Implementing Quality Control Measures in Wire Bonding Operations

Introduction

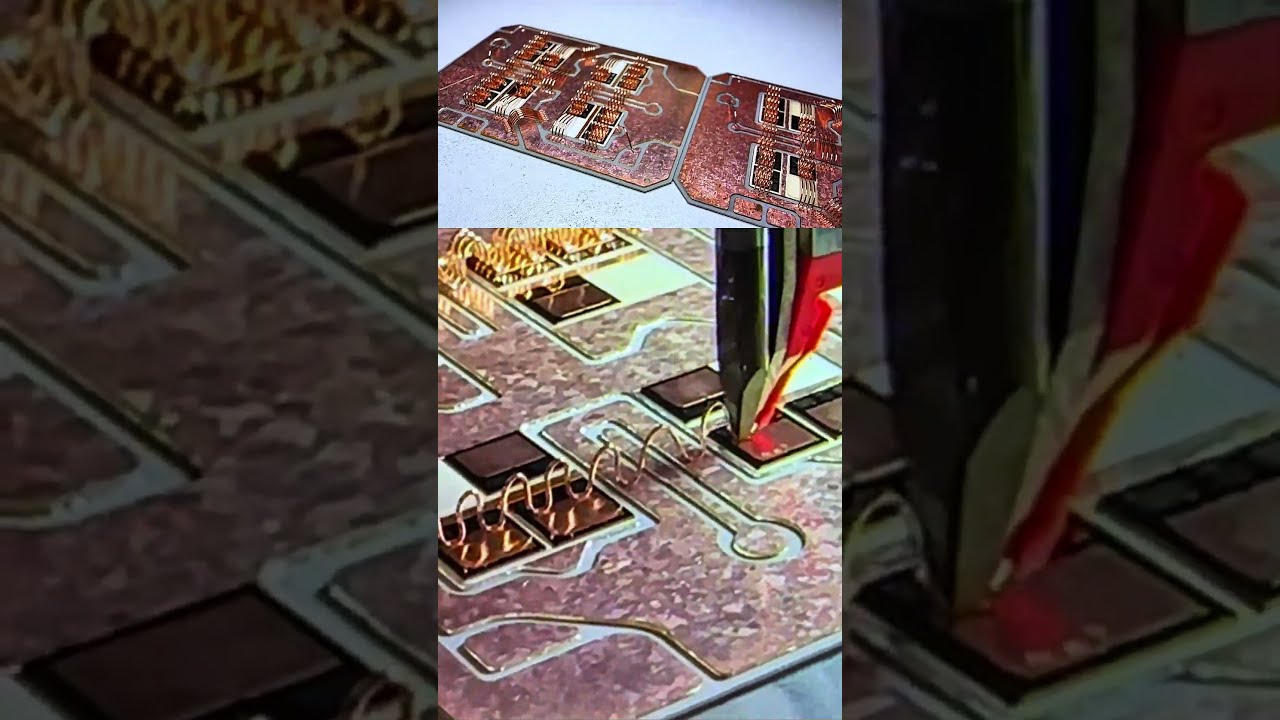

In the realm of electronics production, the twine bonding method performs a pivotal position in commencing legitimate electrical connections among semiconductor chips and their substrates. As science advances, so does the complexity of wire bonding operations. This complexity necessitates rigorous best keep watch over measures to make sure that operational potency, product reliability, and buyer delight. This article delves into the intricacies of twine bonding technological know-how, exploring the alternative approaches, device, and purposes whereas emphasizing the magnitude of excellent control.

What is Wire Bonding?

Wire bonding refers to a collection of strategies used to create electric connections between semiconductor units by way of skinny wires. These connections are a must-have for guaranteeing that digital components feature as supposed. The twine bonding approach encompasses varying systems consisting of ball bonding, wedge bonding, and ribbon bonding, each one with individual reward adapted to detailed applications.

Types of Wire Bonding Techniques

Ball Bonding Process: Involves growing a small ball at the conclusion of a twine by way of warm and ultrasonic potential beforehand attaching it to a bond pad. Applications: Commonly used for gold twine bonding in microelectronics. Wedge Bonding Process: Utilizes a wedge-formed instrument that presses the wire against the substrate. Applications: Effective for aluminum and copper wires in top-frequency programs. Ribbon Bonding Process: Employs flat ribbons in place of circular wires to ascertain connections. Applications: Ideal for vigor modules through their extended floor space. Thermosonic Bonding Combines warmth and ultrasonic calories to beef up bond power. Ultrasonic Bonding Uses ultrasonic vibrations without added warm for detailed components. Deep Access Wedge Bonding Enables bonding in hard-to-attain areas within intricate assemblies.

How Wire Bonding Works

The elementary concept in the back of wire bonding involves applying stress and warmth (or ultrasonic vigor) to enroll in metals via metallurgical interconnections. It starts with selecting top bonding wires—generally gold, aluminum, or copper—depending on their conductivity and mechanical homes.

Wire Bonding Equipment Overview

Wire Bonding Machines

Modern cord bonding operations remember closely on really expert machines tailored for the several sorts of bonds:

Manual Wire Bonding Machine: Designed for low-quantity construction; calls for human operation.

Semi-Automatic Wire Bonder: Offers partial automation to enhance productiveness at the same time still requiring operator input.

Fully Automatic Wire Bonder: Ideal for prime-volume manufacturing; these machines can operate independently with minimum supervision.

Bonding Tools

Each system is in a position with exact methods designed for premier functionality:

Bond Capillary Tool: Used to control and role the twine all over bonding.

Wedge Bonder Tool: Essential for reaching actual placements in wedge bonding strategies.

Implementing Quality Control Measures in Wire Bonding Operations

Quality management plays a important role in making certain that twine bonds are riskless and meet market principles. By enforcing systematic QC measures throughout the cord bonding approach, producers can substantially lessen defects and boost product efficiency.

Key Quality Control Techniques

Visual Inspection Regular inspections must be conducted to name any visual defects comparable to bond lifting or incomplete bonds. Non-Destructive Testing (NDT) Techniques like X-ray inspection allow producers to assess inner constructions with out harmful method. Pull Test Analysis Measures bond capability by way of applying a pressure unless failure happens; helps evaluate bond integrity. Shear Test Evaluation Similar to pull assessments however makes a speciality of horizontal shear forces acting on the bond interface. Environmental Controls Maintaining managed temperature and humidity levels all through construction can prevent oxidation-appropriate screw ups. Calibration Procedures Regular calibration of machines guarantees consistent functionality across distinct batches of items. Documentation Standards Keeping thorough history of each batch's parameters allows for monitoring back any defects or disorders that arise submit-manufacturing. Training Programs Continuous instruction systems for operators about most efficient practices in caliber assurance lend a hand mitigate human blunders in the course of operations. Supplier Quality Assurance Establish partnerships with authentic providers who adhere to strict textile high-quality requisites reduces negative aspects linked to inferior material.

FAQs

FAQ 1: What are frequent topics encountered in cord bonding?

Common complications embody bond lifting, heel cracks, oxidation of bond pads, incomplete bonds, and illness in the course of creation strategies.

FAQ 2: How do you examine if a bond is strong sufficient?

Bond potential will also be evaluated the use of pull exams or shear checks wherein controlled forces are implemented unless failure occurs; consequences imply even if bonds meet required necessities.

FAQ 3: What fabrics are basically used for cord bonds?

Gold, aluminum, copper, and silver are many times used ingredients with the aid of their superb conductivity residences; collection most likely is dependent on program specifications like thermal control or charge considerations.

FAQ 4: Why is environmental management essential in twine bonding?

Proper environmental controls support mitigate disadvantages linked to moisture absorption and oxidation that could compromise bond integrity through the years; it really is in particular necessary whilst working with touchy formulation like MEMS or RF modules.

FAQ five: Can I operate manual inspections quite simply?

Yes! However, depending exclusively on visible inspection can also introduce variability owing to human blunders; incorporating automated inspection platforms complements accuracy tremendously although delivering objective assessments over timeframes vital for higher volume operations.

FAQ 6: What tuition tools are plausible for mastering approximately twine bonding?

Numerous online lessons exist covering the entirety from straight forward ideas of how wire bonding works simply by advanced issues like failure prognosis; academic papers published through universities typically provide insights into recent studies tendencies inside of this subject too!

Conclusion

Implementing Quality Control Measures in Wire Bonding Operations is just not simply an train but an fundamental detail that defines achievement in electronic production as of late. By targeting finished checking out methodologies combined with strong operational protocols—along ongoing instruction initiatives—establishments can support their production potential when minimizing possibility explanations associated with poor-first-class connections made via unreliable systems or technology feasible handy!

As we keep progressing in the direction of more and more problematic electronic designs pushing obstacles ahead—excellent assurance is still paramount! Thus Website link investing time into knowing those methods will yield dividends down line—now not just financially yet also recognition-clever among friends within this dynamic trade area!