Diesel Generators for Capacitive Loads Ensuring Reliable Power Supply

Introduction

Diesel generators play a crucial role in providing backup power during emergencies or in areas with unreliable grid electricity supply. These generators are commonly used in various applications, including industrial, commercial, and residential settings. One important aspect of diesel generators is their capability to handle capacitive loads, which are common in many electrical systems. In this article, we will explore the characteristics of diesel generators and their suitability for capacitive loads, as well as the challenges and considerations involved in using them for such applications.

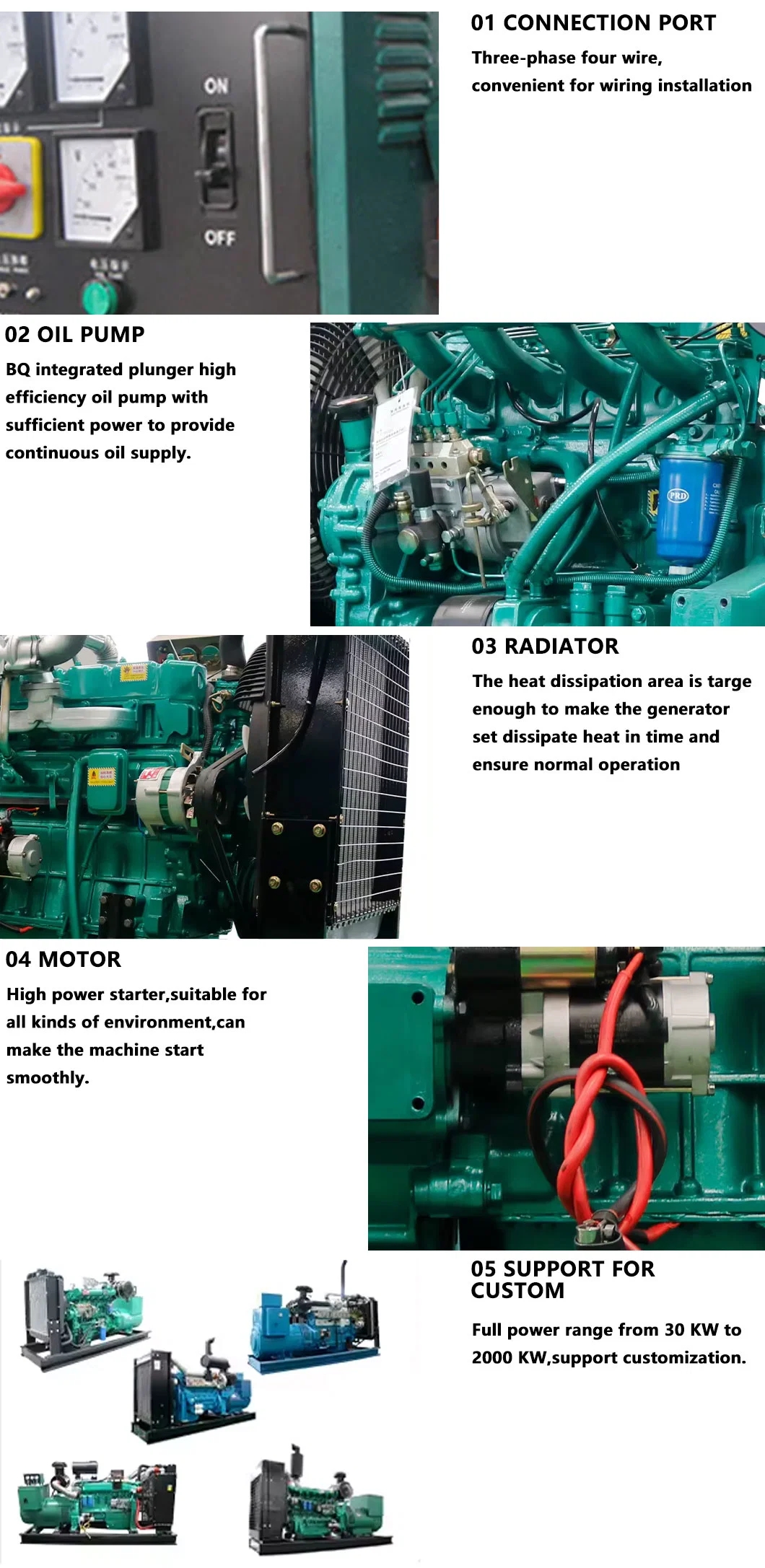

Understanding Diesel Generator For Sale are prime movers that convert diesel fuel into mechanical energy, which is then converted into electrical energy through an alternator. These generators are known for their robustness, reliability, and efficiency, making them a popular choice for standby and backup power generation. Diesel generators come in various sizes and configurations, ranging from portable units for residential use to large-scale systems for industrial applications.

One of the key advantages of diesel generators is their ability to provide high power output for extended periods, making them ideal for continuous or standby power applications. Diesel engines are also known for their durability and longevity, requiring minimal maintenance and offering a long service life. Additionally, diesel fuel is widely available and cost-effective, making diesel generators a practical choice for many users.

Capacitive Loads and Their Characteristics

Capacitive loads are a type of electrical load that exhibits a leading power factor, meaning that the current waveform leads the voltage waveform in phase. Capacitive loads are common in electrical systems that contain capacitors, such as power factor correction equipment, motor starting circuits, and electronic devices with capacitive components. Capacitive loads can cause issues such as voltage instability, power factor correction requirements, and harmonic distortion in the electrical system.

When a diesel generator is connected to a system with capacitive loads, it must be able to handle the unique characteristics of these loads effectively. Capacitive loads can cause the generator to experience voltage fluctuations, power factor issues, and harmonic distortions, which can impact the performance and reliability of the generator. Therefore, it is essential to understand how diesel generators interact with capacitive loads and what measures can be taken to mitigate potential problems.

Handling Capacitive Loads with Diesel Generators

Diesel generators are generally well-suited to handle capacitive loads, thanks to their robust design and reliable performance characteristics. However, there are certain considerations that need to be taken into account when operating a diesel generator in a system with capacitive loads. The following are some key factors to consider:

1. Voltage Regulation: Capacitive loads can cause voltage fluctuations in the electrical system, which can affect the performance of sensitive equipment. Diesel generators are equipped with voltage regulators that control the output voltage within a specified range, ensuring stable operation even under varying load conditions. Proper voltage regulation is essential to maintain the quality of power supplied to capacitive loads.

2. Power Factor Correction: Capacitive loads have a leading power factor, which means that they draw reactive power from the generator. Diesel generators must be capable of providing reactive power support to maintain the power factor within acceptable limits. Power factor correction equipment, such as capacitors or synchronous condensers, can be used in conjunction with the generator to improve the power factor and reduce the impact of capacitive loads.

3. Harmonic Distortion: Capacitive loads can introduce harmonic currents into the electrical system, leading to voltage distortion and increased losses. Diesel generators are designed to handle harmonic distortion to some extent, but additional filtering or mitigation measures may be necessary to ensure optimal performance. Filters, such as passive harmonic filters or active power conditioners, can be installed to reduce harmonic content and improve the quality of power supplied to capacitive loads.

4. Synchronization and Parallel Operation: In systems with multiple generators or grid connections, proper synchronization and parallel operation are essential to ensure stable and reliable power supply. Capacitive loads can affect the synchronization process by introducing phase shifts or frequency deviations, which can lead to instability or equipment damage. Diesel generators must be synchronized correctly and operated in parallel with other sources to maintain system stability and prevent issues with capacitive loads.

Challenges and Considerations

While diesel generators are well-suited for handling capacitive loads, there are some challenges and considerations that need to be addressed to ensure reliable operation and optimal performance. Some of the key challenges include:

1. Overloading: Capacitive loads can cause the generator to operate at higher than rated capacities, leading to overheating, voltage drops, and reduced efficiency. Diesel generators should be properly sized and rated to handle the expected load conditions, including capacitive loads, to prevent overloading and ensure safe operation.

2. Transient Response: Capacitive loads can introduce sudden changes in current demand, known as transients, which can impact the stability and performance of the generator. Diesel generators must have fast transient response capabilities to adjust to rapid load changes and maintain voltage stability. Advanced control systems and load-sharing mechanisms can help improve the transient response of the generator.

3. Maintenance and Monitoring: Regular maintenance and monitoring of diesel generators are essential to ensure their continued reliability and performance, especially in systems with capacitive loads. Proper maintenance practices, such as oil and filter changes, fuel system inspections, and cooling system checks, can help prevent downtime and extend the service life of the generator. Real-time monitoring of key parameters, such as voltage, frequency, and load levels, can also help identify potential issues and prevent failures.

Conclusion

Diesel generators are reliable and robust power generation devices that are well-suited for handling capacitive loads in various applications. By understanding the unique characteristics of capacitive loads and implementing appropriate measures, such as voltage regulation, power factor correction, and harmonic mitigation, diesel generators can provide stable and reliable power supply to systems with capacitive loads. Proper sizing, maintenance, and monitoring are essential to ensure the continued performance and longevity of diesel generators in capacitive load applications. Overall, diesel generators offer a viable solution for meeting the power requirements of systems with capacitive loads, ensuring uninterrupted operation and electrical system stability.