Beyond Basics: Investigating Sophisticated Features in Tailored Packing Equipment

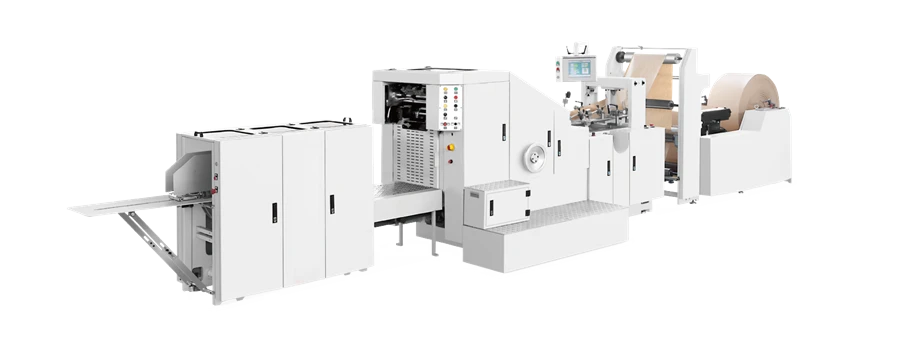

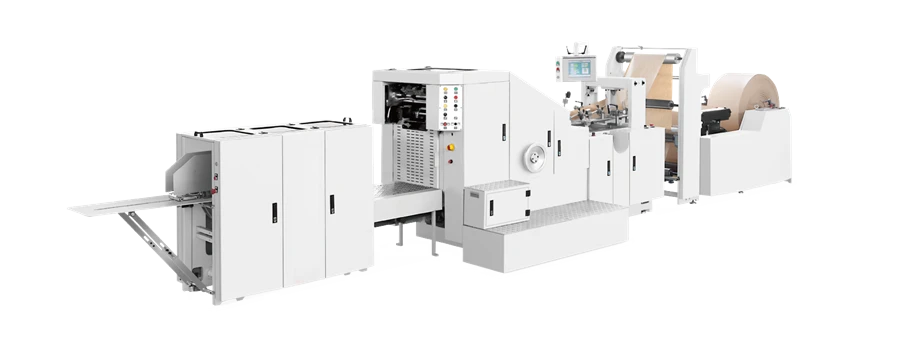

In competitive market, a demand for high-performing and trustworthy packaging solutions has prompted important advancements in bespoke packaging machinery. Businesses are no longer satisfied with simple machines that perform elementary tasks; they now seek specific equipment that can improve productivity, fit unique product shapes, and blend seamlessly into current production lines. As a result, bespoke packaging machinery manufacturers are responding to fulfill these developing demands by presenting new features and tailored solutions aimed at enhance packaging processes.

With intelligent automation and live data tracking to versatile design features, the progress in bespoke packaging machinery are transforming the landscape of packaging operations. By leveraging these innovative features, companies can boost their packaging efficiency, reduce waste, and ultimately deliver a higher-quality product to their customers. In this write-up, we will take a closer look into the sophisticated functionalities offered by custom packaging machinery manufacturers and how these developments can benefit your packaging operations.

Breakthroughs in Personalized Packaging

The field of bespoke packaging equipment has experienced significant transformation with recent innovations that meet multiple industry requirements. Cutting-edge techniques like AI and ML are enabling manufacturers to improve production processes and increase productivity. By embedding smart systems, packaging machinery can now monitor operational conditions in real-time, facilitating immediate adjustments that cut down on downtime and lower waste. This level of adaptability not only streamlines operations but also satisfies the rising requirement for customized solutions in different sectors.

Another intriguing trend is the development of eco-friendly packaging solutions within custom machinery. As businesses increasingly focus on environmental responsibility, manufacturers are reacting by creating equipment that handles green materials. Innovations such as biodegradable films and reuseable containers are turning out to be crucial, and machinery is being developed to process these materials without jeopardizing performance. This change not only meets consumer preferences but also aligns with global sustainability goals, leading the industry towards more sustainable practices.

Lastly, the inclusion of connected technology capabilities in custom packaging machinery marks a novel era of networking and information use. Intelligent machines integrated with sensors can connect with each other and central systems, providing valuable data analytics that help companies improve their packaging lines. This communication allows for preventive maintenance, lowering the risk of surprise failures and ensuring continuous operation. As the industry welcomes these innovative features, the role of custom packaging machinery continues to develop, turning into increasingly important for businesses looking to stay viable in a rapidly changing market.

Integrating Modern Technology in Machinery

The integration of advanced technology in tailored packaging solutions has truly changed the manner goods are packaged, ensuring effectiveness and accuracy. With the arrival of intelligent environmental sensors and automation, manufacturers are now equipped to streamline their workflows. These advanced technologies allow instantaneous monitoring of the packaging process, which minimizes idle time and decreases resources waste. By harnessing data analytics, organizations can derive insights into their production lines and make smart decisions to enhance efficiency.

An additional notable advancement is the integration of AI-driven algorithms. These solutions allow tailored packaging machinery to learn from historical data, enabling proactive maintenance and improving overall machinery dependability. As the system acclimates to different packaging needs, it offers manufacturers the flexibility to respond to diverse product lines without significant downtime for reconfiguration. This adaptability is crucial in the modern fast-paced market, where client expectations can shift quickly.

Moreover, the implementation of IoT (Internet of Things) improves connectivity between equipment and control systems. packaging machinery manufacturing enables companies to manage their businesses remotely, allowing improved control and administration. By utilizing jiandajx , companies can retrieve instant data from their production lines, enabling prompt modifications and enhancements. This extent of advanced capability boosts not only efficiency but also the quality of the product, making certain that items satisfy regulatory requirements and consumer demands.

Benefits of Tailored Solutions

Investing in tailored packaging solutions equipment delivers substantial gains for businesses looking to enhance their workflow. Personalized strategies are intentionally designed to meet the specific requirements of every client, making sure that the equipment aligns exactly with item specifications, packing methods, and business patterns. This extent of customization not just boosts efficiency but also lessens waste, providing a more sustainable strategy to manufacturing.

Furthermore, a Custom Packaging Machinery Manufacturer can embed cutting-edge technologies into the equipment, boosting automation and precision. Capabilities such as live monitoring, adjustable settings, and interoperability with multiple packaging materials can be incorporated, enabling businesses to maintain high-quality standards while responding to industry demands. This adaptability helps organizations stay in the game, as they can rapidly shift to adjust for new items or shifts in consumer preferences.

In conclusion, tailored packaging systems often lead to better ergonomics and safety for operators. By crafting systems that fits the particular environment and operator preferences, a Provider of Tailored Packaging Solutions can help minimize the risk of accidents and improve the overall safety environment. This attention on user-friendly design merely boosts employee morale but also enhances productivity by allowing staff to operate with greater effectively and effectively.