Electrifying Connections: The Role of Vacuum Seals in Contemporary Innovation

In the current rapidly advancing technological landscape, the need for maintaining a controlled environment while facilitating electrical connectivity has grown more essential. Here is where the role of vacuum feedthroughs comes into play. Designed to assist with the transfer of electrical signals through a vacuum barrier, these devices are essential in various industries, from scientific research to manufacturing processes. Such devices empower systems to operate effectively in high-vacuum conditions while ensuring the integrity of both the electrical connections and the environment.

Vacuum feedthroughs are integral in applications such as particle accelerators, vacuum chambers, and semiconductor fabrication, where the delicate balance of pressure and electrical connectivity is paramount. By understanding how these components work and their significance in modern technology, we can appreciate the intricate connections that drive advancement and efficiency in a multitude of applications.

Comprehending Vacuum Seal Connectors

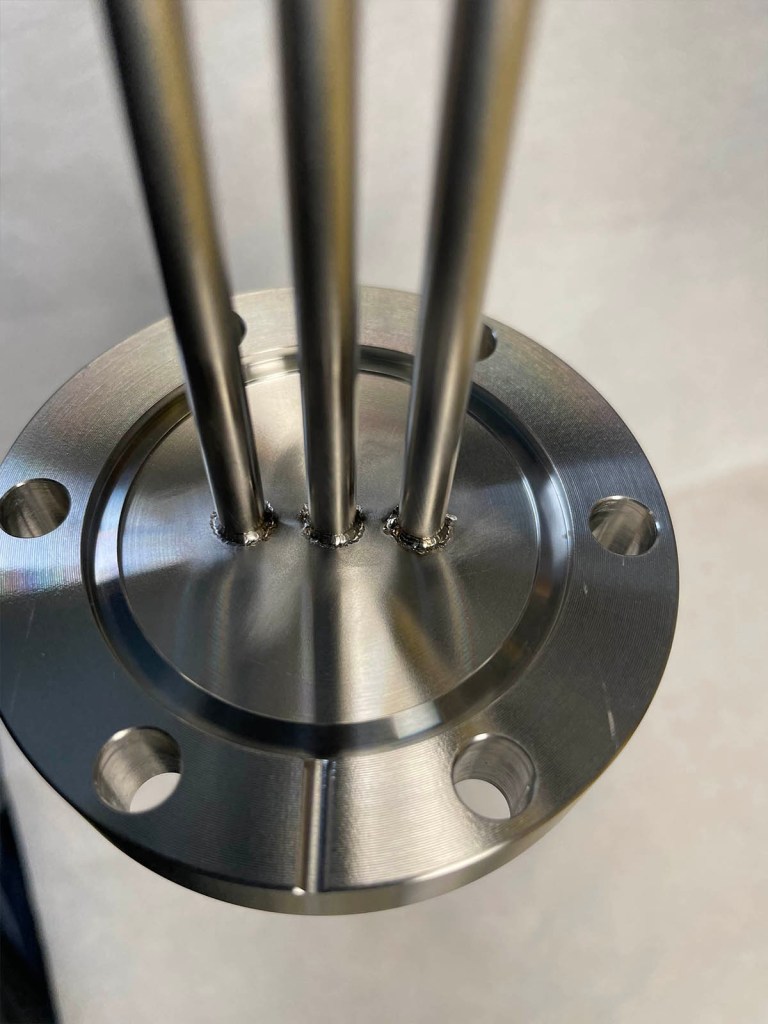

Vacuum feedthroughs are essential components that facilitate the transmission of electrical currents and power through the walls of a vacuum enclosure. They offer a reliable means of linking electrical devices to equipment that need to function in a vacuum environment. By using specific substances and design methods, these connectors guarantee that the integrity of the pressure is maintained while allowing for effective electric communication.

In different fields, vacuum feedthroughs are integral in domains such as semiconductor manufacturing, scientific investigation, and numerous industrial applications. They are constructed to endure harsh environments, including elevated temperatures and various levels of electromagnetic disruption, which makes vital for purposes that require accuracy and consistency. The capability to isolate signals within a vacuum enclosure guarantees that measurements remain exact and uncontaminated by external factors.

Different categories of vacuum feedthroughs exist, each tailored to distinct needs and working conditions. Typical arrangements include ceramic seals, metal seals, and glass isolators, providing flexibility in design and operation. Grasping the appropriate form of feedthrough for a specific use is vital for guaranteeing maximum performance and lifespan of the machinery in which they are used.

Uses in Contemporary Technological Advances

Vacuum feedthroughs play a crucial role in various advanced applications, enabling the transfer of electric signals and power while maintaining a vacuum environment. One significant area of use is in chip manufacturing. These feedthroughs allow for precise electrical connections to equipment such as ion implanters, plasma etchers, and deposition systems. By providing a controlled atmosphere, vacuum feedthroughs help enhance the quality and performance of semiconductor devices, which are foundational to current electronics.

Another crucial use of vacuum feedthroughs is in scientific, particularly in cryogenic systems and particle accelerators. In these environments, upholding ultra-high vacuum conditions is essential for best operation. Vacuum feedthroughs provide the necessary electrical and thermal connections to various components, such as sensors, detectors, and coils, without violating the vacuum integrity. This capability is vital for experiments that require high precision and reliability, such as those conducted in physics and material science.

Lastly, vacuum feedthroughs are integral in the field of space technology and satellite systems. Many satellite components must operate in a vacuum to work correctly, and vacuum feedthroughs enable the required electrical connections while protecting against environmental factors. They are used in sensor systems, communication devices, and power distribution units aboard satellites, ensuring that these critical systems operate efficiently in the harsh conditions of space. As advancements in technology continue, the demand for specialized vacuum feedthroughs is expected to increase, further enhancing their role in various advanced applications.

Future Trends and Developments

As markets continue to change, the requirement for more complex vacuum feedthroughs is poised to grow. Innovations are focusing on improving the robustness and dependability of feedthrough designs to withstand extreme conditions in industries like electronics manufacturing and space exploration. Material technology is paving the way for more lightweight, enhanced components that can maintain their stability at varying pressures and temperatures. This transition towards high-performance materials will drive the next generation of vacuum feedthroughs, allowing more optimized and longer-lasting equipment.

Additionally, the implementation of intelligent systems into vacuum feedthroughs is emerging. Sensors that observe performance, identify leaks, and provide real-time data will be more prevalent, boosting system dependability and facilitating predictive maintenance. These intelligent feedthroughs can notably reduce downtime and operating costs by permitting for proactive interventions before failures happen, thus improving the overall experience and performance of high-tech equipment.

Sustainability will also play a significant role in the next phase of vacuum feedthroughs. Manufacturers are more and more shifting on sustainable materials and manufacturing techniques to adhere to environmental standards. The shift towards eco-friendly practices is not just about meeting regulations; it reflects a growing awareness and accountability within the industry. As innovations advance, we can expect vacuum feedthroughs to become more resource-efficient, supporting to eco-friendly operations across different sectors, ultimately synchronizing progress with responsible practices.