Diesel Generator for Humidity Testing A Comprehensive Guide

Introduction

Humidity testing is a crucial process in various industries, such as electronics, pharmaceuticals, food, and automotive, to ensure the quality and reliability of products in different environmental conditions. One of the key components used in humidity testing setups is a diesel generator. In this article, we will explore the importance of diesel generators in humidity testing, their working principles, key features to consider when choosing one, and some best practices for their maintenance and operation.

Importance of Diesel Generators in Humidity Testing

Humidity testing involves subjecting products or materials to controlled levels of humidity to assess their performance and durability under different environmental conditions. This testing is essential to simulate real-world scenarios and ensure that products can withstand high humidity levels without degradation. To create and maintain these controlled humidity levels, specialized equipment is required, including humidifiers, dehumidifiers, and environmental chambers. Among these, diesel generators play a crucial role in providing reliable power supply to run the humidity testing equipment.

Diesel generators are preferred for humidity testing setups due to their robustness, efficiency, and ability to provide continuous power for extended periods. Unlike electric generators that rely on the grid power supply, diesel generators are independent power sources that can operate autonomously, making them ideal for critical applications like humidity testing where power interruptions can lead to data loss or equipment damage.

Working Principles of Diesel Generators in Humidity Testing

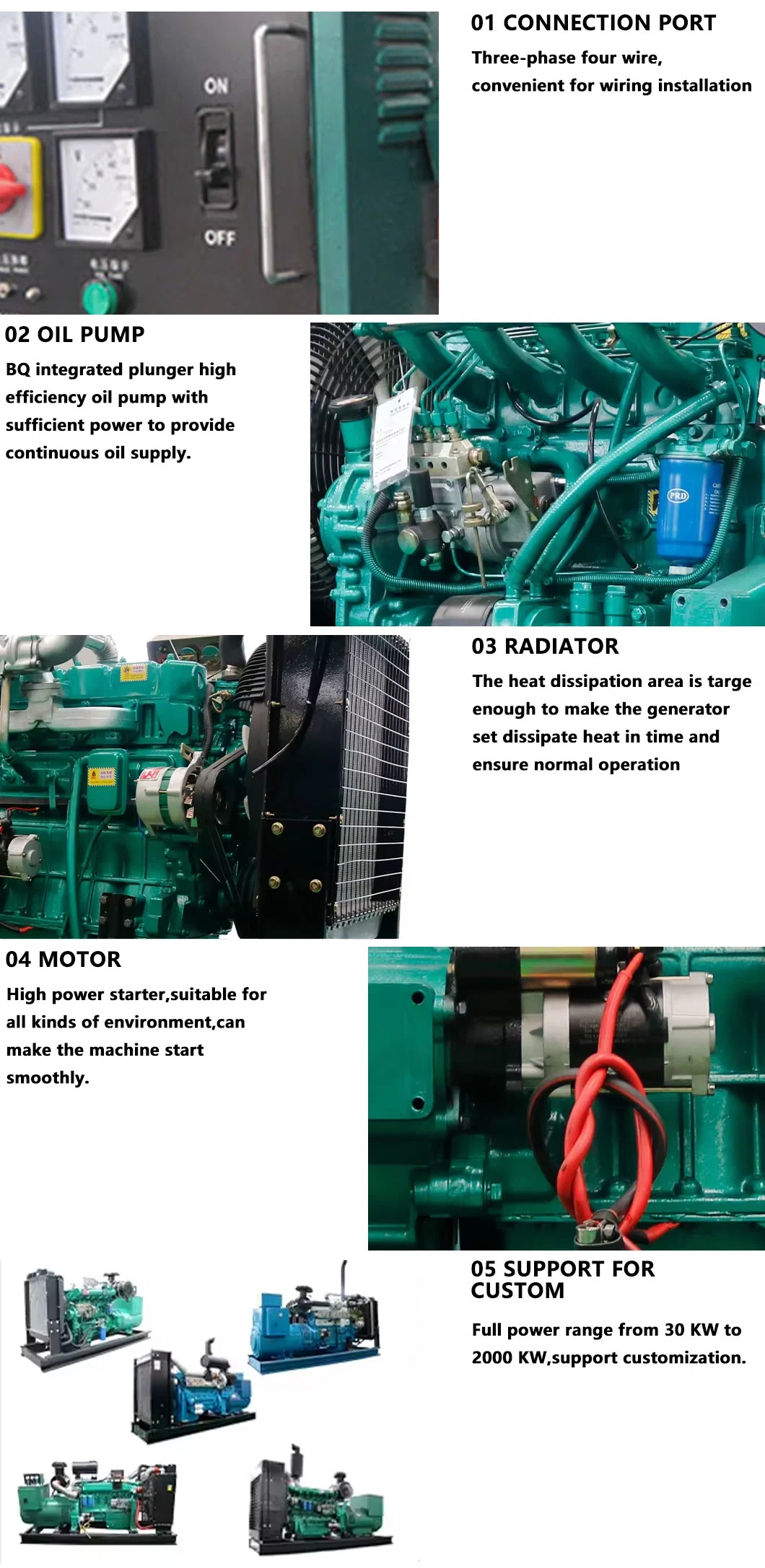

A diesel generator operates on the principle of converting diesel fuel into mechanical energy through combustion. The basic components of a diesel generator include an engine, alternator, fuel system, cooling system, and control panel. When the generator is started, the diesel fuel is injected into the engine's combustion chamber, where it mixes with compressed air and ignites, generating mechanical energy. This energy is then converted into electrical energy by the alternator, which produces the required power output to run the humidity testing equipment.

In a humidity testing setup, the diesel generator is connected to the main power distribution panel, which supplies electricity to the environmental chambers, humidifiers, dehumidifiers, and other testing equipment. The generator's control panel monitors the power output, engine temperature, fuel levels, and other parameters to ensure smooth and reliable operation throughout the testing process. Diesel generators are designed to handle varying loads and provide stable power supply, making them essential for maintaining consistent humidity levels in testing environments.

Key Features to Consider When Choosing a Diesel Generator for Humidity Testing

When selecting a diesel generator for humidity testing applications, several key features should be taken into consideration to ensure optimal performance and reliability. These features include:

1. Power Output: The generator's power output should be sufficient to meet the electricity demand of the humidity testing equipment and maintain stable humidity levels in the testing environment. It is essential to calculate the total power requirements of all connected devices to determine the appropriate generator size.

2. Fuel Efficiency: Diesel generators should be fuel-efficient to minimize operating costs and reduce environmental impact. Look for generators with advanced fuel injection systems, efficient combustion engines, and automatic load management features to optimize fuel consumption.

3. Noise Level: Humidity testing setups are often located in laboratories or manufacturing facilities where noise levels must be kept to a minimum. Choose 500kw diesel generator for remote scientific projects with soundproofing measures, such as insulated enclosures and mufflers, to reduce noise emissions during operation.

4. Durability and Reliability: Diesel generators for humidity testing should be built to withstand continuous operation in harsh environmental conditions. Select generators from reputable manufacturers known for their quality construction, robust components, and reliable performance.

5. Maintenance Requirements: Regular maintenance is essential to ensure the long-term reliability of a diesel generator. Choose a model with user-friendly maintenance features, such as easy access to filters, oil change mechanisms, and diagnostic tools for troubleshooting common issues.

Best Practices for Diesel Generator Maintenance and Operation in Humidity Testing

To maximize the performance and lifespan of a diesel generator used in humidity testing, the following best practices should be followed:

1. Regular Maintenance: Schedule routine maintenance tasks, such as oil and filter changes, fuel system inspections, and coolant checks, as recommended by the manufacturer. Keep a detailed maintenance log to track service intervals and identify any potential issues early on.

2. Load Testing: Periodically conduct load tests on the generator to ensure that it can handle the full power requirements of the humidity testing equipment. Load testing helps identify any performance issues and ensures that the generator can operate efficiently under varying load conditions.

3. Fuel Quality: Use high-quality diesel fuel with the appropriate additives to prevent contamination and reduce the risk of engine damage. Store fuel in clean, well-ventilated tanks away from direct sunlight and regularly test for water or sediment buildup.

4. Cooling System Maintenance: Monitor the generator's cooling system regularly to prevent overheating and ensure optimal engine performance. Inspect coolant levels, hoses, and radiator fins for any signs of wear or leakage and clean the cooling system as needed.

5. Emergency Preparedness: Develop an emergency response plan in case of a power outage or generator failure during humidity testing. Keep spare parts, fuel reserves, and backup power sources on hand to minimize downtime and maintain testing continuity.

Conclusion

Diesel generators play a vital role in humidity testing setups by providing reliable power supply for environmental chambers, humidifiers, and dehumidifiers. Their robust construction, efficiency, and ability to operate autonomously make them indispensable for maintaining controlled humidity levels in testing environments. When selecting a diesel generator for humidity testing, consider key features such as power output, fuel efficiency, noise level, durability, and maintenance requirements to ensure optimal performance and reliability. By following best practices for maintenance and operation, you can maximize the lifespan of your diesel generator and ensure uninterrupted testing processes.