Exploring the Importance of Tensile Strength in PV Cables

Introduction

Photovoltaic (PV) systems play a crucial role in harnessing renewable energy from the sun. These systems consist of various components that work together to generate electricity, including PV panels, inverters, and cables. While much attention is given to the efficiency of the panels and inverters, the importance of PV cable tensile strength is often overlooked. In this article, we will delve into the significance of tensile strength in PV cables, its role in ensuring the reliability and longevity of solar installations, and the factors that influence this critical property.

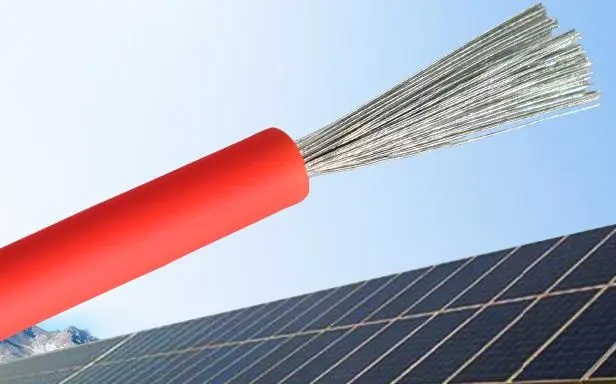

Understanding PV Cables

PV cables are an essential component of solar power systems, responsible for transmitting the electricity generated by the PV panels to the inverters and ultimately to the electrical grid. These cables are subjected to a range of environmental conditions, including temperature variations, UV exposure, moisture, and mechanical stress. As such, they must be designed to withstand these challenges while maintaining electrical conductivity and mechanical integrity.

Tensile Strength: The Key to Reliability

Tensile strength is a critical mechanical property of PV cables that measures their ability to withstand pulling forces without breaking. In the context of solar installations, where cables are often exposed to external forces such as wind, snow loads, and installation stresses, tensile strength plays a crucial role in ensuring the reliability and safety of the system. Cables with inadequate tensile strength may fail under these forces, leading to system downtime, electrical faults, and potential safety hazards.

Factors Influencing Tensile Strength

Several factors influence the tensile strength of PV cables, including the materials used in their construction, the design of the cable, and the manufacturing process. Common materials used in PV cables include copper and aluminum conductors, as well as insulation and jacketing materials such as polyethylene (PE) and cross-linked polyethylene (XLPE). Control cable grounding of these materials and their compatibility with each other can significantly impact the tensile strength of the cable.

Additionally, the design of the cable, including the number of conductors, the diameter of the wires, and the configuration of the insulation layers, can influence its tensile strength. Cables designed with a focus on mechanical robustness and durability are more likely to exhibit higher tensile strength values compared to those with suboptimal designs.

Furthermore, the manufacturing process plays a crucial role in determining the tensile strength of PV cables. Factors such as the extrusion process, quality control measures, and testing procedures can all affect the final mechanical properties of the cable. Manufacturers that adhere to strict quality standards and invest in advanced production techniques are more likely to produce cables with superior tensile strength and overall performance.

Importance of Compliance with Standards

In the solar industry, adherence to international standards and regulations is paramount to ensure the quality and safety of PV cables. Organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established specific standards that define the requirements for PV cables, including tensile strength values. Compliance with these standards not only ensures the reliability of the cables but also facilitates interoperability and compatibility with other system components.

Testing and Quality Assurance

To verify the tensile strength of PV cables and ensure their compliance with industry standards, manufacturers conduct rigorous testing procedures during the production process. Tensile strength tests involve subjecting the cable to increasing tensile forces until it reaches its breaking point, allowing manufacturers to determine the maximum load the cable can withstand. These tests are essential for quality assurance and provide valuable data on the mechanical performance of the cable.

In addition to tensile strength tests, manufacturers may also perform other mechanical tests, such as bend tests, crush tests, and impact tests, to evaluate the overall durability and robustness of the cable. By subjecting the cable to simulated environmental conditions and mechanical stresses, manufacturers can identify potential weaknesses and make improvements to enhance the cable's performance and longevity.

Conclusion

In conclusion, tensile strength is a critical mechanical property of PV cables that plays a key role in ensuring the reliability, safety, and longevity of solar power systems. Cables with adequate tensile strength are better equipped to withstand external forces and environmental conditions, reducing the risk of system failures and electrical faults. By understanding the factors that influence tensile strength, adhering to industry standards, and conducting thorough testing and quality assurance procedures, manufacturers can produce high-quality PV cables that meet the demands of modern solar installations. Investing in cables with superior tensile strength is an investment in the efficiency and sustainability of solar energy systems for years to come.