where technology continues to progress at an unprecedented rate, the consistency of electronic elements is increasingly important than before. Hermetic sealed connectors have arisen as a essential solution for industries that necessitate resilient functionality in difficult environments. These devices are engineered to offer a secure and sealed barrier, protecting sensitive electronic systems from moisture, particles, and various environmental elements that could lead to malfunction.

As we explore into the mechanics of sealed sealed devices, it turns out clear how their distinctive design and features contribute to their reliability. By creating a barrier against impurities, these connectors ensure that mechanisms remain operational even in extreme environments, making them indispensable for uses in aviation, defense, and medical instruments. Grasping how airtight sealed devices function assists illuminate their significance in preserving the reliability and longevity of essential electronic components.

Benefits of Hermetic Connectors

Sealed hermetic connectors provide exceptional safeguarding from external conditions that can jeopardize the integrity of electrical interfaces. By creating a secure and tight seal, these connectors stop water, debris, and various pollutants from infiltrating the connection areas. This is especially crucial in situations exposed to harsh conditions such as extreme temperatures, wet conditions, and corrosive environments, ensuring that connections remain operational over an extended period.

A further significant advantage of sealed hermetic connectors is their ability to maintain electrical efficiency under varying pressure conditions. These connectors are designed to function reliably in both vacuum and pressurized environments. This feature is crucial for applications in the aerospace sector, military, and medical fields where maintaining functionality under pressure variations is essential for security and operational reliability.

In addition, hermetic sealed connectors contribute to the overall longevity and robustness of electronic systems. By minimizing the risk of wear and tear and reducing the chances of failure due to environmental stressors, these connectors enhance the life cycle of devices. This reliability not only lowers repair expenses but also improves user confidence in the performance of systems where these connectors are implemented.

Applications in Severe Environments

Hermetically sealed connectors are vital in sectors where exposure to extreme conditions could jeopardize the functionality of traditional connectors. In space, for example, these connectors are used to make sure that critical electronic devices remains operational despite harsh atmospheric pressures and variations in temperature. The ability of hermetic seals to keep moisture, dust, and corrosive elements at bay makes them necessary for avionics systems, where dependability is key.

Likewise, in the oil and gas industry, hermetic sealed connectors play a critical role in underwater equipment and drilling systems. These connectors protect against the intrusion of seawater and other hazardous substances that can compromise electric connections and lead to malfunction. By employing hermetic sealing technologies, companies can enhance the durability and functionality of their systems, ensuring smooth operations in some of the most challenging environments on Earth.

In defense applications, hermetic sealed connectors are employed in machinery that must operate in harsh temperatures and polluted surroundings. The durability of these connectors is essential for maintaining communication and control systems in combat scenarios. By preventing moisture and foreign particles from infiltrating vital components, hermetic sealed connectors contribute to operational readiness and mission success, highlighting their importance in high-stakes applications.

Technological Advancements in Sealant Techniques

The advancement of airtight sealed connectors has significantly evolved due to improvements in materials and production processes. Modern sealing techniques often incorporate high-performance elastomers and ceramics that provide excellent resistance against environmental factors such as moisture, dust, and harsh temperatures. These materials improve the durability and reliability of connectors, ensuring that they maintain their functionality even in the harshest conditions.

One of the main innovations in this field is the use of innovative bonding methods that create stronger and highly durable seals. Techniques like laser welding and thermal compression bonding allow for exact control over the sealing process, ensuring that the hermetic barriers are deployed uniformly. This not only improves the overall integrity of the connectors but also optimizes production efficiency, lessening waste and costs associated with traditional sealing methods.

In addition to robust materials and cutting-edge sealing techniques, the integration of smart technologies within hermetic sealed connectors is gaining traction. Sensors and tracking systems can now be integrated within the connectors to provide instant feedback on their condition and performance. This level of monitoring helps identify potential issues before they lead to failure, offering a proactive approach to maintenance and further enhancing the reliability of critical systems where these hermetic sealed connectors are used.