Fuel Pressure Regulators: Balancing Pressure for Peak Performance

Fuel pressure regulators play a crucial role in the performance of internal combustion engines. They are responsible for maintaining the optimal fuel pressure in the fuel system, ensuring that the engine receives a consistent supply of fuel for efficient combustion. Without a properly functioning fuel pressure regulator, vehicles may experience a range of issues, from rough idle to poor acceleration, ultimately affecting overall performance.

Understanding how fuel pressure regulators work can help car enthusiasts and everyday drivers alike appreciate the complexity of their vehicles' fuel systems. These devices are not merely mechanical components; they are vital instruments in balancing fuel delivery, adapting to changes in engine demand, and ensuring that combustion occurs at peak efficiency. By diving deeper into the mechanics and functions of fuel pressure regulators , we can uncover the fundamental ways they contribute to both engine performance and fuel economy.

Understanding Fuel Pressure Regulators

Fuel pressure regulators play a crucial role in the performance of an engine by maintaining the optimal fuel pressure necessary for efficient combustion. They ensure that the fuel delivery system can adapt to varying engine demands, providing a consistent fuel flow regardless of changes in engine speed or load. By regulating the pressure in the fuel rail, these devices help achieve the right air-fuel mixture for different driving conditions, contributing to overall engine efficiency and power output.

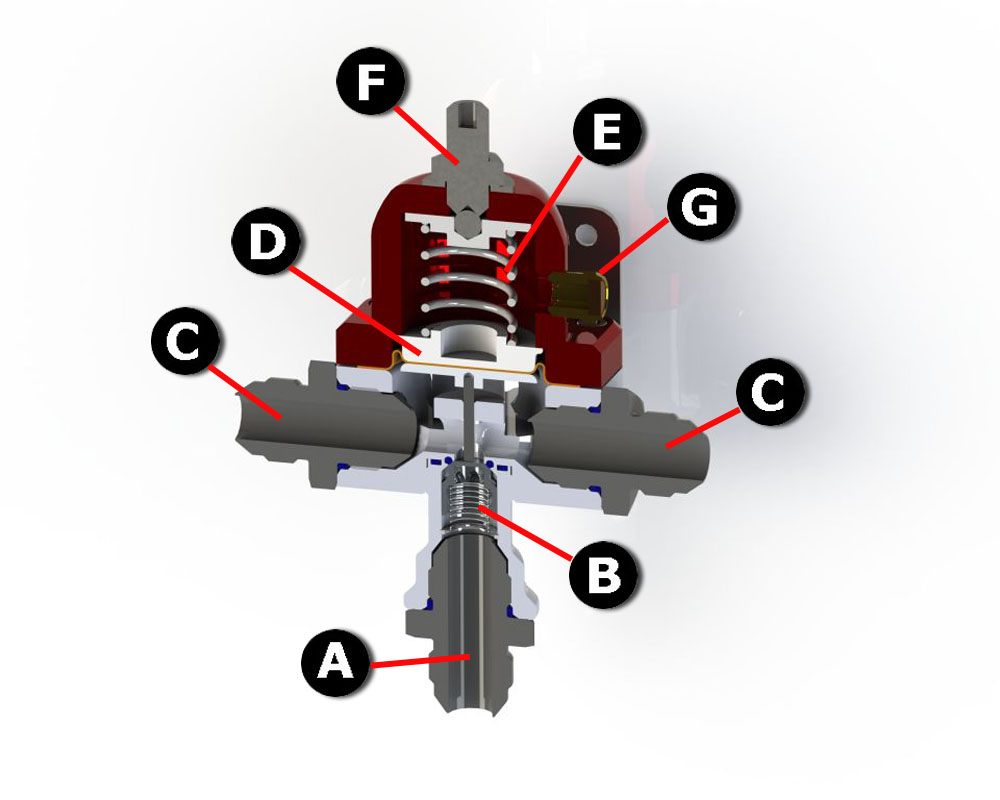

The operation of a fuel pressure regulator is relatively straightforward. It typically features a diaphragm that responds to changes in fuel pressure. When the fuel pressure rises above a predetermined level, the diaphragm opens a return path to the fuel tank, allowing excess fuel to flow back. Conversely, if the pressure drops, the diaphragm closes the return path, maintaining the necessary pressure within the fuel rail. This dynamic balance ensures that the engine receives the precise amount of fuel needed at any given moment.

There are two main types of fuel pressure regulators: manifold pressure reference and non-reference types. Manifold reference regulators adjust fuel pressure based on intake manifold pressure, which allows for improved performance in turbocharged or supercharged systems. Non-reference regulators maintain a steady pressure without accounting for changes in manifold pressure. Understanding the type of regulator your engine uses is essential for optimizing fuel delivery and achieving peak performance, making it a key component in the fuel management system.

Importance of Proper Pressure Balance

Maintaining the right fuel pressure is crucial for optimal engine performance. Fuel pressure regulators play a significant role in achieving this balance by ensuring that the fuel delivery system operates within specific pressure ranges. When the pressure is too high, it can lead to excessive fuel consumption, poor engine performance, and the risk of damaging components. Conversely, inadequate pressure can cause lean fuel mixtures, resulting in misfires and engine knocking. Thus, a well-functioning fuel pressure regulator is essential for both efficiency and reliability.

Proper pressure balance also has implications for emissions control. Engines that receive the correct fuel pressure are better able to combust fuel completely, reducing the production of harmful emissions. As vehicles become increasingly regulated for environmental impact, maintaining optimal fuel pressure becomes not just a performance issue but a compliance necessity. A fuel pressure regulator that ensures precise control helps vehicles meet emissions standards while supporting engine health.

Finally, the importance of pressure balance extends to long-term engine durability. Consistent and appropriate fuel pressure prevents undue stress on engine components, particularly injectors and fuel pumps. By ensuring that the fuel is delivered at the right pressure consistently, regulators help avoid premature wear and tear. This contributes to lower maintenance costs and a more extended lifespan for the engine, showcasing the critical role of fuel pressure regulators in overall vehicle performance and longevity.

Impact on Engine Performance

Fuel pressure regulators play a critical role in maintaining optimal fuel delivery to an engine, which directly influences its performance. When fuel pressure is regulated accurately, the engine can achieve the correct air-fuel mixture for combustion. This balance is essential for maximizing power output and ensuring efficient fuel usage. An inconsistent fuel pressure can lead to a range of performance issues, from rough idling to diminished acceleration, making the regulator a vital component in the overall engine performance equation.

Moreover, a well-functioning fuel pressure regulator helps to improve engine responsiveness. When the regulator responds promptly to changes in engine load during acceleration, it ensures that the engine receives the right amount of fuel at all times. This responsiveness enables quicker throttle response, allowing drivers to feel more in control of their vehicles. In contrast, a malfunctioning regulator can hinder performance by causing delays in fuel delivery, resulting in a sluggish driving experience.

Lastly, maintaining proper fuel pressure can also impact engine longevity. Consistent and accurate fuel delivery helps prevent problems such as carbon buildup, knocking, or misfiring, all of which can lead to engine damage over time. By ensuring that the fuel pressure regulator is functioning correctly, vehicle owners can not only enhance performance but also contribute to the overall health and lifespan of their engines.